Anti-deformation aluminum-clad heat insulation door

A thermal insulation door, anti-deformation technology, applied in the door leaf and other directions, can solve the problems of curling, unenvironmental protection, easy deformation of thermal insulation doors, etc., and achieves remarkable effects, saving resources, and cooling off significantly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

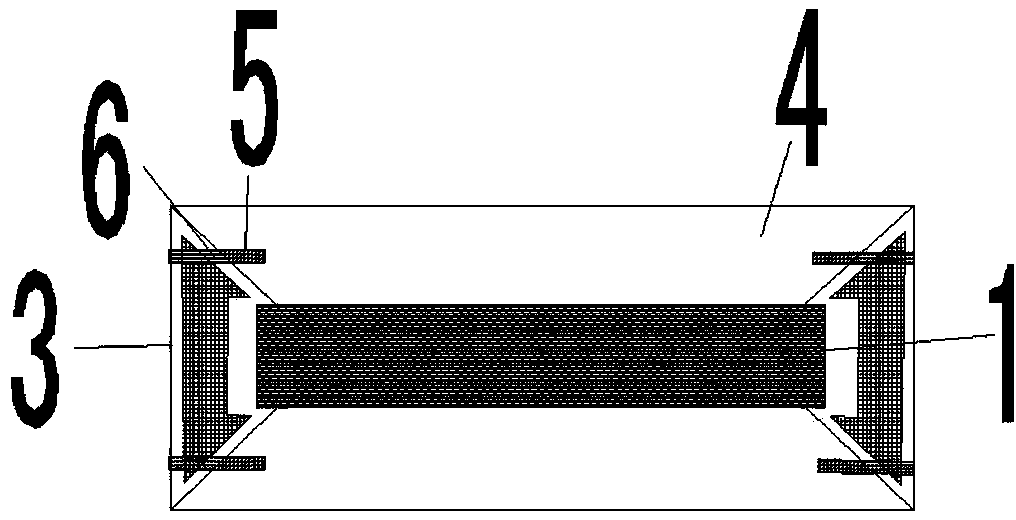

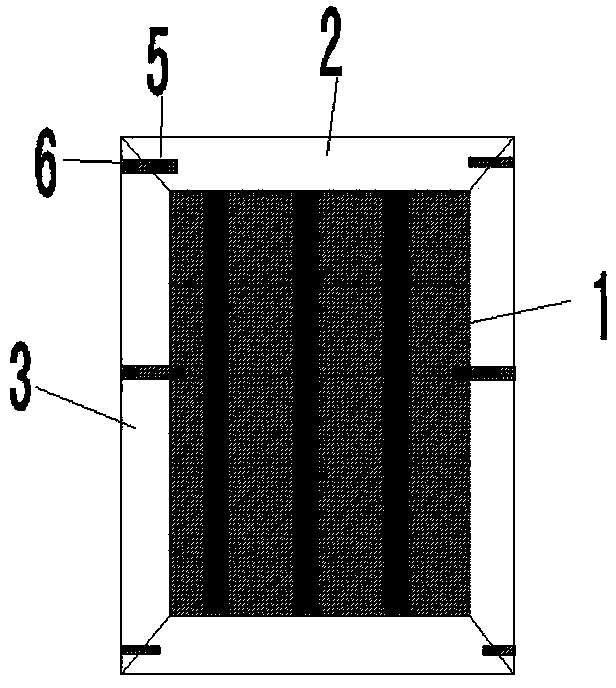

[0016] An anti-deformation aluminum-clad thermal insulation door, comprising a door core 1, an aluminum-clad wooden door horizontal frame 2, an aluminum-clad wooden door mullion 3, and a surface layer 4, wherein the door core 1, the aluminum-clad wooden door The wooden clad door mullion 3 and the facade 4 are connected by blind holes 5, through holes 6, bolts and nuts excavated on the aluminum clad wooden door horizontal frame 2, the aluminum clad wooden door mullion 3, the door core 1, and the facade 4. The door core 1 and the door surface 4 are provided with blind holes 5, and the aluminum-clad wooden door horizontal frame 2 and the aluminum-clad wooden door mullion 3 are provided with through holes 6 corresponding to the positions and sizes of the blind holes. The frame 2 and the mullion 3 of the aluminum-clad wooden door are connected by fixing bolts in the blind hole 5 and the through hole 6 , and nuts are arranged in the blind holes on the door core 1 and the door surfa...

Embodiment 2

[0018] The horizontal frame 2 of the aluminum-clad wooden door and the mullion 3 of the aluminum-clad wooden door are in a concave structure, the interior is made of wood, and the outer layer is made of aluminum plate and plastic.

Embodiment 3

[0020] After the aluminum-clad wooden door horizontal frame 2 and the aluminum-clad wooden door mullion 3 have a concave structure, they are cut at an angle of 45 degrees to both sides based on the notch, and the joint between the surface layer and the door frame is also cut at 45 degrees accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com