Push-type multifunctional overflow-preventing fuel gas safety valve

A gas safety valve, multi-functional technology, applied in the direction of safety valve, function valve type, valve details, etc., to achieve the effect of convenient operation, quick return, excellent safety and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

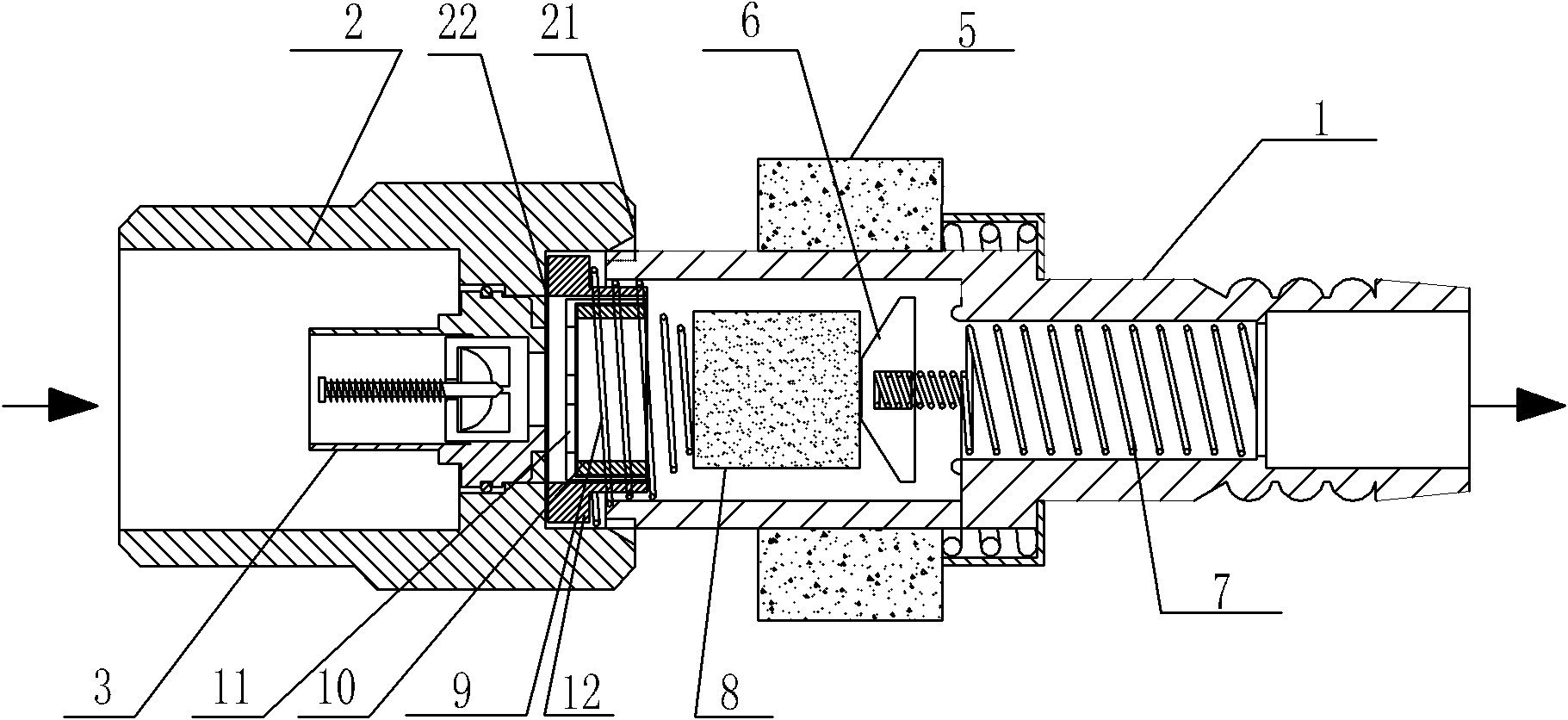

[0017] Such as figure 2 Shown, is the structural representation of the present invention.

[0018] Such as figure 2 As shown, the valve of the present invention includes a valve casing 1 made of non-magnetic material, and a valve joint 2 is screwed to the gas inlet end of the valve casing 1 . A magnetic core controller 5 is connected outside the valve housing. The joint between the valve joint 2 and the valve casing 1 is provided with an internal thread, and the gas inlet end of the valve casing 1 is provided with a matching external thread. The second end face 22 of the end.

[0019] According to the air flow direction, a positioning spring 9, a magnetic core 8, a sealing sheet 6 and a valve opening spring 7 are sequentially arranged in the valve chamber. The valve cavity is also provided with a positioning ring 12 near the valve joint, and a reset magnetic ring 10 is arranged in the positioning ring. The locating ring 12 is a cylindrical body with a reduced diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com