Method for preparing multilayer low-temperature cofired ceramics integrated liquid cooling circulation channel

A low-temperature co-fired ceramic and circulating channel technology, which can be used in semiconductor/solid-state device manufacturing, antenna support/installation devices, electrical components, etc., and can solve problems such as no bulging and no delamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described step by step below in conjunction with the accompanying drawings and examples.

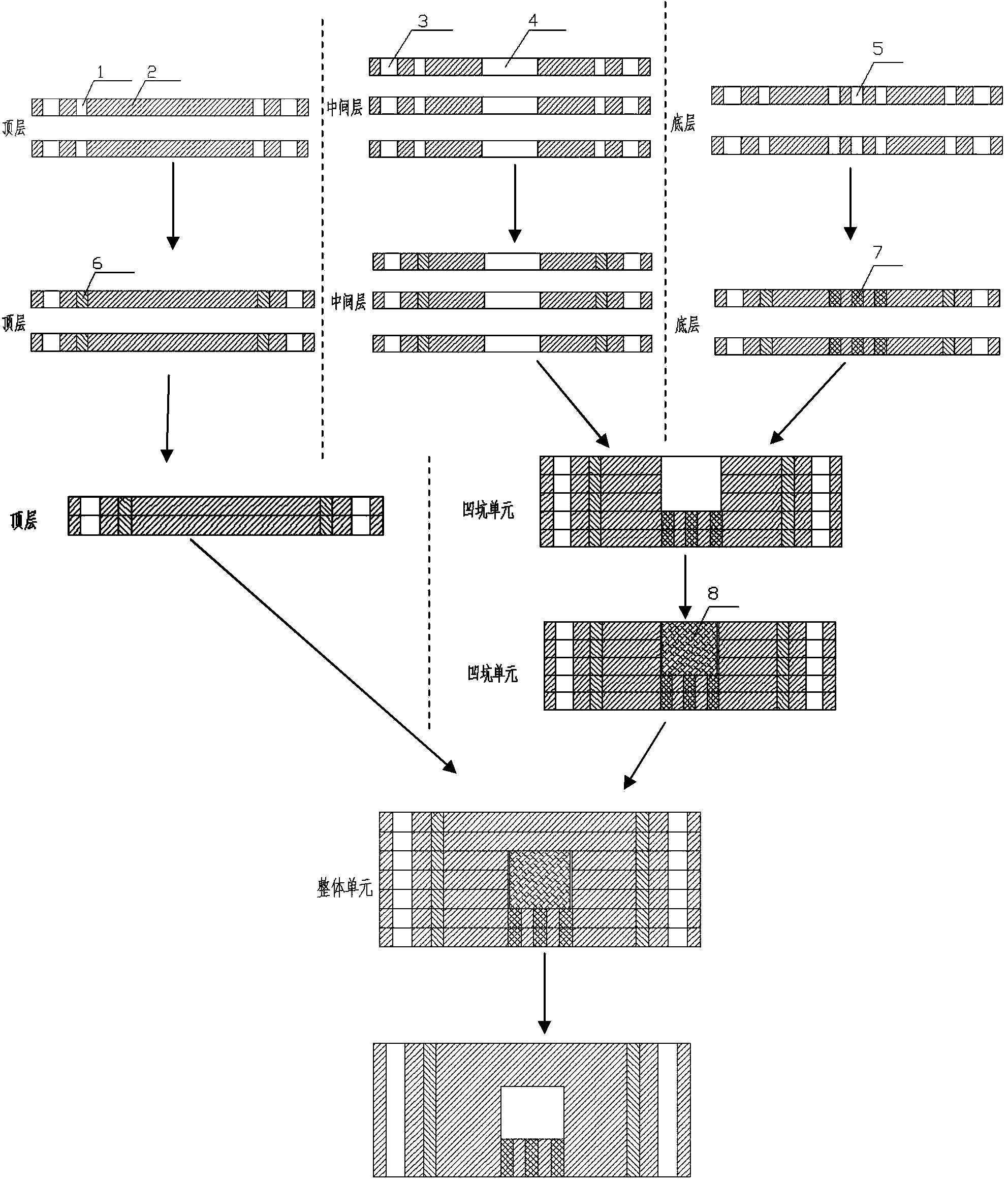

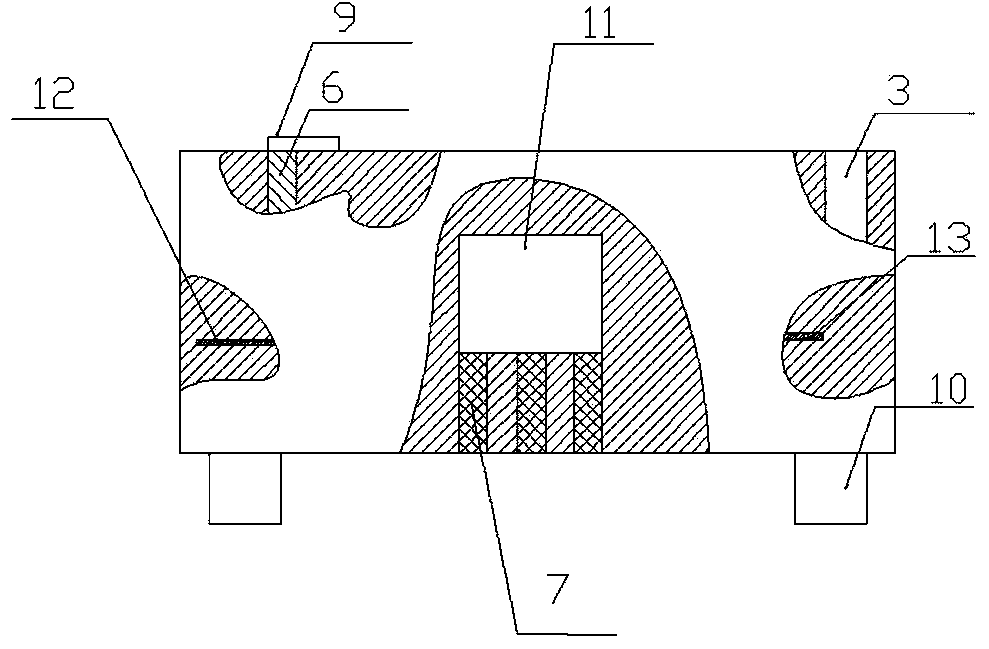

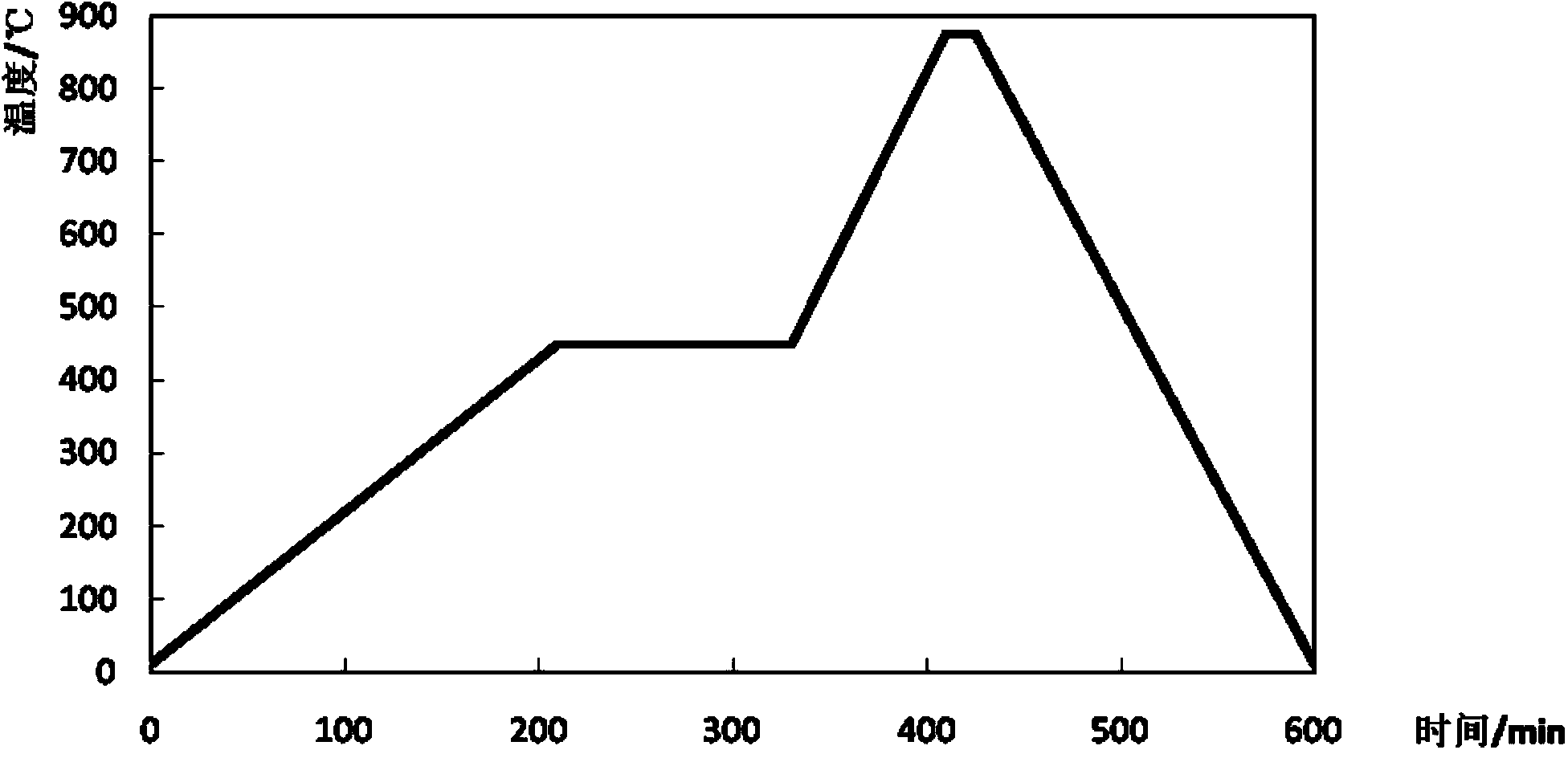

[0017] refer to figure 1 . According to the present invention, after the production steps are determined, the determination of the process parameters is the key to ensure the production of the closed cavity, and the main influencing factors are: alignment accuracy, lamination pressure, lamination temperature, filling density, and sintering temperature. The low-temperature sintered ceramic powder is made into a green tape with precise thickness and density, and the required circuit patterns and wiring patterns are produced on the green tape by drilling, microporous grouting, and precision conductor paste printing. Passive components, such as low-capacity capacitors, resistors, filters, impedance converters, couplers, etc., are embedded in multilayer ceramic substrates, and then stacked together and sintered at 900 ° C to make high-density non-interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com