Inorganic non-combustible safe aluminum composite panel

An aluminum composite panel, safety-level technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

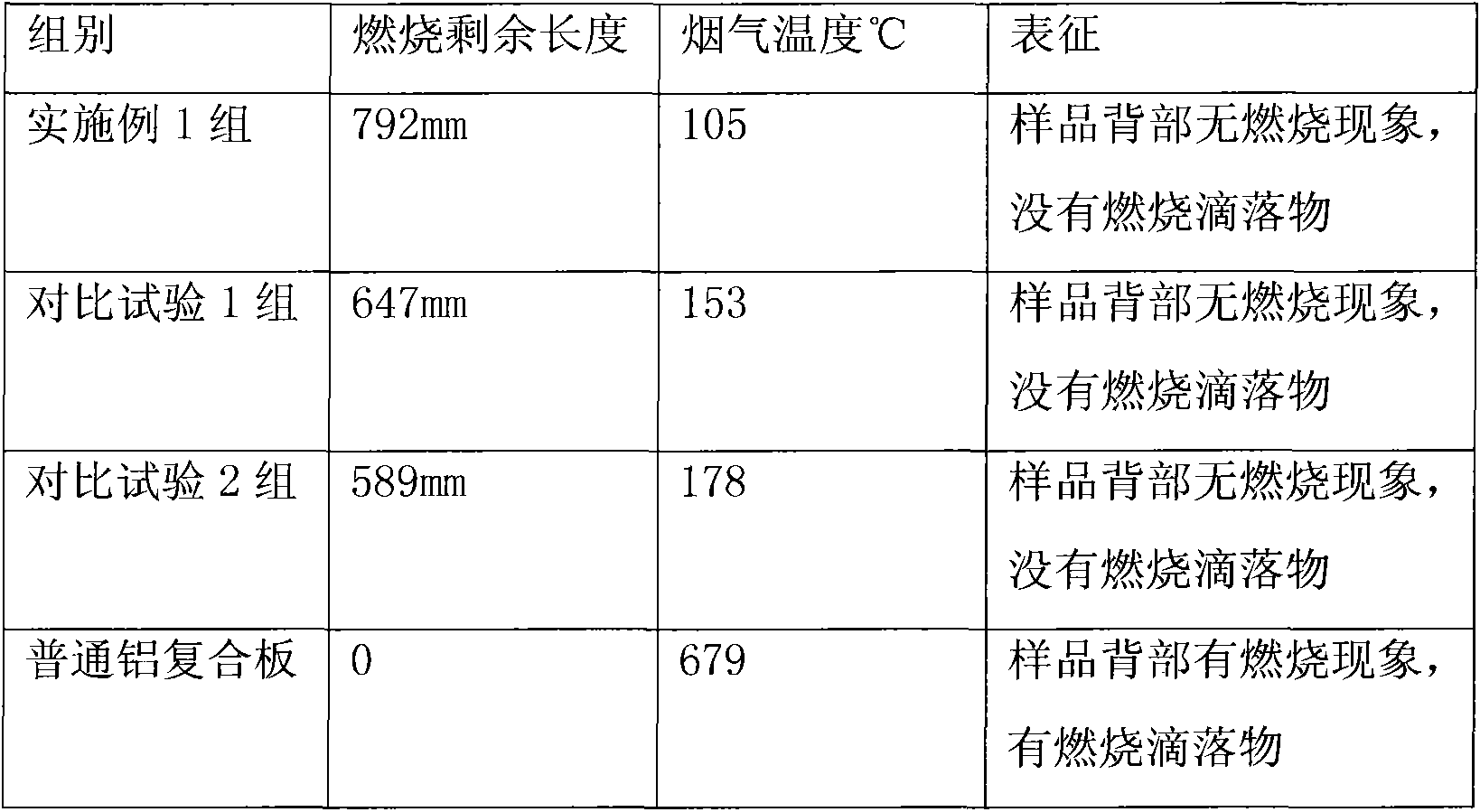

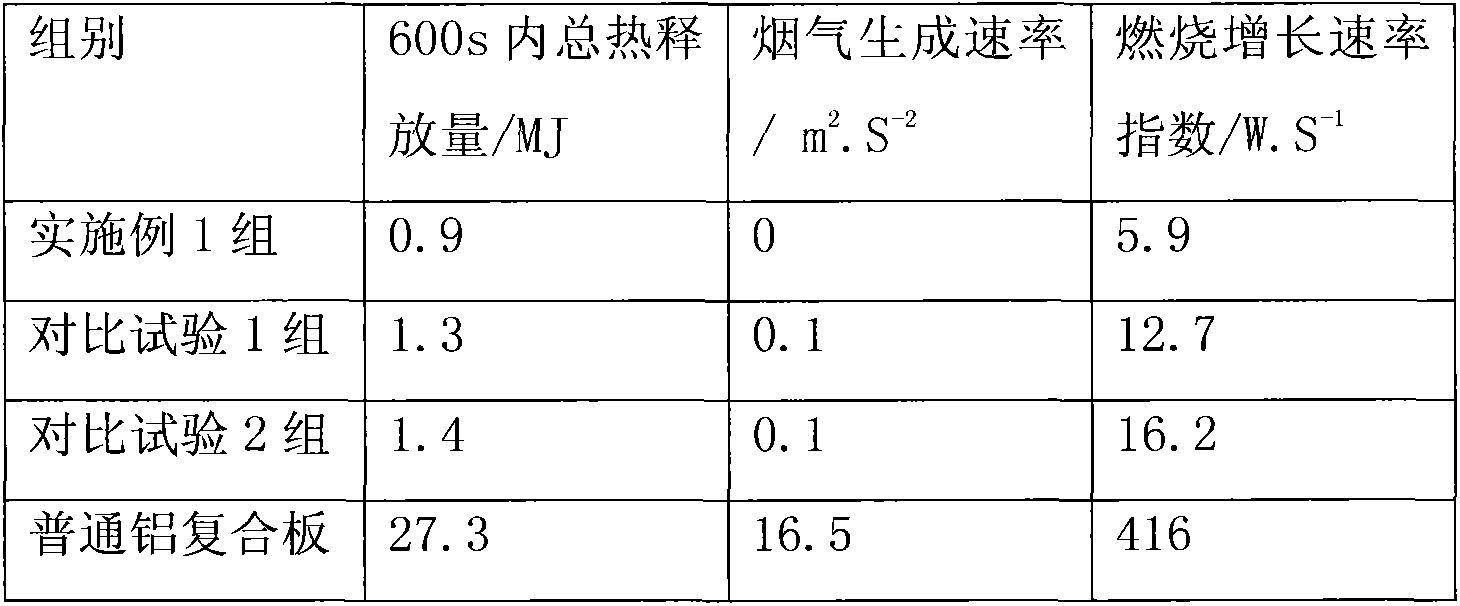

Examples

Embodiment 1

[0018] An inorganic non-combustible safety-grade aluminum composite panel, which consists of an aluminum base material, an inorganic core plate and an aluminum base material from top to bottom, and is prepared by hot-pressing continuous composite molding. The gap between the aluminum base material and the inorganic core plate is And between the inorganic core board and the aluminum substrate, it is made of polymer bonding material, and the thickness of the polymer bonding material is 0.1mm;

[0019] The above-mentioned inorganic core board is prepared from powder, white latex, polypropylene alcohol and water, wherein the weight ratio of powder, white latex, polypropylene alcohol and water is 89:7:4:20; the powder is made of hydrogen oxidized Aluminum, magnesium oxide, silicon carbide powder, anhydrous calcium sulfate and borax are prepared according to a weight ratio of 73:11:7:7:2; the particle diameters of the silicon carbide powder and borax are controlled above 100 mesh; I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com