Comprehensive air pressure test bed for vehicle-mounted steel tank

A comprehensive test bench and test bench technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring the rate of increase and deceleration of fluid, and using liquid/vacuum to measure liquid tightness, etc., can solve the problems of production and users Use safety hazards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

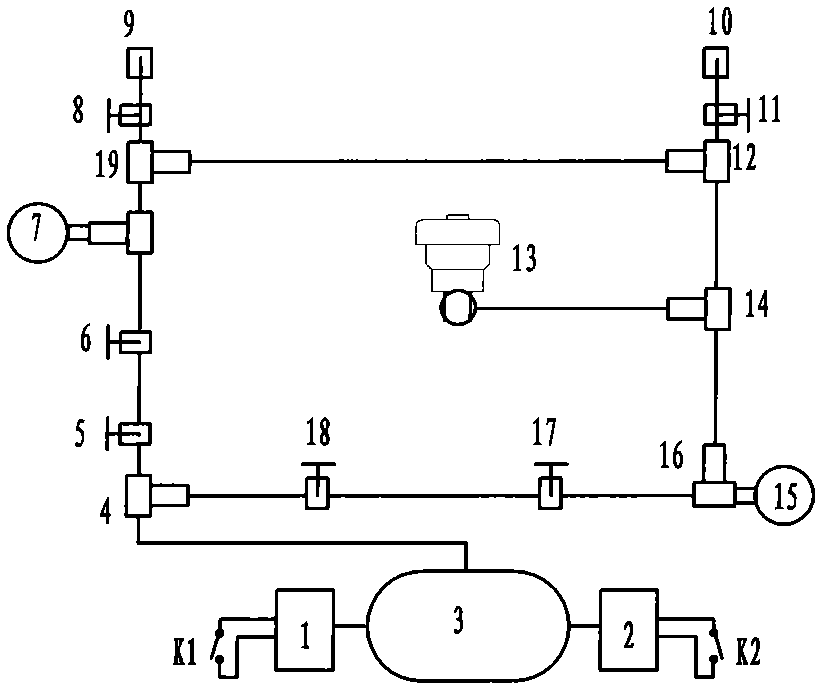

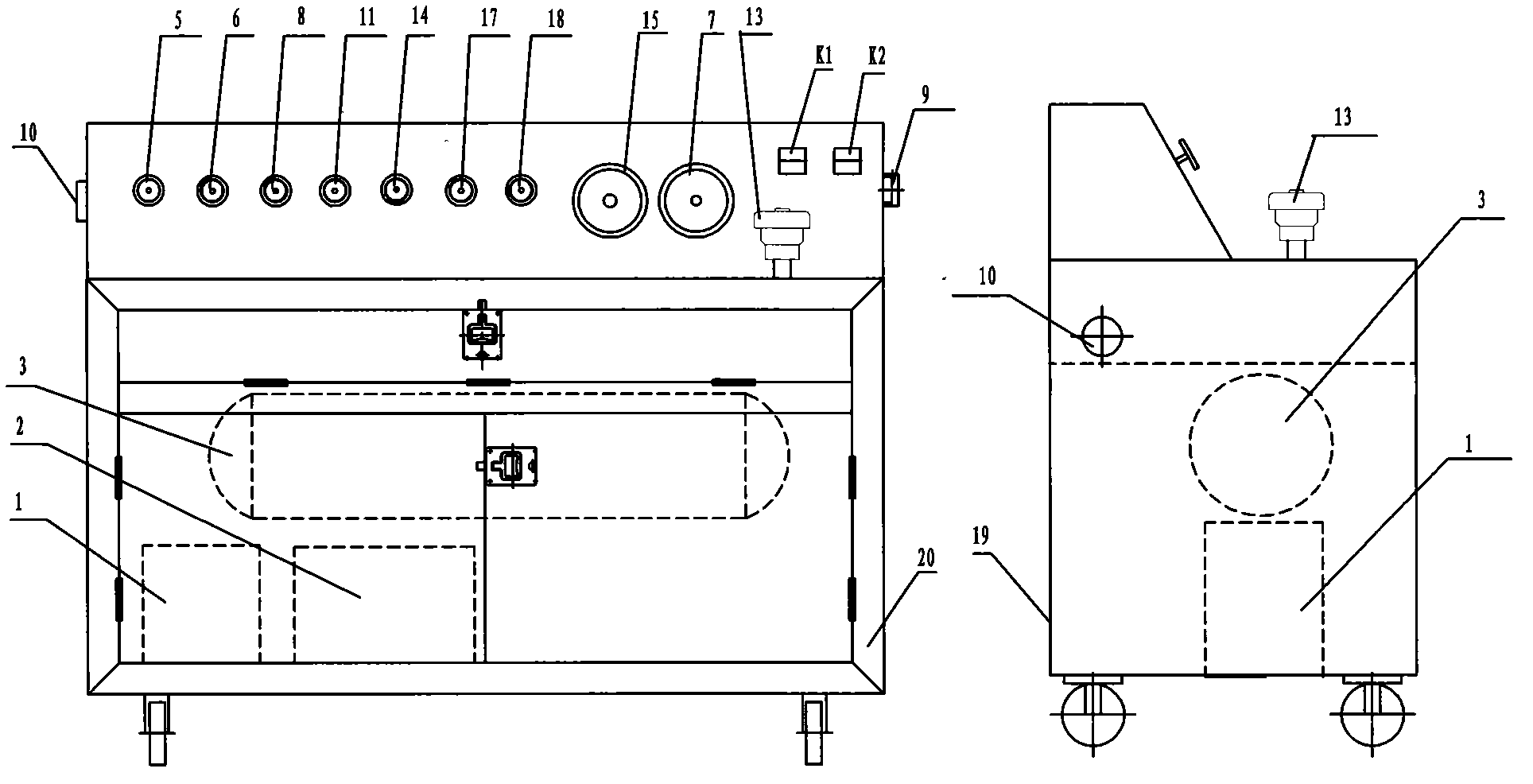

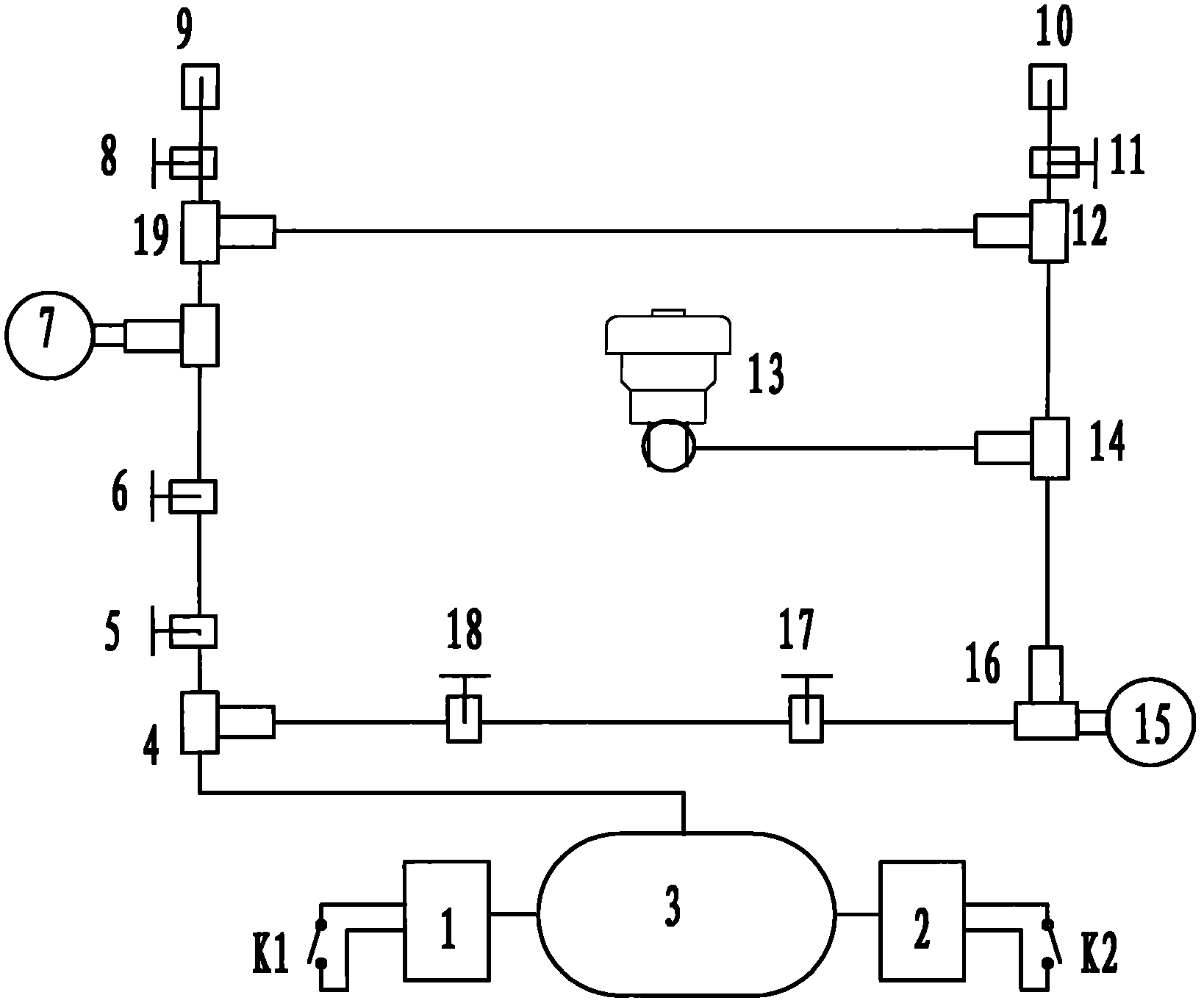

Method used

Image

Examples

Embodiment

[0025] 1) Positive and negative pressure inspection operation of the breathing valve:

[0026] (1) Turn off the power switch of the vacuum pump, turn the air-operated three-way valve 14 to the positive pressure detection position and connect with the breathing valve 13;

[0027] (2) The power supply of the booster pump is powered on, and the booster pump inflates the buffer gas tank;

[0028] (3) Open check valve 5;

[0029] (4) Adjust the pressure regulating valve 6, and observe the breathing valve 13 and the pressure gauge 7 to see if the exhaust can be exhausted within the specified pressure, if the exhaust is qualified;

[0030] (5) close check valve 5,

[0031] (6) Turn on the power supply of the vacuum pump, and the vacuum pump will evacuate the buffer gas tank,

[0032] (7) Open the one-way valve 18, observe the vacuum value of the vacuum gauge, and close the vacuum pump when the vacuum reaches the standard prescribed negative pressure;

[0033] (8) Rotate the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com