Water-retention and water-permeable brick and preparation method thereof

A technology of permeable bricks and cement, applied in sustainable waste treatment, solid waste management, climate sustainability and other directions, can solve the problems of affecting aesthetics, high laying cost, no water-retaining and permeable function, and non-slip, etc. The effect of low cost and clean ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

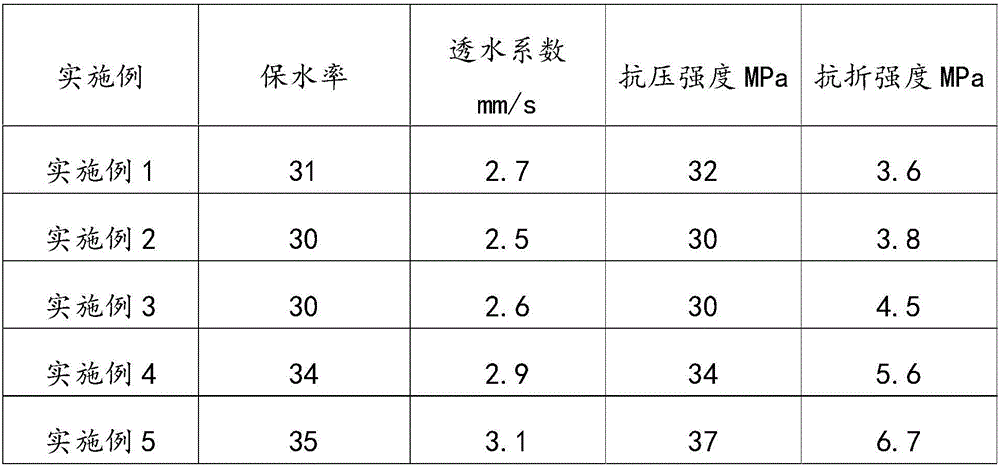

Examples

Embodiment 1

[0056] A method for preparing water-retaining and permeable bricks. In terms of parts by mass, 50 parts of stone materials with a particle size below 2mm and 5 parts of P.I42.5 cement cement are pre-configured, fully mixed and stirred evenly with a brick making machine; and then pressed Add 1 part of hydrolyzed polymaleic anhydride, 0.1 part of calcium chloride and 10 parts of water respectively, mix thoroughly and evenly, discharge the material, press molding, demoulding, and curing for 7 days to obtain a water-retaining and permeable brick.

Embodiment 2

[0058] A method for preparing water-retaining and permeable bricks. In terms of parts by mass, 120 parts of stone materials with a particle size of 0.1-2mm or less and 25 parts of P.II42.5 cement cement are pre-configured and fully mixed with a brick making machine. Then add 2 parts of hydrolyzed polymaleic anhydride, 1 part of sodium sulfate and 25 parts of water respectively in proportion, fully mix and stir evenly, discharge the material, press molding, demoulding, and curing for 8 days to obtain a water-retaining and permeable brick.

Embodiment 3

[0060] A method for preparing water-retaining and permeable bricks. In terms of parts by mass, 70 parts of stone materials with a particle size of 1-2 mm or less and 10 parts of P.S42.5 cement cement are pre-configured, and fully mixed and stirred evenly with a brick making machine; Then add 1.2 parts of hydrolyzed polymaleic anhydride, 0.3 parts of calcium nitrate and 15 parts of water respectively in proportion, mix thoroughly and evenly, discharge the material, press molding, demoulding, and curing for 9 days to obtain a water-retaining and permeable brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com