Preparation method of pore-opening foamy copper having controllable porosity and pore diameter

An open-cell foam and porosity technology, applied in the field of metal manufacturing, can solve problems such as affecting material properties and applications, increasing the complexity and construction cost of preparation equipment, and the influence of copper matrix, achieving excellent appearance and performance, avoiding thermal stress. , the effect of shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

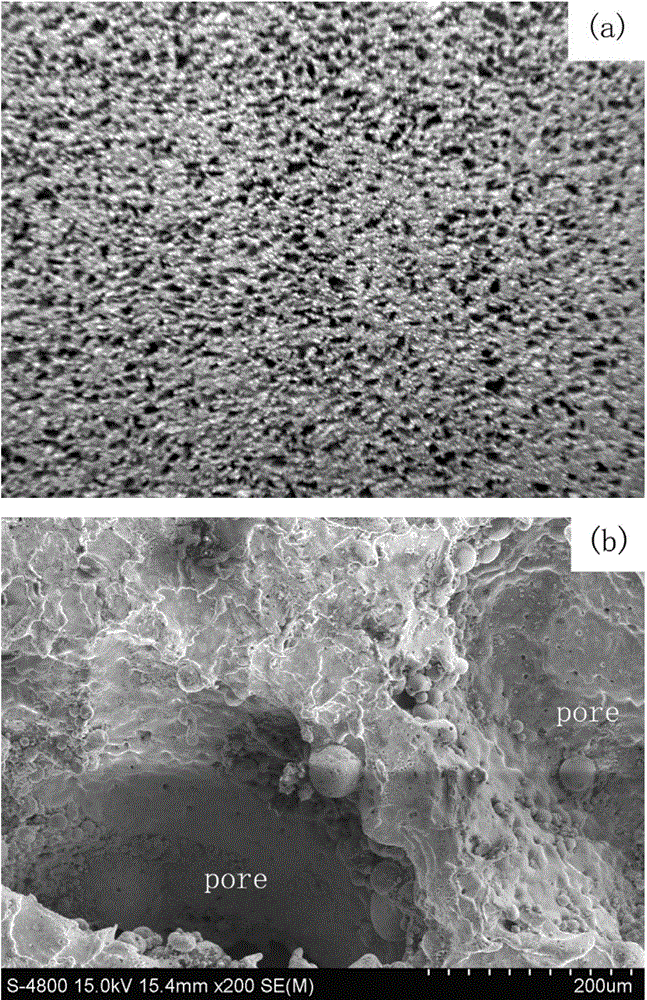

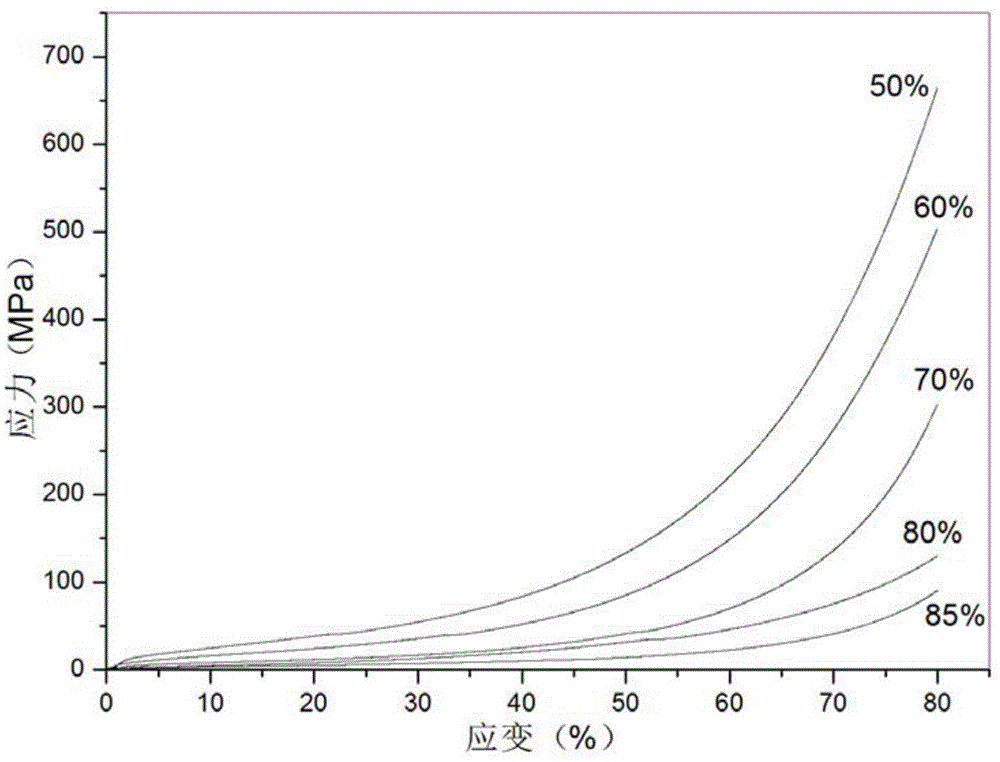

Embodiment 1

[0033] The first step, pretreatment of rock sugar particles

[0034] Rock sugar particles are crushed and sieved with different particle sizes to select rock sugar particles with an average particle size of 0.2mm;

[0035] The second step is to prepare the green body

[0036] The rock sugar granules obtained from the first step of processing and sieving are evenly mixed with 40 μm pure copper powder, and at the same time, an additive absolute alcohol of 2% of the total mass of the above-mentioned pure copper powder and rock sugar granules is added, wherein the rock sugar granules have a volume of 50% of the sum of the volume of particles and pure copper powder, the homogeneous mixture is loaded into a pressing mold, and the unidirectional pressure is pressed to 250MPa to obtain a green body;

[0037] The third step, the dissolution of rock sugar particles

[0038] Rinse the green body prepared in the second step in boiling water to dissolve the rock sugar particles. The wash...

Embodiment 2

[0043] The first step, pretreatment of rock sugar particles

[0044] The rock sugar particles are crushed and screened with different particle sizes, and the rock sugar particles with an average particle size of 0.4mm are selected;

[0045] The second step is to prepare the green body

[0046] The rock sugar granules obtained from the first step of processing and sieving are evenly mixed with 75 μm pure copper powder, and at the same time, an additive absolute alcohol of 3% of the total mass of the above-mentioned pure copper powder and rock sugar granules is added, wherein the rock sugar granules have a volume of rock sugar 50% of the sum of the volume of particles and pure copper powder, the homogeneous mixture is loaded into a pressing mold, and the unidirectional pressure is pressed to 300MPa to obtain a green body;

[0047] The third step, the dissolution of rock sugar particles

[0048] Rinse the green body prepared in the second step in boiling water to dissolve the roc...

Embodiment 3

[0053] Other steps are the same as in Example 2, except that the volume of the rock sugar particles is 60% of the sum of the rock sugar particles and the volume of pure copper powder, and the resulting copper foam product has an open-cell structure, with an average porosity of 60% and an average pore diameter of 0.4mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com