Manufacturing method of environment-friendly energy-saving solid wood composite multilayer decoration board

A technology of solid wood composite, environmental protection and energy saving, which is applied in the jointing of wooden veneers, wood treatment, manufacturing tools, etc. It can solve the problems of poor waterproof performance, non-environmental protection of composite boards, easy shrinkage or expansion, etc., to solve the problem of variable type Cracking, cooling effect is remarkable, the effect of promoting low-carbon economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for manufacturing an environmentally friendly and energy-saving solid wood composite multi-layer decorative board, comprising the following steps: firstly, the logs are boiled for softening treatment, the softened logs are rotary cut into veneers, and then the veneers are dried;

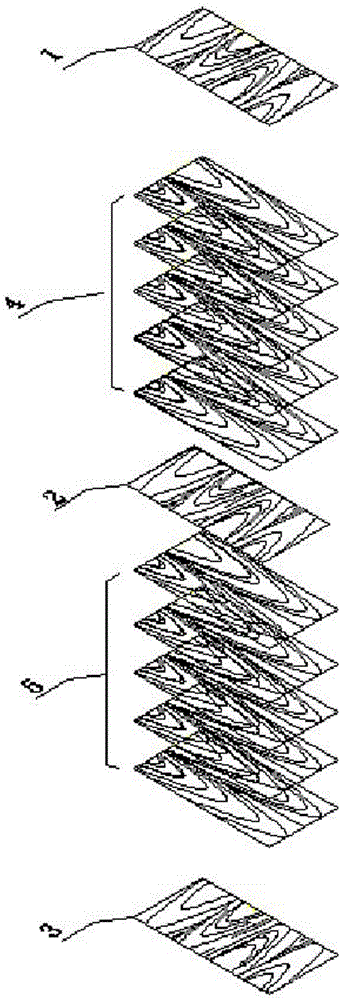

[0026] The second step is to divide the wood texture of the veneer into horizontal grain arrangement and longitudinal grain arrangement, and set the veneers arranged in horizontal grain arrangement and longitudinal grain arrangement in a manner of overlapping 90° vertical cross distribution and glue the surface to be bonded;

[0027] The third step is to put the veneers that have been arranged and coated with glue into a hot press, press high temperature, high pressure, and shape into a multi-layer board, and place it for more than 10 days for static health preservation;

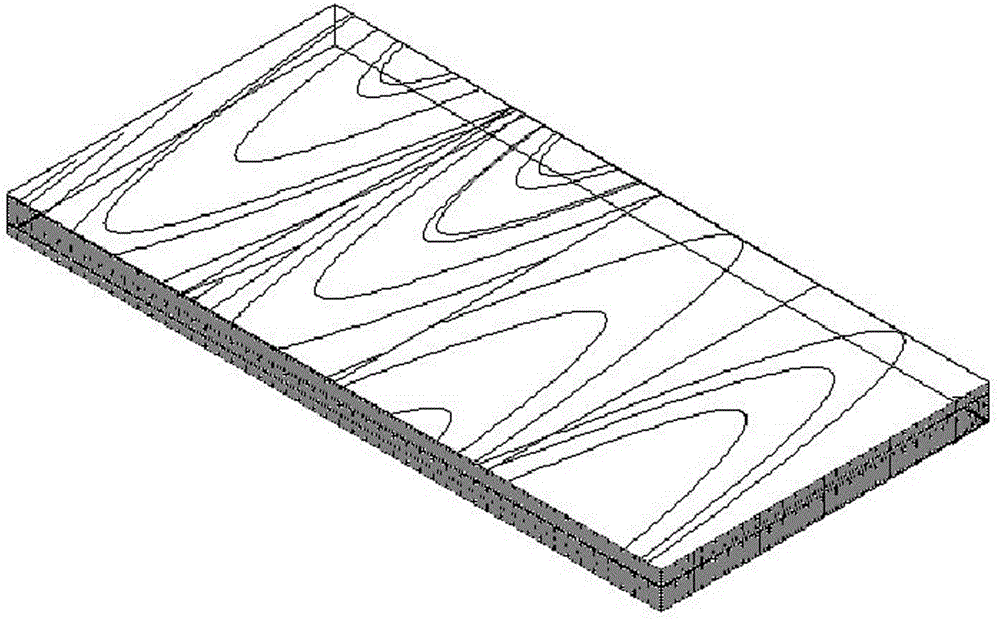

[0028] The fourth step is to saw off the four sides of the well-preserved multi-layer board, sand it with ...

Embodiment 2

[0031] The production method of the environmental protection and energy-saving solid wood composite multi-layer decorative board described in this embodiment, the first step is to cook the logs for softening treatment. Spray steam, keep warm for 10 hours when the temperature is raised to 50-60°C, and keep warm for 10 hours when the temperature is raised to 70-80°C, and then slowly drop to room temperature; the softened logs are cut into veneers by rotary cutting. Rotary cut into 1.8-2mm veneer; the veneer is dried by hot pressing.

Embodiment 3

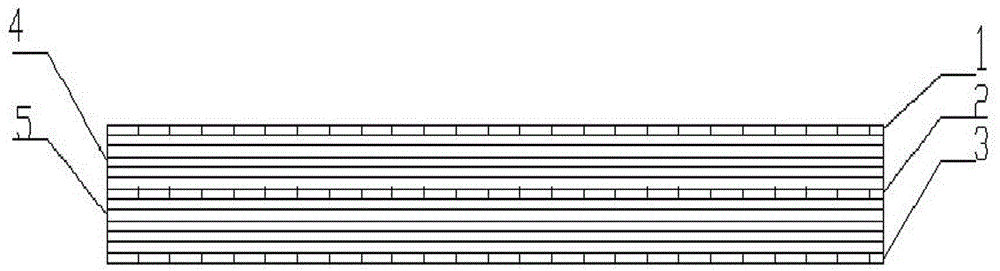

[0033] The manufacturing method of the environmental protection and energy-saving solid wood composite multi-layer decorative board described in this embodiment, as attached figure 2 As shown, in the second step, the wood texture of the veneer is divided into horizontal grain arrangement and longitudinal grain arrangement. Put the veneer with horizontal grain arrangement on one layer, and put a layer of veneer with vertical grain arrangement on top of the veneer with horizontal grain arrangement. , vertically cross and overlap 90° and arrange upwards to reach the required number of layers, apply glue on the inner surface of the top veneer and bottom veneer, and apply glue on both sides of the middle veneer. attached figure 2 The veneer arranged in the middle horizontal texture is placed in layer 1, the core board in the first layer is 4, the veneer in the middle layer is arranged in the horizontal texture 2, the core board in the second layer is 5, and the veneer 3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com