Pressure mounting device and pressure mounting method

An installation device and pressure technology, applied in electrical components, electrical components, etc., can solve the problems of low curing speed of thermally conductive adhesive, low reliability, limited space between chips, etc., to improve practicability and versatility, and ensure flexibility. and versatility, the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

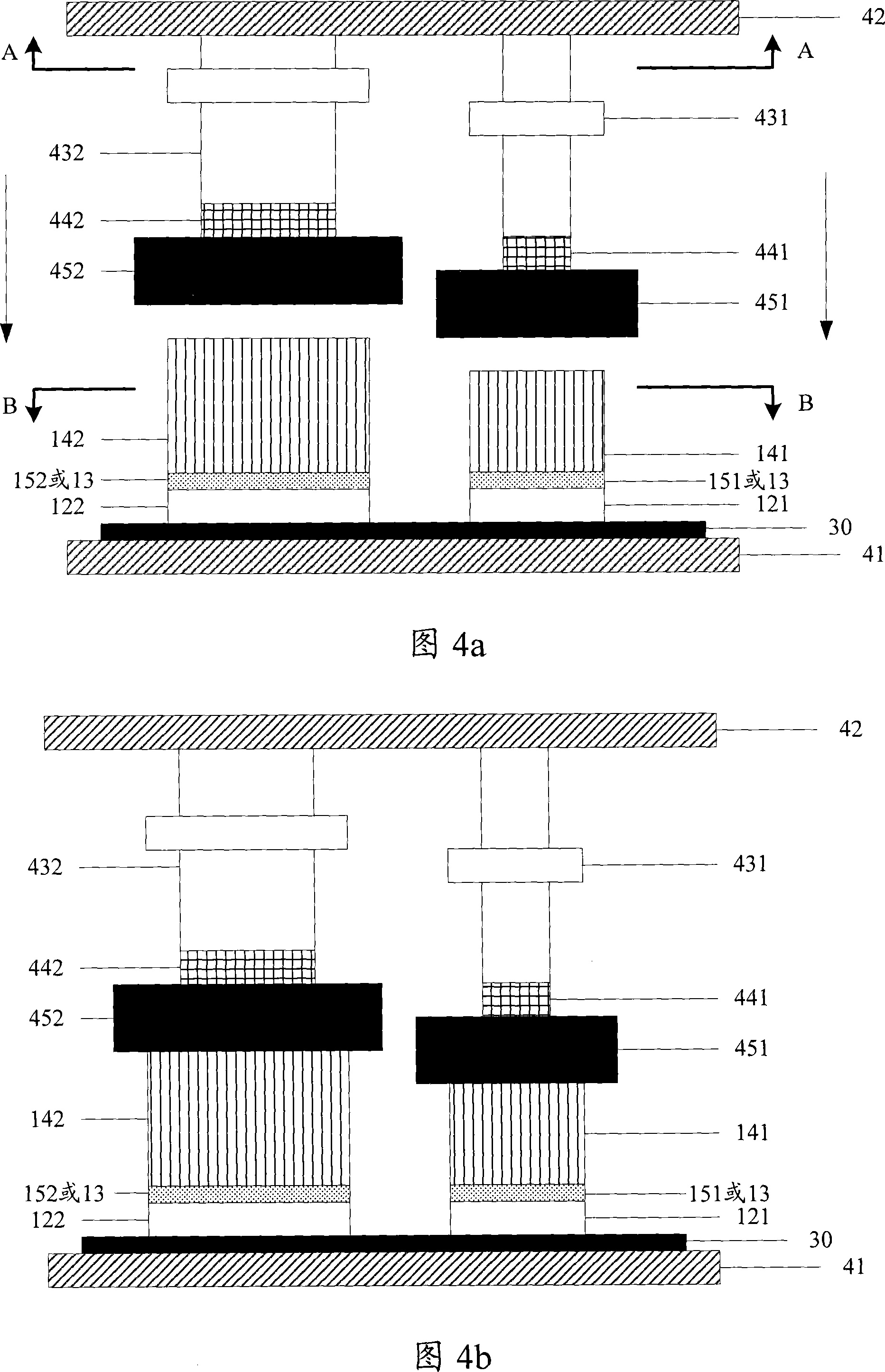

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0043] In this embodiment, a pressure component is set at the position corresponding to each installation position, and at least two parts to be installed that are stacked up and down and need to be bonded are placed on the installation position, and each The parts to be installed at the installation position apply pressure to realize the adhesive pressure installation of the parts to be installed.

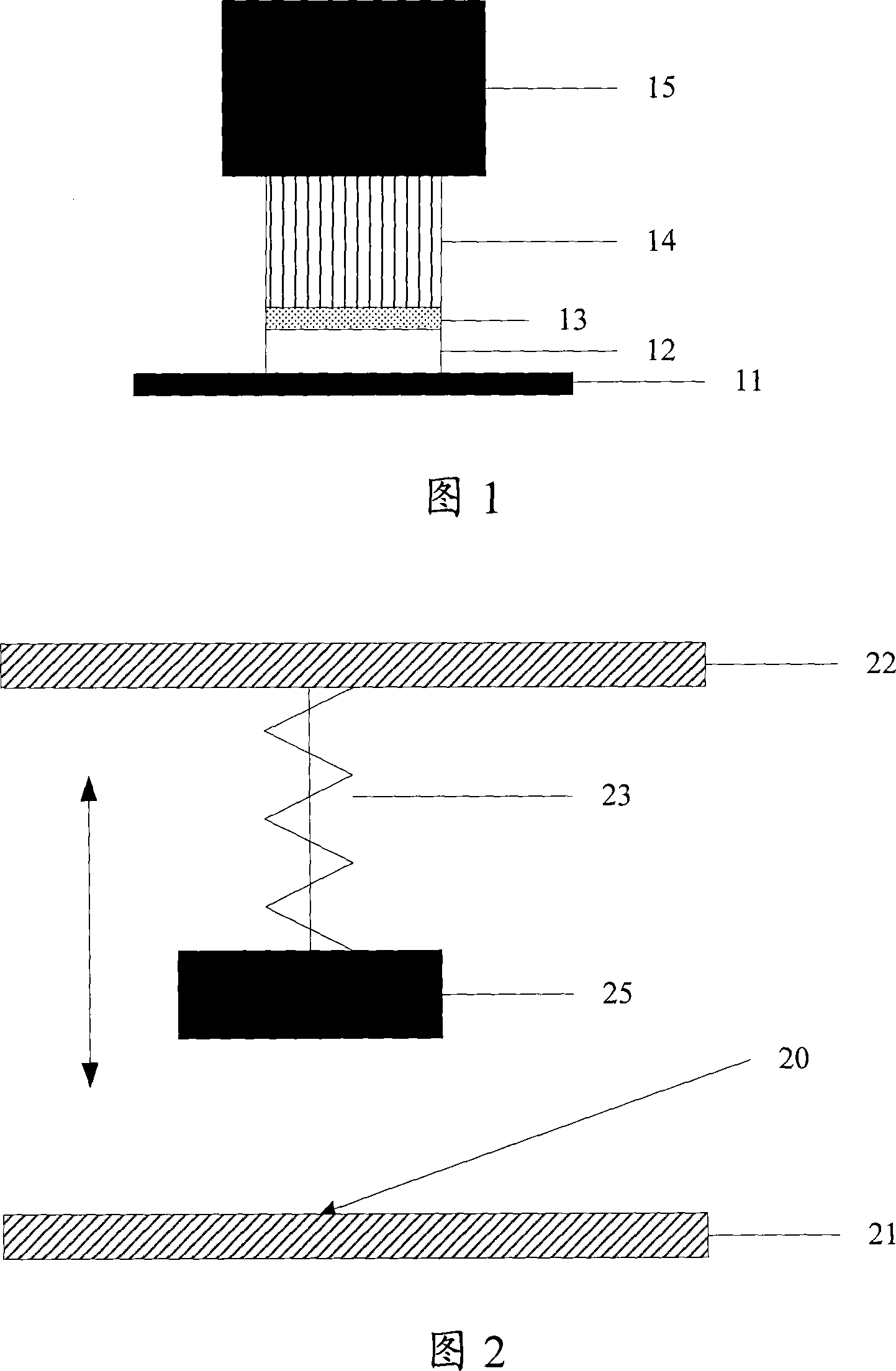

[0044] Wherein, taking installing a heat sink on a PCB as an example, the installation position is predetermined according to the chip position on the PCB where the heat sink needs to be installed. Different PCBs or different chips that need to be installed with heat sinks correspond to different heat sink installation positions.

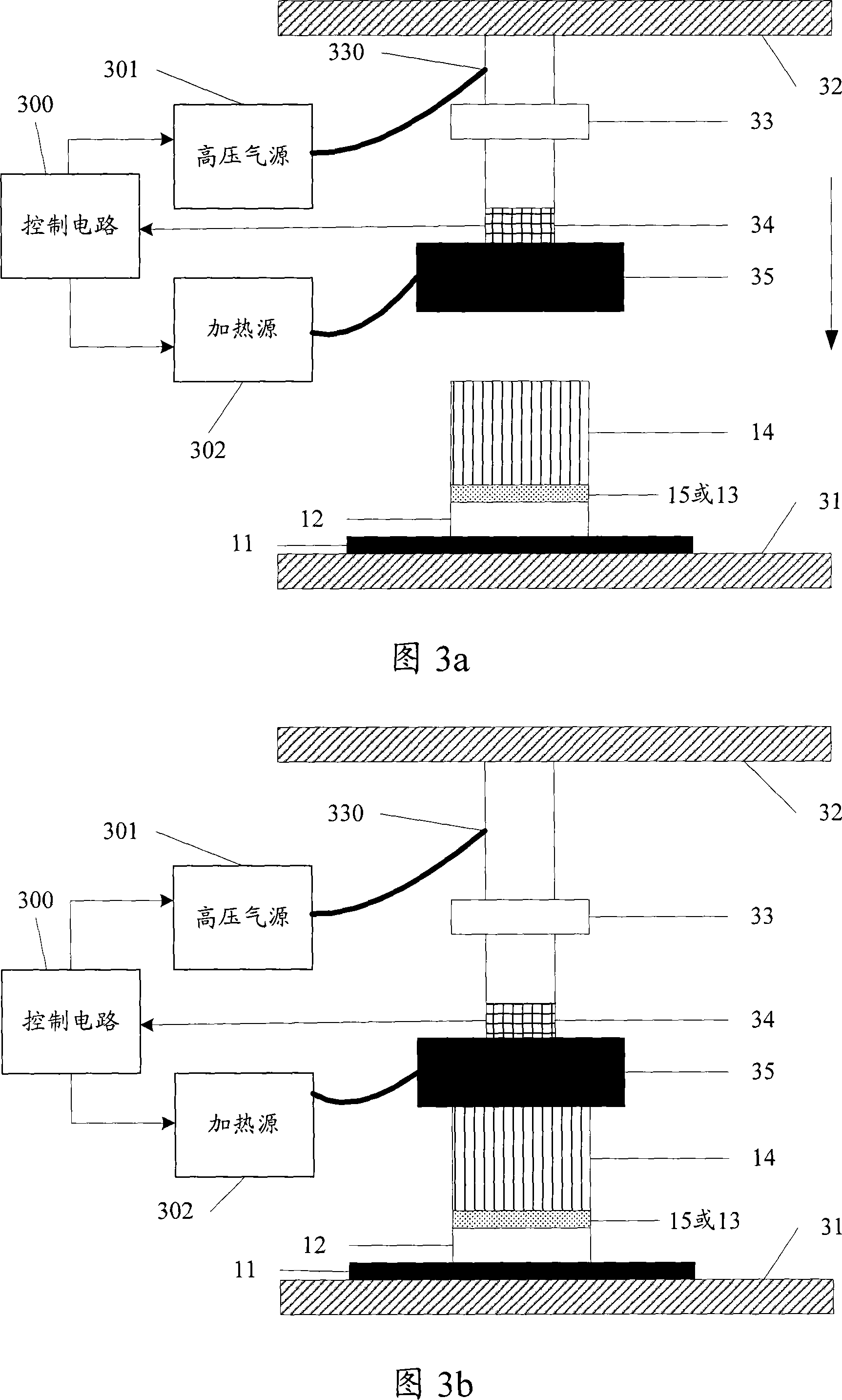

[0045] Fig. 2 is an exem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com