Spray nozzle mechanism of glue-spray type wireless glue binding machine

A wireless glue binding machine and glue spraying technology, which is applied in the direction of spraying devices, spraying devices, and adhesives for binding, etc., can solve the problem of insufficient bonding between hot melt adhesives and paper fibers, affecting the quality of cover binding, and the height of edges unevenness and other problems, to achieve the effect of improving the quality of glue binding, simple structure and sufficient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

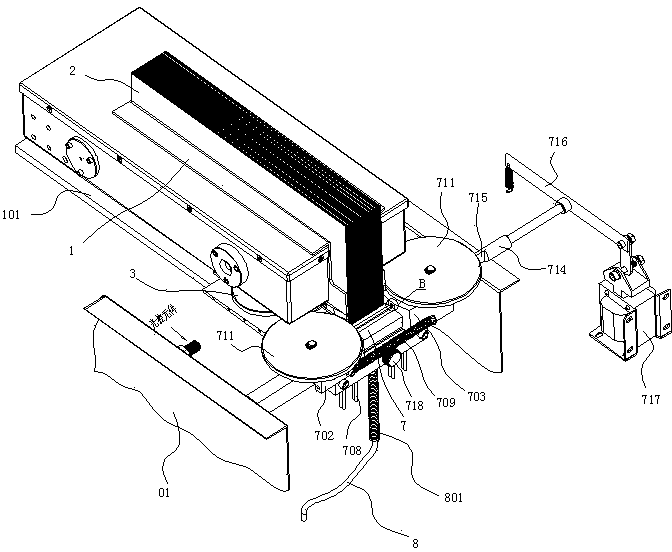

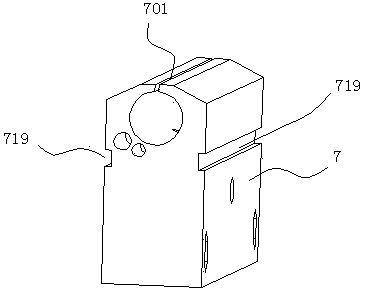

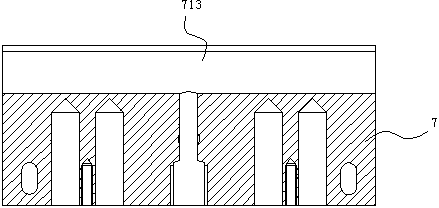

[0030] Such as Figures 1 to 9As shown, the nozzle mechanism of a glue-spraying wireless adhesive machine of the present invention includes a nozzle 7, and the top of the nozzle 7 is a straight spray slit 701, and a glue control valve is arranged in the nozzle 7 to control the flow into the glue. Describe the on-off of the hot-melt glue liquid of in-line spray slit 701, described glue control valve is opened in the circular through-hole 713 of in-line spray slit 701 lower ends and is installed in this circular through-hole 713 The rotating shaft 714 is formed, and the rotating shaft 714 and the circular through hole 713 are rotatably and sealingly matched, and the middle section of the rotating shaft 714 is provided with a cutout 715 ( figure 1 The slit 715 is shown. After the actual assembly, the slit 715 is located in the middle of the circular through hole 713 and cannot be seen), the width of the slit 715 is smaller than the diameter of the rotating shaft 714, and the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com