Vacuum pneumatic ink containers

An ink and vacuum technology, applied in the direction of packaging under vacuum/special atmosphere, packaging objects under special gas conditions, special packaging objects, etc., can solve the problems of inconvenient production operation and transportation, small outer diameter of sealing cover, incomplete exhaust, etc. problems, to achieve the effect of convenient transportation and filling operations, simple ink extraction operations, and clean and thorough exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

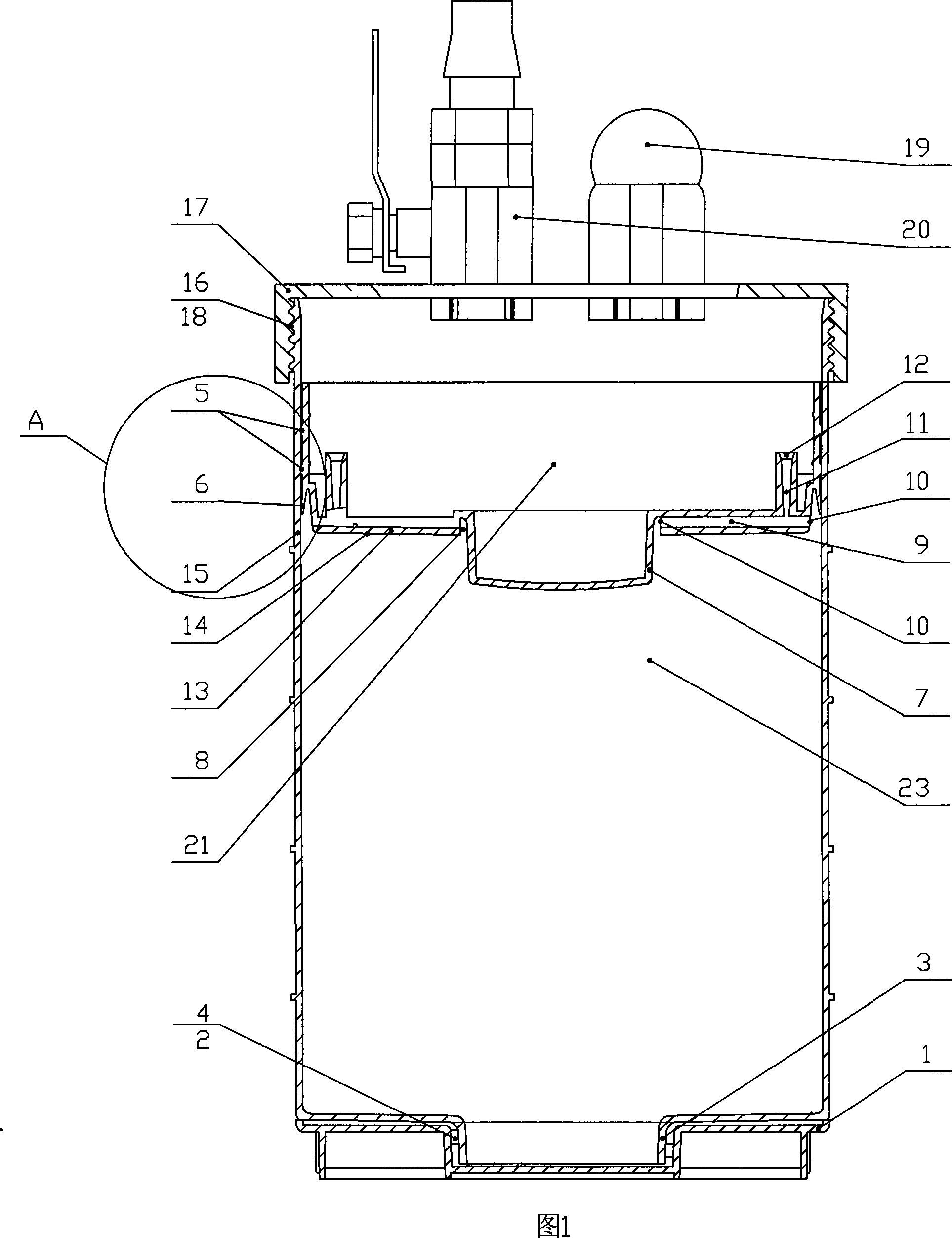

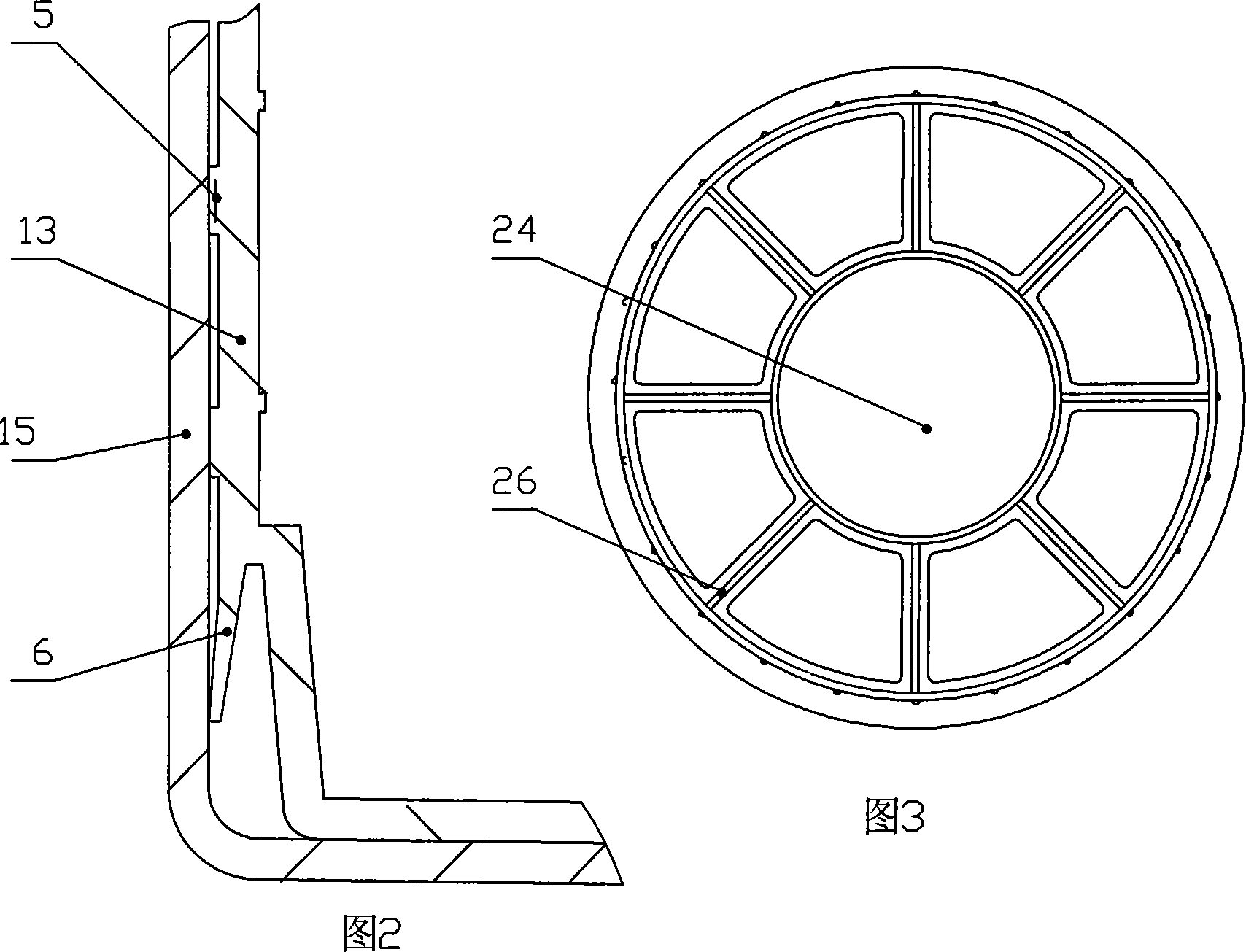

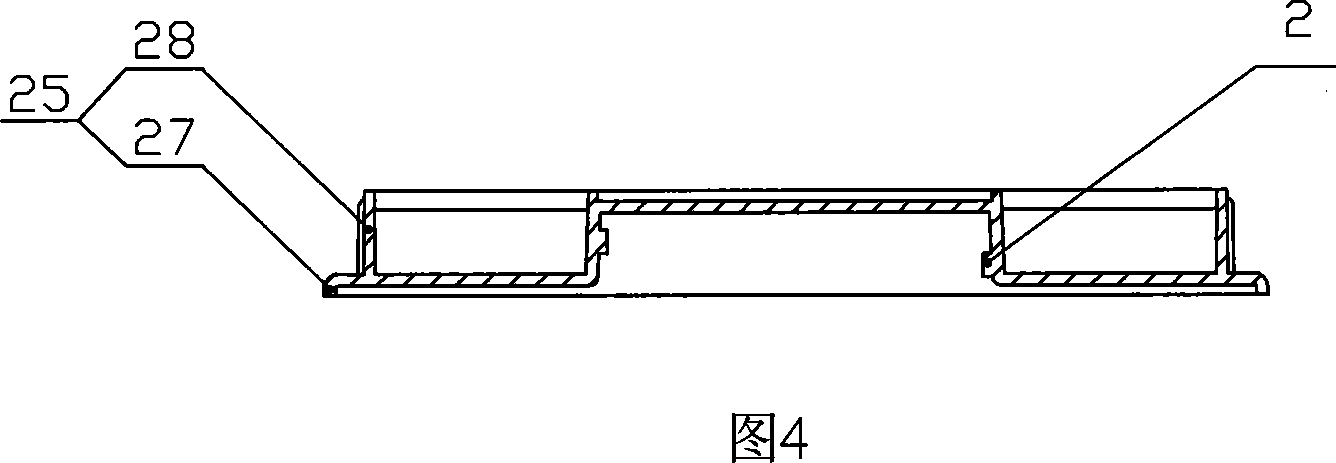

[0019] The specific implementation of the vacuum pneumatic ink container will be further described in detail below in conjunction with the accompanying drawings.

[0020] Referring to Figures 1 to 8, the vacuum pneumatic ink container of the present invention includes a cylinder body 15 and a hollow piston 13 located in the cylinder body 15, the ink is vacuum-packed in the front cavity defined by the cylinder body 15 and the hollow piston 13, and the rear The end is closed by a hollow piston 13. The front end of cylinder body 15 is provided with ink outlet 3, and end cap 1 is housed on it. The front end surface of the hollow piston 13 is provided with a boss 7 matched with the inner hole of the ink outlet 3 . A connecting thread 18 is provided on the side of the outer wall of the rear end of the cylindrical body 15, on which an inflatable sealing cover 17 is housed. When the printing machine needs to add ink, the pressure air enters the cylinder body 15 and the rear cavity (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com