Glue-spray type wireless glue binding machine

A wireless glue binding machine and glue-spraying technology, applied in bookbinding, binding adhesives, printing, etc., can solve problems such as uneven glue layer thickness, long melting time, and difficult control of glue temperature. Good bonding performance, short melting time, and high-quality adhesive binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

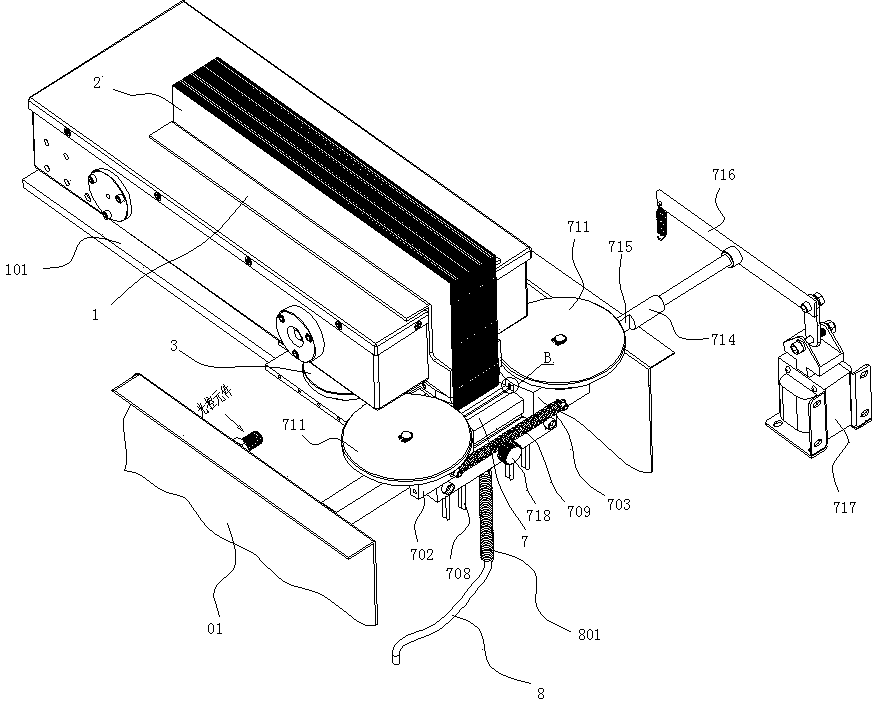

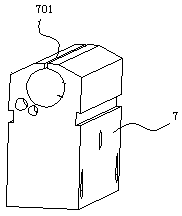

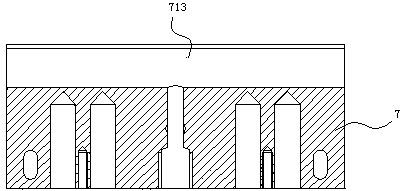

[0027] Such as Figures 1 to 8 As shown, a glue-spraying wireless adhesive binding machine of the present invention includes a frame 01, a sheet stack clamping mechanism 1 arranged on the frame 01, a milling cutter mechanism 3 for milling a notch on the lower side of the sheet stack 2, and gluing mechanism, a cover mechanism, and a control device for controlling the action of the above-mentioned mechanism. The gluing mechanism includes: a nozzle 7, a vertically arranged cylindrical glue tank 9, the top of the nozzle 7 is an inline spray slit 701, and the inline spray slit 701 is arranged along the left and right direction and is located on the page At the front and bottom of the lower side of the stack 2, by adjusting the height of the reference platform 101 of the stack clamping mechanism 1, the distance between the lower side of the stack 2 and the in-line spray slit 701 can be controlled, thereby controlling the glue spraying thickness of the adhesive , the nozzle 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com