Flexible connector assembly for flexible spraying pipe of solid rocket engine and manufacture method thereof

A technology of flexible nozzles and flexible joints, which is used in machines/engines, jet propulsion devices, etc., can solve the problems of easy cracking of elastic parts and reinforcement parts, air leakage on the bonding surface, low bonding strength, etc. The effect of low cycle and development cost, good sealing performance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

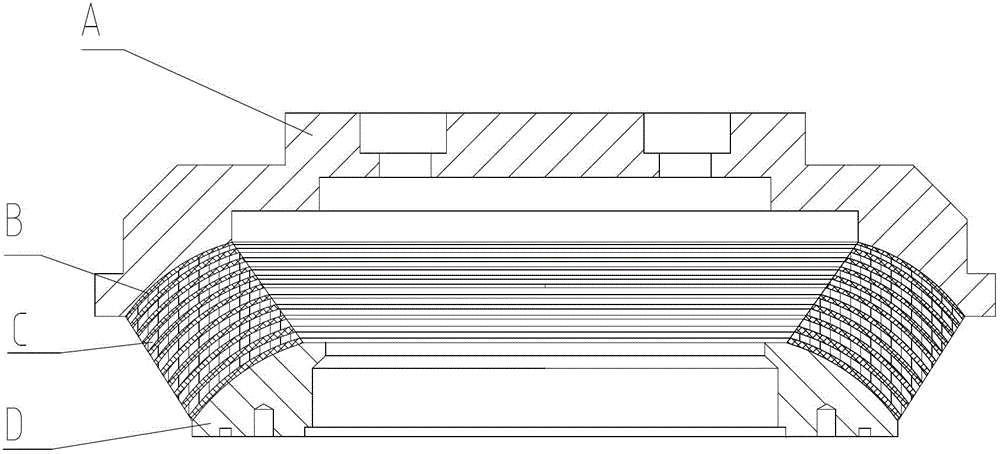

Embodiment 1

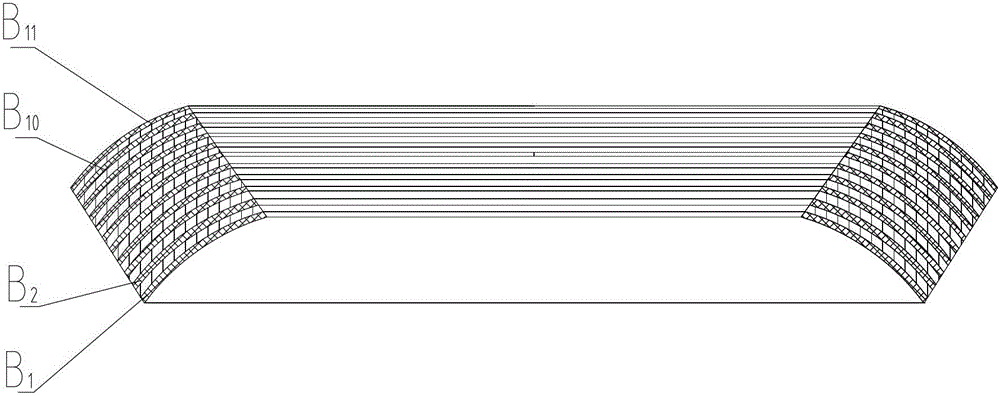

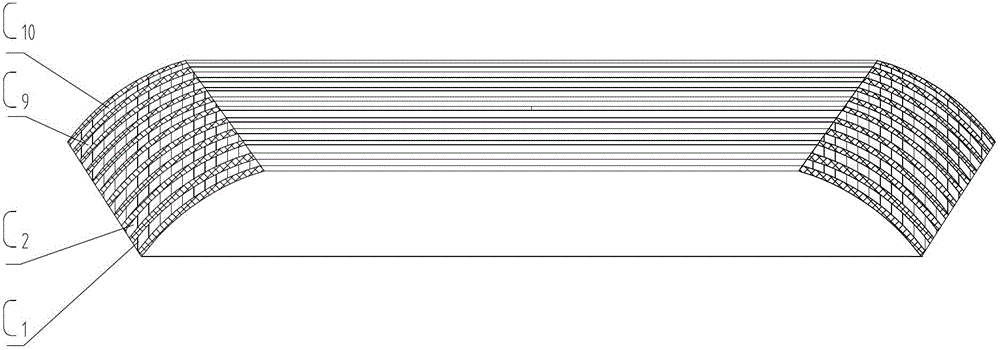

[0034] figure 1 The shown flexible joint assembly for the flexible nozzle of the solid rocket motor includes a front flange body A and a rear flange body D, and the elastic member group B and reinforcement are used between the front flange body A and the rear flange body D The component group C is connected, and the elastic component group B is composed of a matching 11-layer concentric spherical annular natural rubber compound rubber elastic sheet B 1 ~B 11 constituted, the thickness of each sheet is 1.3mm, such as figure 2 Shown; reinforcement group C is made of matching 10-layer concentric spherical annular high-strength steel rigid sheet C 1 ~C 10 Composition; the thickness of each sheet in reinforcement group C is 1.8mm, such as image 3 As shown, the 11-layer concentric spherical elastic sheet B 1 ~B 11 With 10 layers of concentric sphere ring-shaped rigid sheet C 1 ~C 10 It has an alternating spaced bonding structure, and is thermally vulcanized and bonded toge...

Embodiment 2

[0052] A flexible joint assembly for a flexible nozzle of a solid rocket motor, including a front flange body A and a rear flange body D, and an elastic member group B and a reinforcing member are passed between the front flange body A and the rear flange body D The group C is connected, and the elastic part group B is composed of 11 layers of concentric spherical ring-shaped natural rubber compound elastic sheet B that matches 1 ~B 11 The reinforcement group C is composed of 10 layers of concentric spherical annular high-strength steel rigid sheets C 1 ~C 10 Composition; the thickness of each thin sheet in the elastic member group B is 1.8mm; the thickness of each thin sheet in the reinforcing member group C is 2.0mm; the 11-layer concentric spherical annular elastic thin sheet B 1 ~B 11 With 10 layers of concentric sphere ring-shaped rigid sheet C 1 ~C 10 It has an alternating spaced bonding structure and is thermally vulcanized and bonded with the rear flange body D to...

Embodiment 3

[0070] A flexible joint assembly for a flexible nozzle of a solid rocket motor, including a front flange body A and a rear flange body D, and an elastic member group B and a reinforcing member are passed between the front flange body A and the rear flange body D The group C is connected, and the elastic part group B is composed of 9 layers of concentric spherical ring-shaped silicone rubber compound elastic sheets B that match 1 ~B 9 Composition, the reinforcement group C is made of matching 8-layer concentric spherical annular titanium alloy steel rigid sheet C 1 ~C 8 Composition; the thickness of each sheet in the elastic member group B is 2.0mm, the thickness of each sheet in the reinforcing member group C is 2.5mm, and the 9-layer concentric spherical annular elastic sheet B 1 ~B 9 With 8 layers of concentric sphere annular rigid sheet C 1 ~C 8 It has an alternating spaced bonding structure, and is thermally vulcanized and bonded with the rear flange body D to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com