Earth and garlic separating mechanism of garlic harvester

A separation mechanism and harvester technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of high requirements for clamping mechanisms, high labor intensity, and garlic drop, and achieve excellent radial bearing capacity. Ability, the effect of reducing garlic drop, reducing the probability of garlic dropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

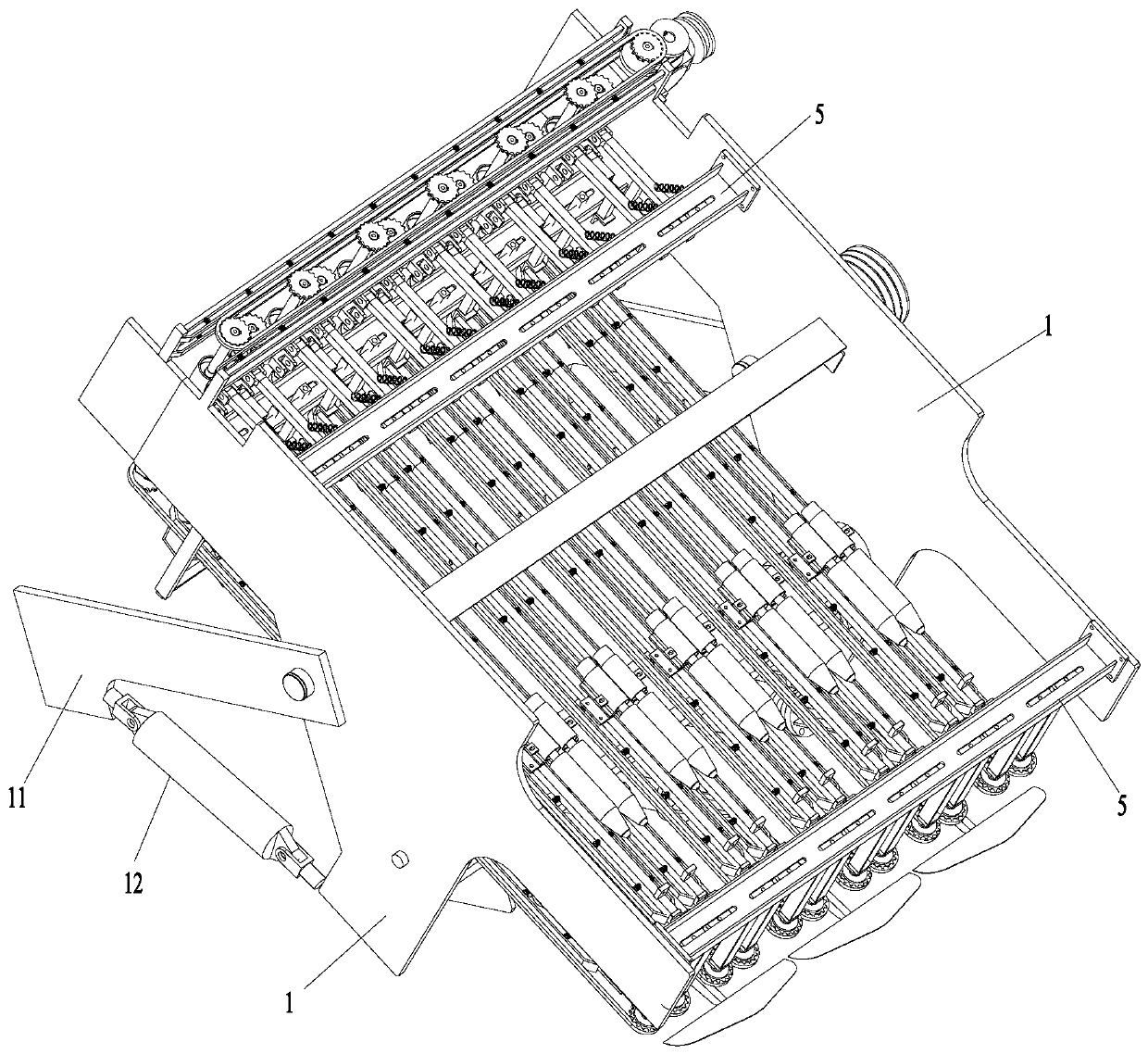

[0049] Such as figure 1 Shown, the present invention provides a kind of soil of garlic harvester, garlic separating mechanism, and this mechanism is installed on the tractor by two symmetrically arranged side plates 1 (as Figure 15 As shown), the side plate 1 is provided with a rotatable support arm 11, the support arm 11 is fixed on the tractor, and a drive cylinder 12 is arranged between the support arm 11 and the side plate 1, and the cylinder body and the extension end of the drive cylinder 12 are respectively connected with The support arm 11 is connected to the side plate 1 in rotation, and the expansion and contraction of the driving cylinder 12 realizes the rotation of the side plate 1 .

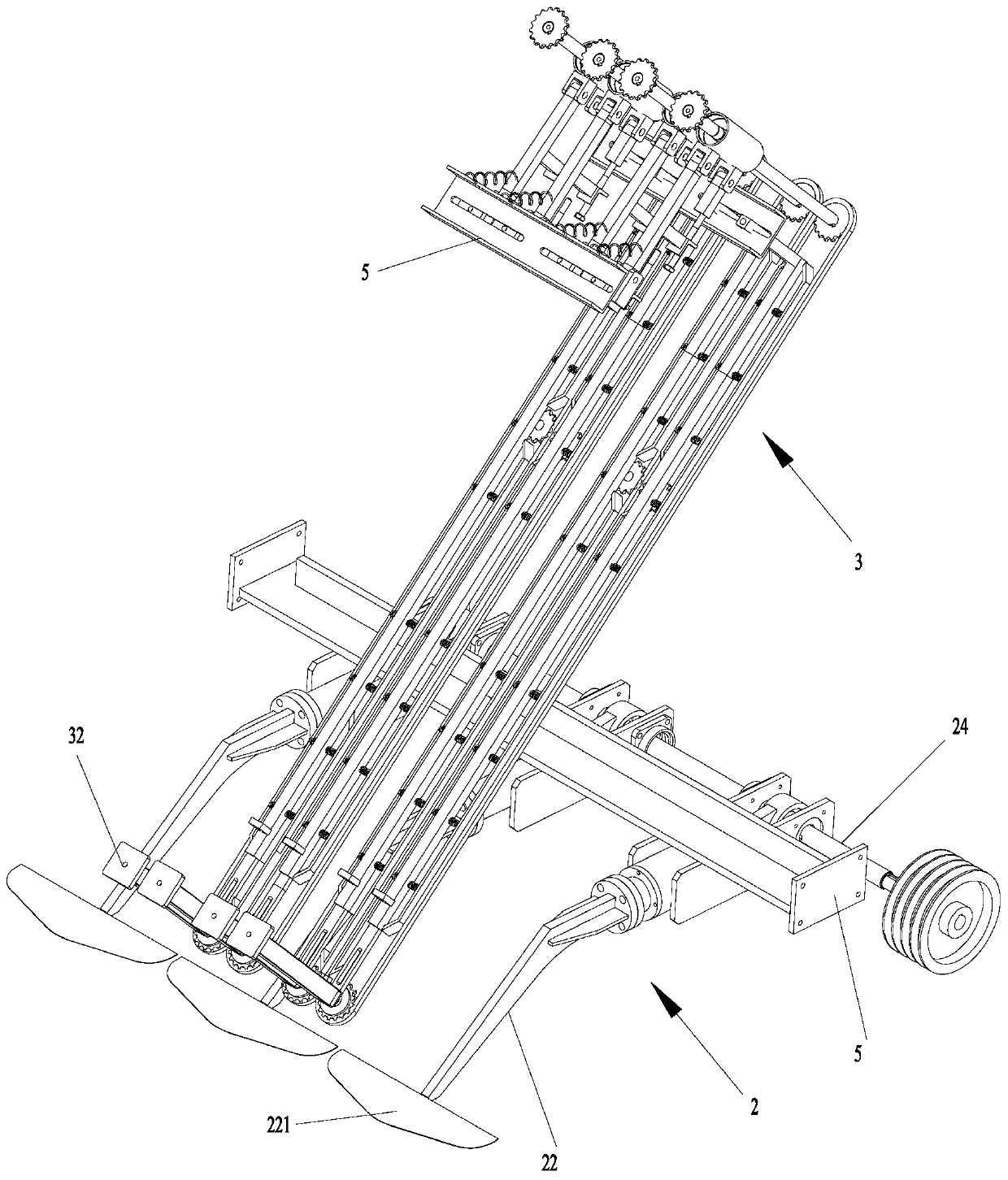

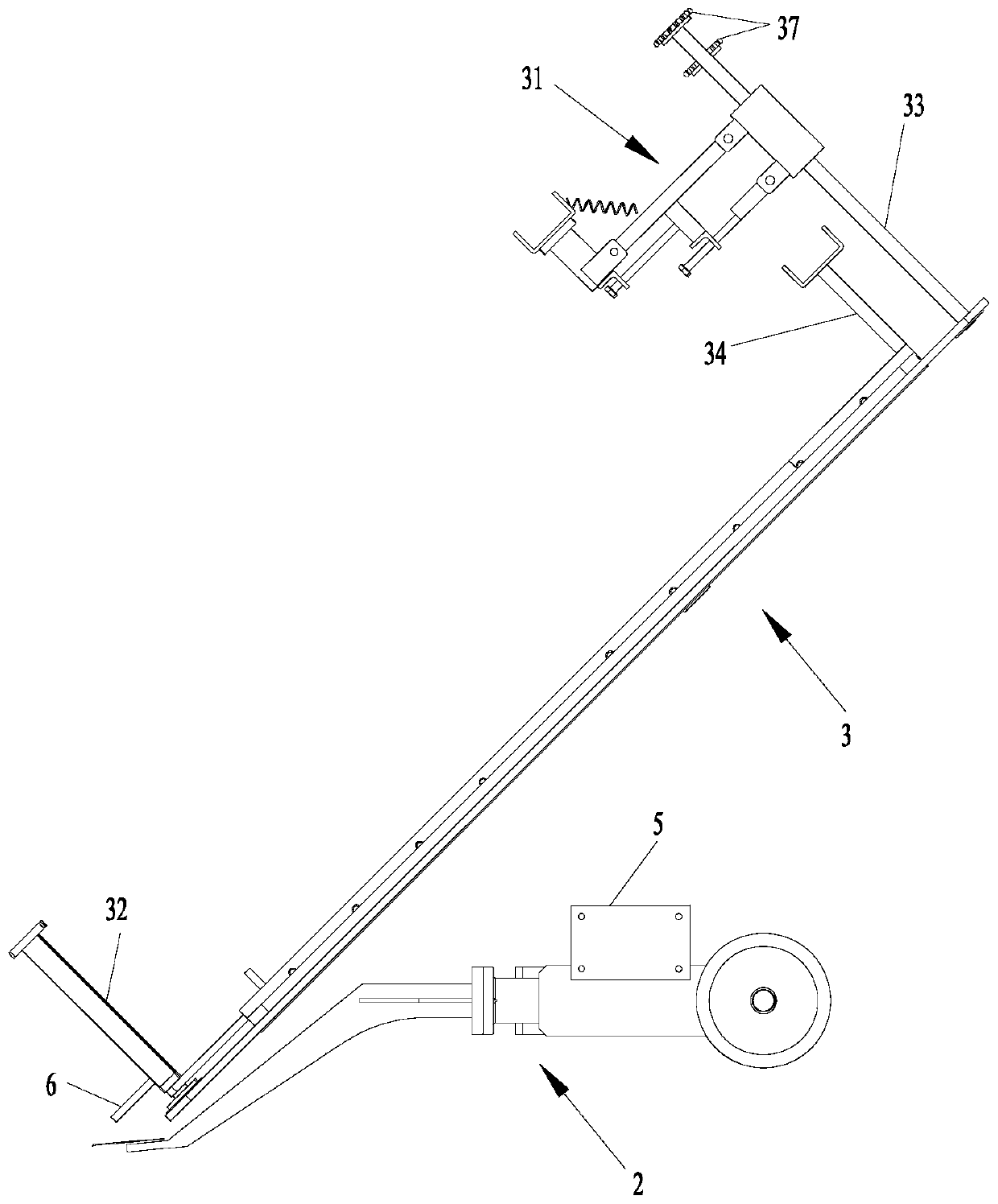

[0050] The mechanism includes a shovel unit 2, a chain hoist unit 3 and a drive unit, the shovel unit 2 is used to separate the garlic from the soil layer, and the chain hoist unit 3 is used to transfer the garlic to the collection box, which is located on the tractor. On the top, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com