Inlet guide vane assembly

An air intake guide vane assembly and blade technology, which is applied to pump components, engine components, components of a pumping device for elastic fluids, etc., can solve the problems of difficult manufacturing, air tightness and appearance of external actuators, etc. Poor, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

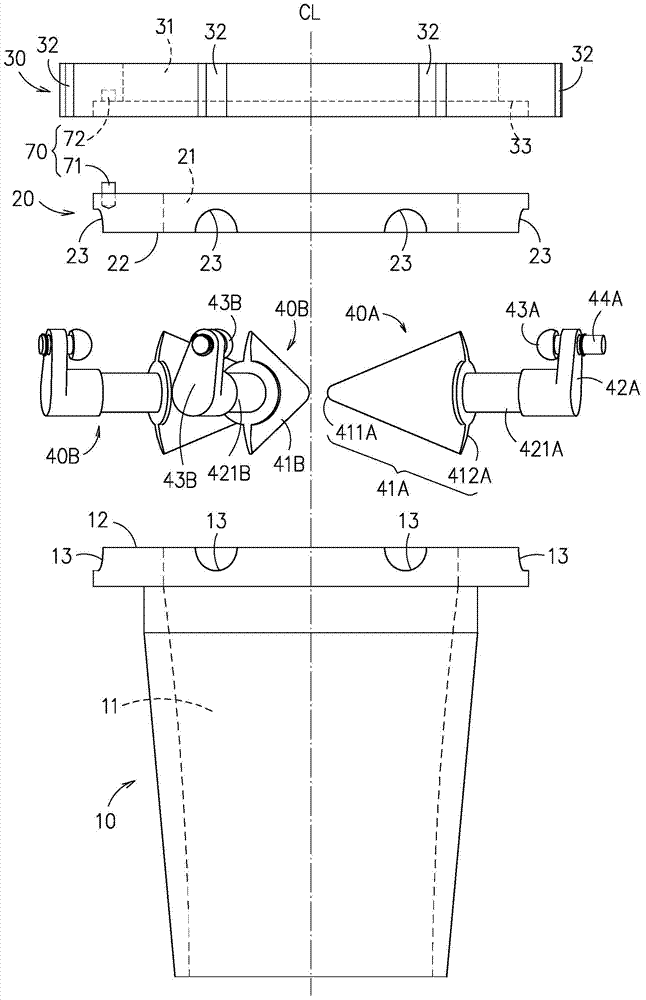

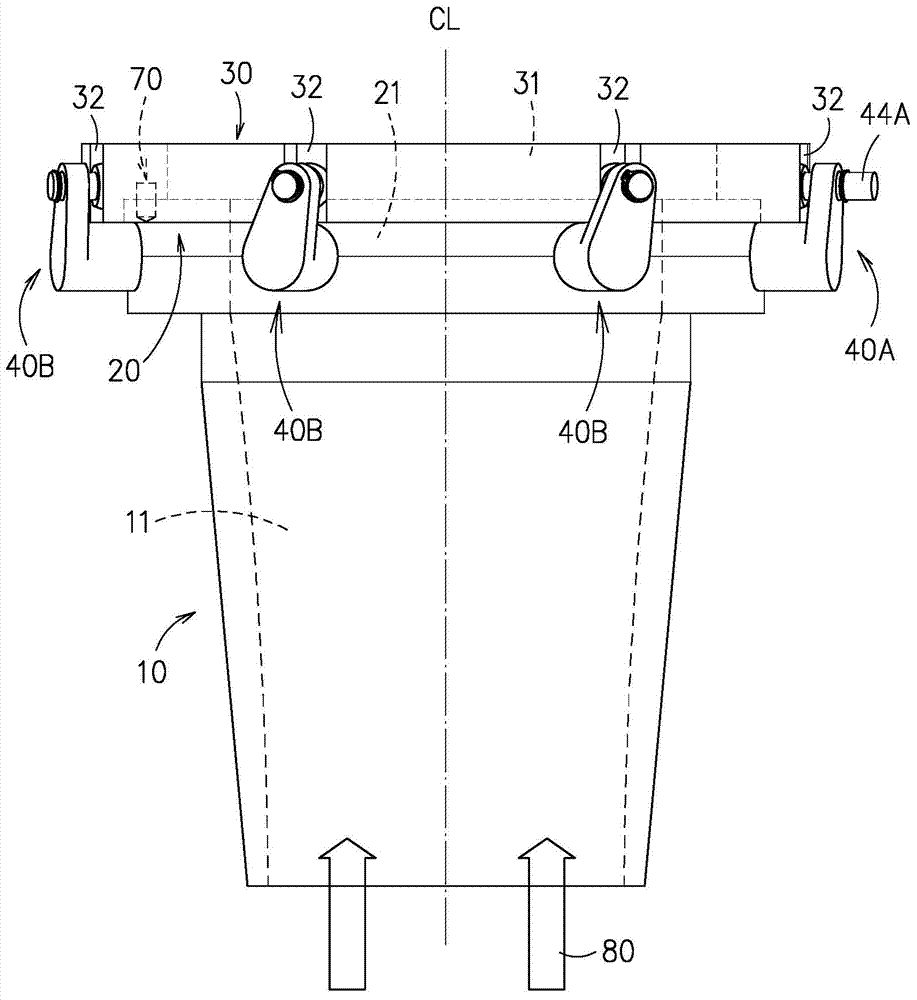

[0051] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only for auxiliary illustration, but the technical means of this case are not limited to the listed accompanying drawings .

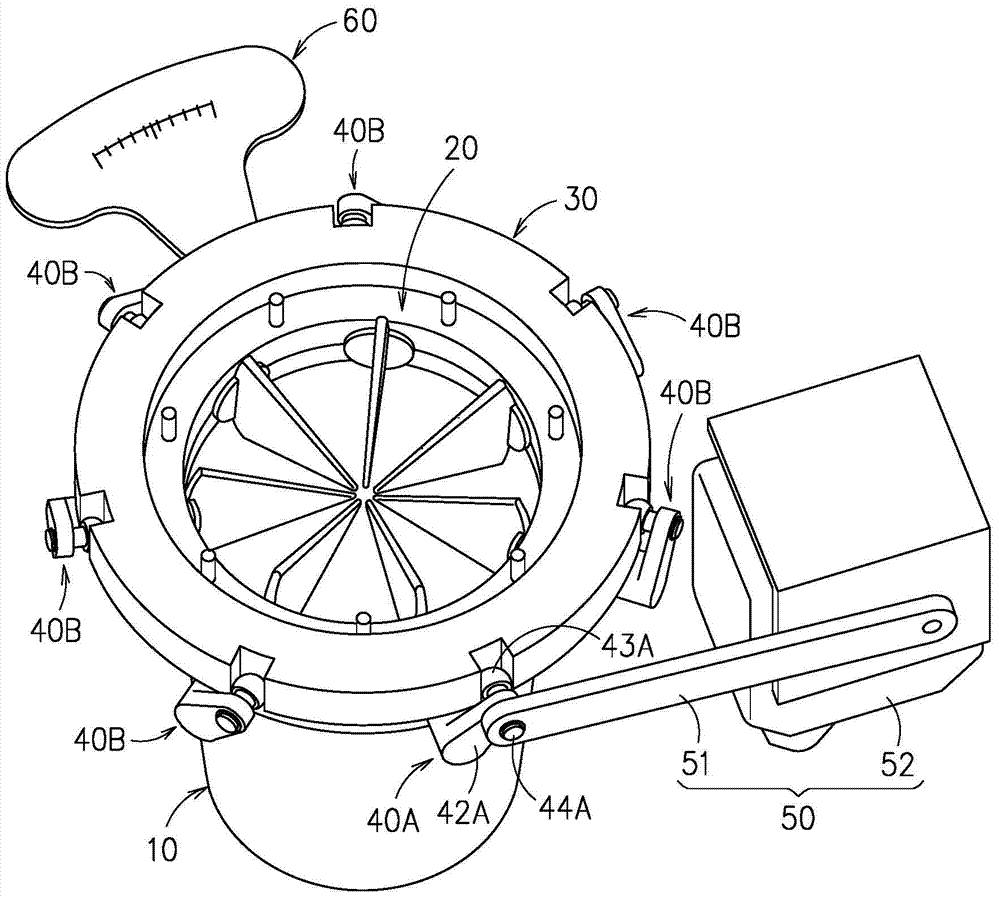

[0052] see Figure 1 to Figure 5 An embodiment of the air inlet guide vane assembly provided by the present invention is shown, which includes a housing 10, a fixed ring 20, a rotating ring 30, a plurality of vane devices 40A, 40B and a driving member 50; in addition, as figure 1 As shown, the present embodiment further includes a scale indicator 60, the scale indicator 60 is connected to the rotating ring 30, the setting of the scale indicator 60 depends on actual needs, and may not be provided, and the type of the scale indicator 60 and Any form figure 1 shown.

[0053] The outer shape of the housing 10 is a hollow cylindrical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com