The invention discloses an optical screen structure of an ultrathin laser television

A technology of laser TV and screen structure, applied in the direction of TV, color TV, color TV components, etc., can solve the problems of thick screen structure, very high requirements, increase the thickness and strength of structural parts, etc., to reduce the thickness of the screen, guarantee The effect of flatness and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, a 100-inch ultra-thin laser TV screen will be used as a specific embodiment to illustrate the technical solution of the present invention.

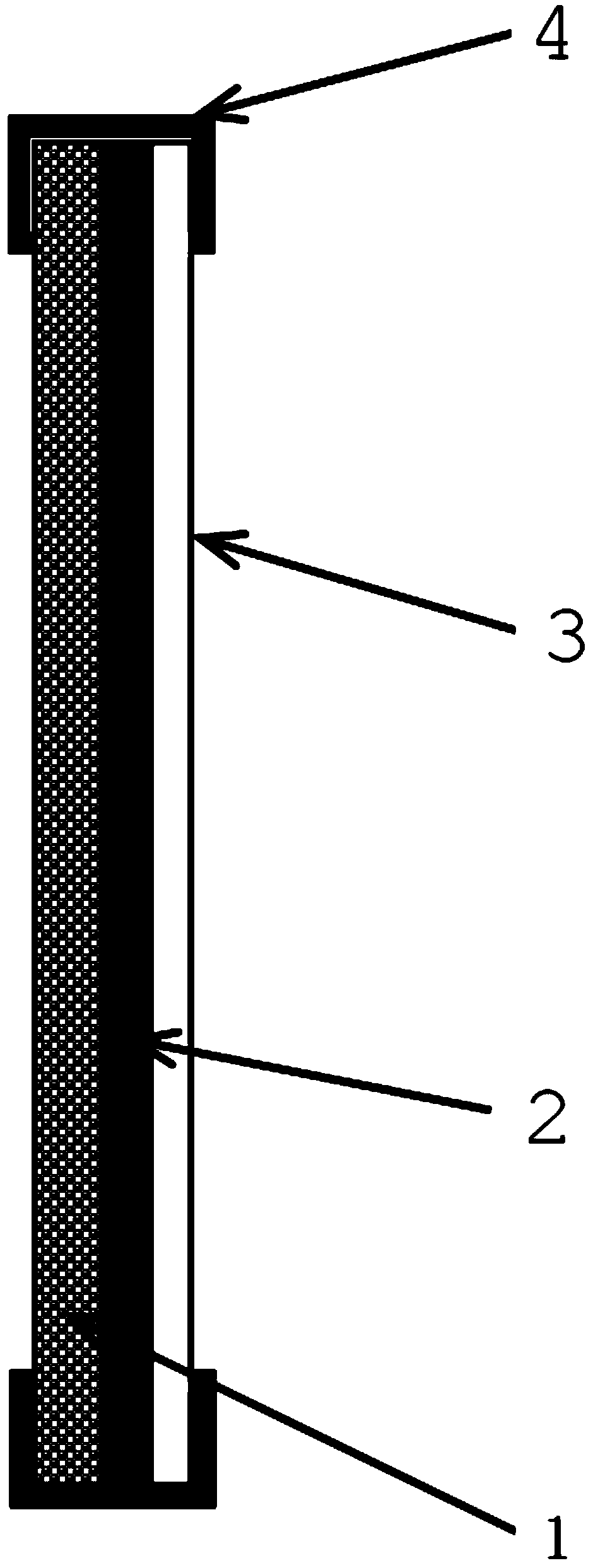

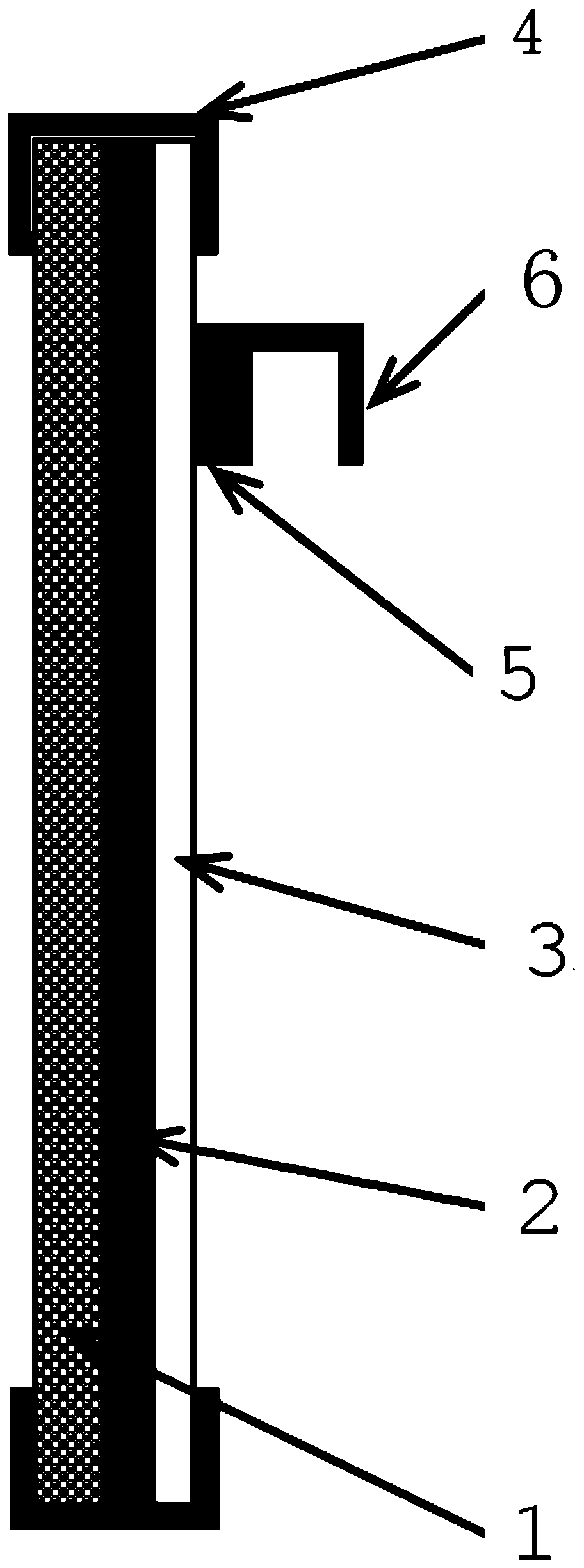

[0031] Such as figure 1 and image 3 As shown, an ultra-thin laser TV optical screen structure includes: a projection optical film 1, a support backplane 3, a decorative surface frame 4, a first adhesive 2, a second adhesive 5 and a hanger assembly 6, Wherein, the projection optical film 1 is bonded to the front of the support backplane 3 by the first adhesive 2, and the hanger assembly 6 is fixed on the back of the support backplane 3. In this embodiment, the hanger assembly 6 is specifically bonded by the second adhesive The adhesive 5 is bonded and fixed on the back of the support backboard 3 , in practice, it can also be fixed by means of riveting, screwing or the like.

[0032] The decorative surface frame 4 is wrapped around the end of the screen main body formed by the projection optical film 1, the fir...

Embodiment 2

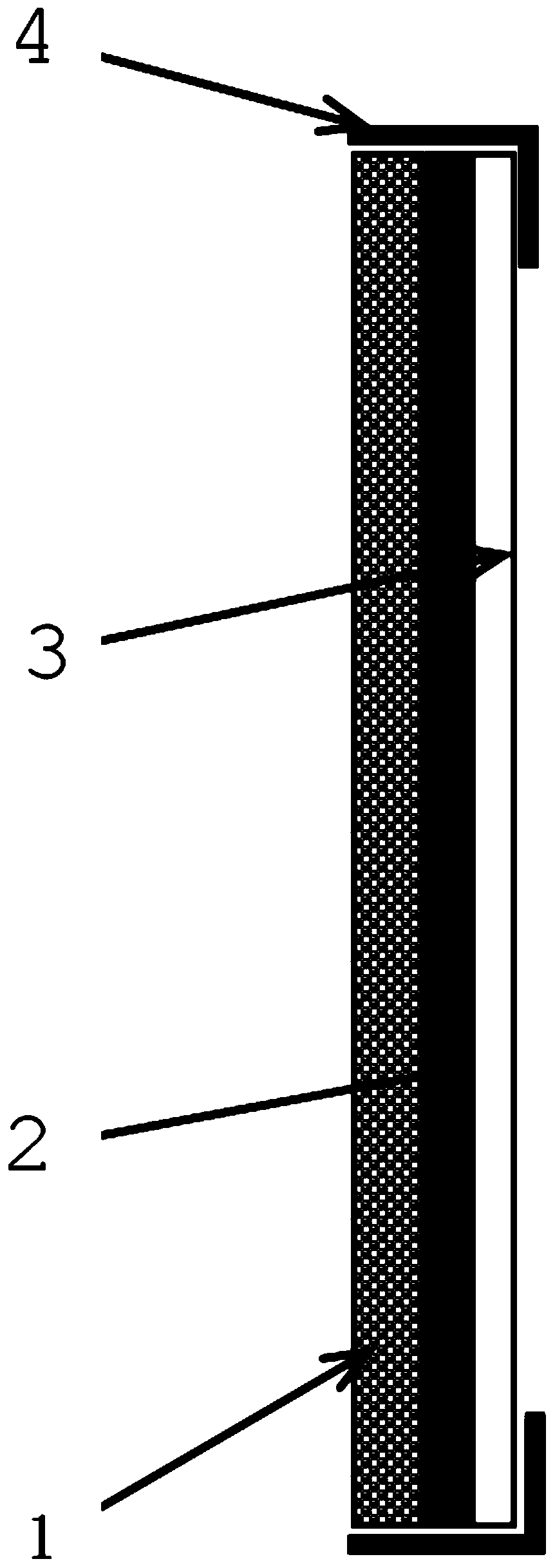

[0038] Such as figure 2 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the decorative surface frame 4 in this embodiment is L-shaped, and in this embodiment, two sets of hanger assemblies 6 are arranged on the back of the supporting backboard 3 In order to achieve a better installation and fixing effect.

Embodiment 3

[0040] Such as Figure 5 and Figure 6 As shown, the difference between the present embodiment and the second embodiment is that in the present embodiment, the hanger assembly 6 includes a soft magnet mounting frame (not shown in the figure) and a magnetic hanging frame 61, and the soft magnetic body mounting frame is compatible with the magnetic mounting frame. The hanger 61 is magnetically connected and fixed by riveting, screwing or bonding. The soft magnetic mounting frame is directly fixed on the screen mounting surface, and then the soft magnetic mounting frame and the magnetic hanging frame 61 are used to fix and support the ultra-thin screen. Laser TV optical screen structure.

[0041] In this embodiment, the support backboard 3 is made of non-ferrous or magnetic material, so the magnetic hanger 61 of the hanger assembly 6 is still glued and fixed on the back of the support backboard 3 by the second adhesive 5 .

[0042] In practice, the support backboard 3 can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com