Lead core rubber support composited by high-strength steel fibers and fine steel wire meshes

A technology of rubber bearings and lead rubber, which is applied to bridge parts, bridges, building components, etc., can solve problems such as insufficient shearing capacity, and achieve reliable overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

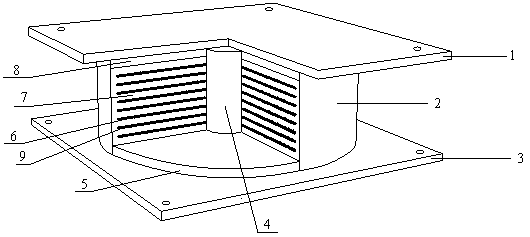

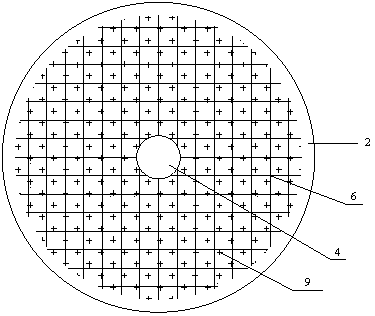

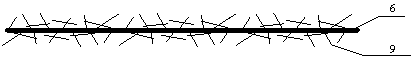

[0027] Embodiment 1: A high-strength steel fiber fine-dense steel wire mesh composite lead-core rubber bearing, consisting of an upper connecting steel plate 1, an upper sealing plate 8, an inner rubber layer 7, a high-strength fine-dense steel wire mesh layer 6, steel fibers 9, lead cores 4, The rubber protective layer 2, the lower sealing plate 5, and the lower connecting steel plate 3 are composed. The high-strength fine steel wire mesh layer 6 reserves lead core pressing holes according to the design position of the lead core, and the high-strength steel wire at the opening position is used as a hook, and steel fibers with random distribution are mixed on the steel wire mesh and the lower sides, and then combined with The rubber layer is fully bonded and vulcanized, pressed into the lead core 4, and the external vulcanized rubber protective layer 2 forms a lead core rubber pad; the upper sealing plate 8 and the lower sealing plate 5 are bonded to the upper and lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com