Compact composite light internal and external wall plate

A lightweight, wallboard technology, applied in building components, sustainable waste treatment, solid waste management, etc., can solve the problems of limited surface decoration, high price, etc., achieve strong resistance to bending and pressure, low cost, and a wide range of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

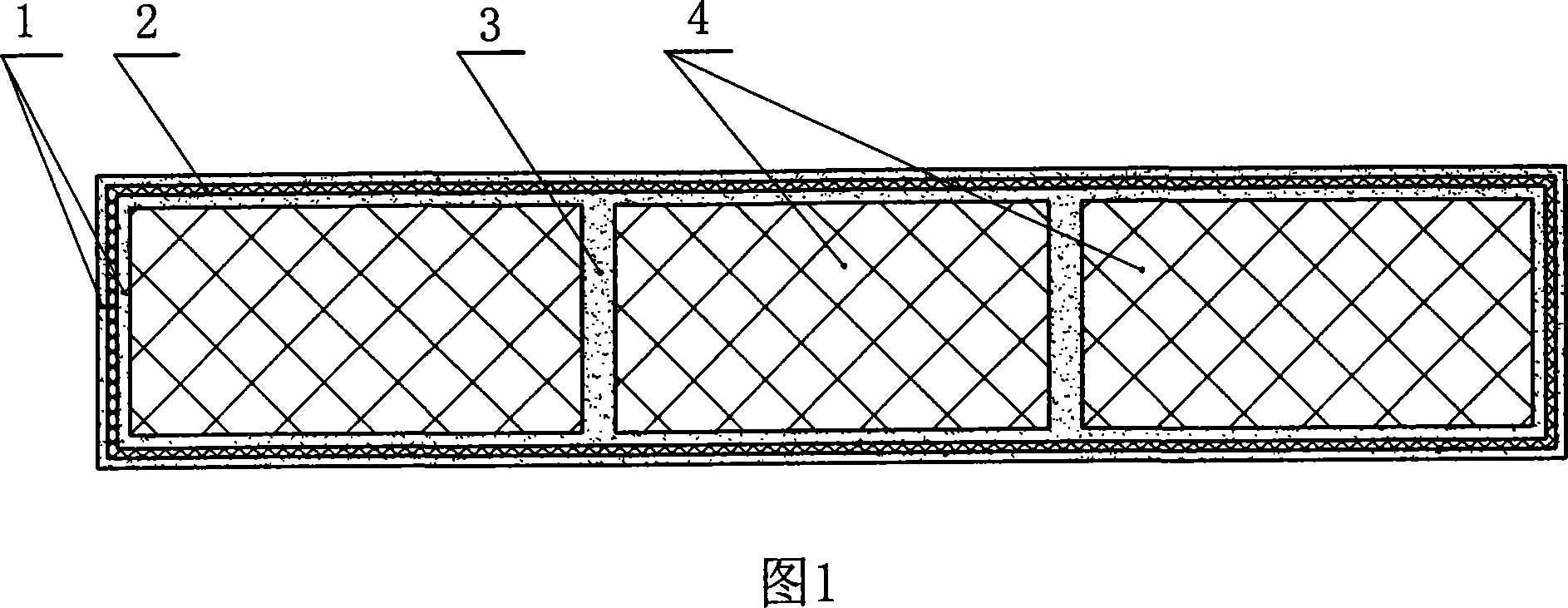

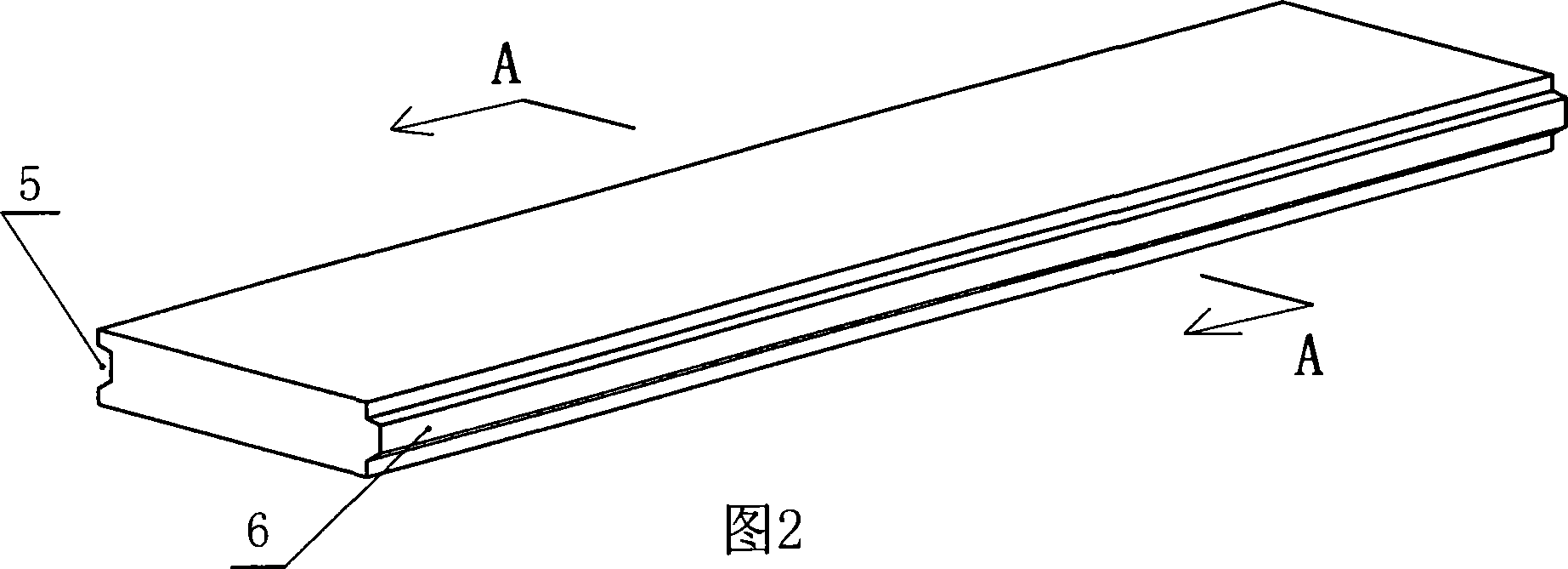

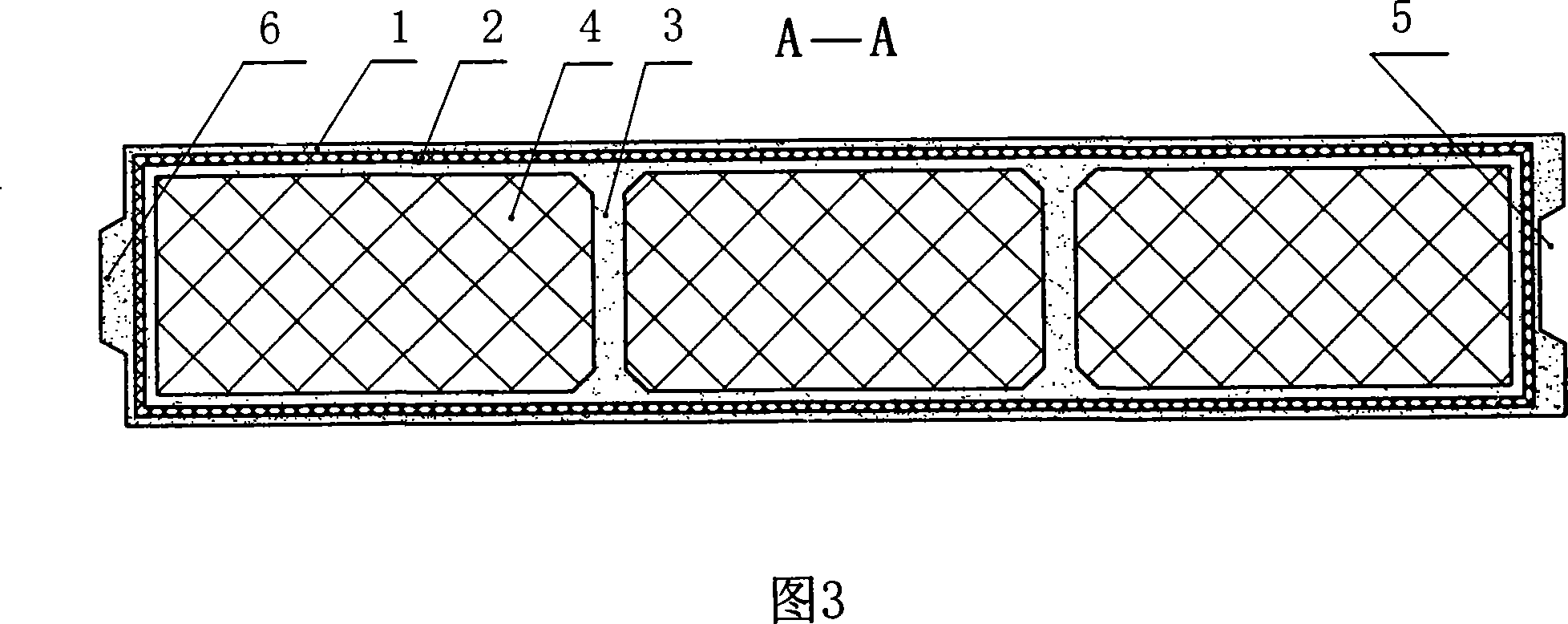

[0038] Embodiment 1 (foamed plastics layer 4 is the integral highly foamed polystyrene foam material board):

[0039] Present embodiment 1 is made by the raw material ratio of following weight parts (best embodiment):

[0040] 100 parts of rapid-hardening and early-strength sulfoaluminate cement or iron-aluminate cement;

[0041] 30 parts of fly ash;

[0042] 8 parts of 107 or 801 glue for construction; the use of construction glue can increase the compactness of the board, achieve waterproof effect, and work together with the foaming agent to easily form bubbles, reduce the weight of the product, play the role of shock absorption and increase flexibility.

[0043] 0.2 parts of foaming agent; the foaming agent can be selected from commercially available rosin foaming agent, and can also be made according to conventional methods: such as boiling with rosin, hide glue or bone glue, NaOH or KOH.

[0044] Plastic-coated fiberglass mesh;

[0045] Highly expanded polystyrene foam...

Embodiment 2

[0051] Embodiment 2 (foamed plastics layer 4 is made by polystyrene foam particle):

[0052] Present embodiment 2 is made by the raw material ratio of following parts by weight:

[0053] 100 parts of rapid-hardening and early-strength sulfoaluminate cement or iron-aluminate cement;

[0054] 30 parts of fly ash;

[0055] 8 parts of 107 or 801 glue for construction;

[0056] 0.2 parts of foaming agent; the foaming agent can be selected from commercially available rosin foaming agent, and can also be made according to conventional methods: such as boiling with rosin, hide glue or bone glue, NaOH or KOH.

[0057] Plastic-coated fiberglass mesh;

[0058] Styrofoam pellets.

[0059] The steps of making the board are as follows:

[0060] (1) According to the above proportions by weight, mix rapid-hardening and early-strength sulfoaluminate cement or iron-aluminate cement, fly ash, 107 or 801 glue for construction with water and mix and stir evenly to make a slurry.

[0061] (2)...

Embodiment 3

[0064] Embodiment 3 (foamed plastics layer 4 is the integral highly foamed polystyrene foam material board):

[0065] Present embodiment 3 is made by the raw material ratio of following parts by weight:

[0066] 100 parts of rapid-hardening and early-strength sulfoaluminate cement or iron-aluminate cement;

[0067] 35 parts of fly ash;

[0068] 10 parts of 107 or 801 glue for construction;

[0069] 0.4 parts of foaming agent;

[0070] Plastic-coated fiberglass mesh;

[0071] Highly expanded polystyrene foam sheet with through-holes;

[0072] Preparation method is as embodiment 1. Compared with Embodiment 1, Embodiment 3 is lighter in weight, slightly higher in cost, and weaker in strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com