Depth-limit digging mechanism of combined garlic harvester

A combined harvester and depth-limiting technology, which is applied to excavators, digging harvesters, harvesters, etc., can solve the problems of periodic resonance, unsupported cutting, and inability to cut residual film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

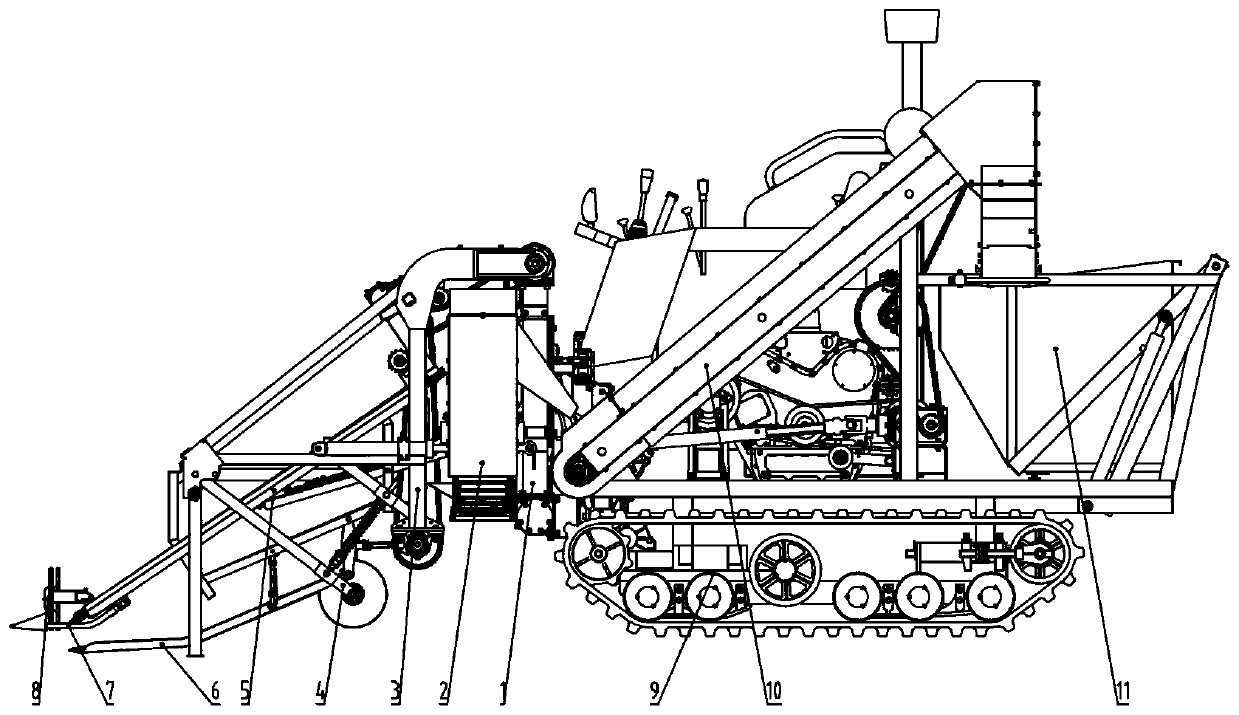

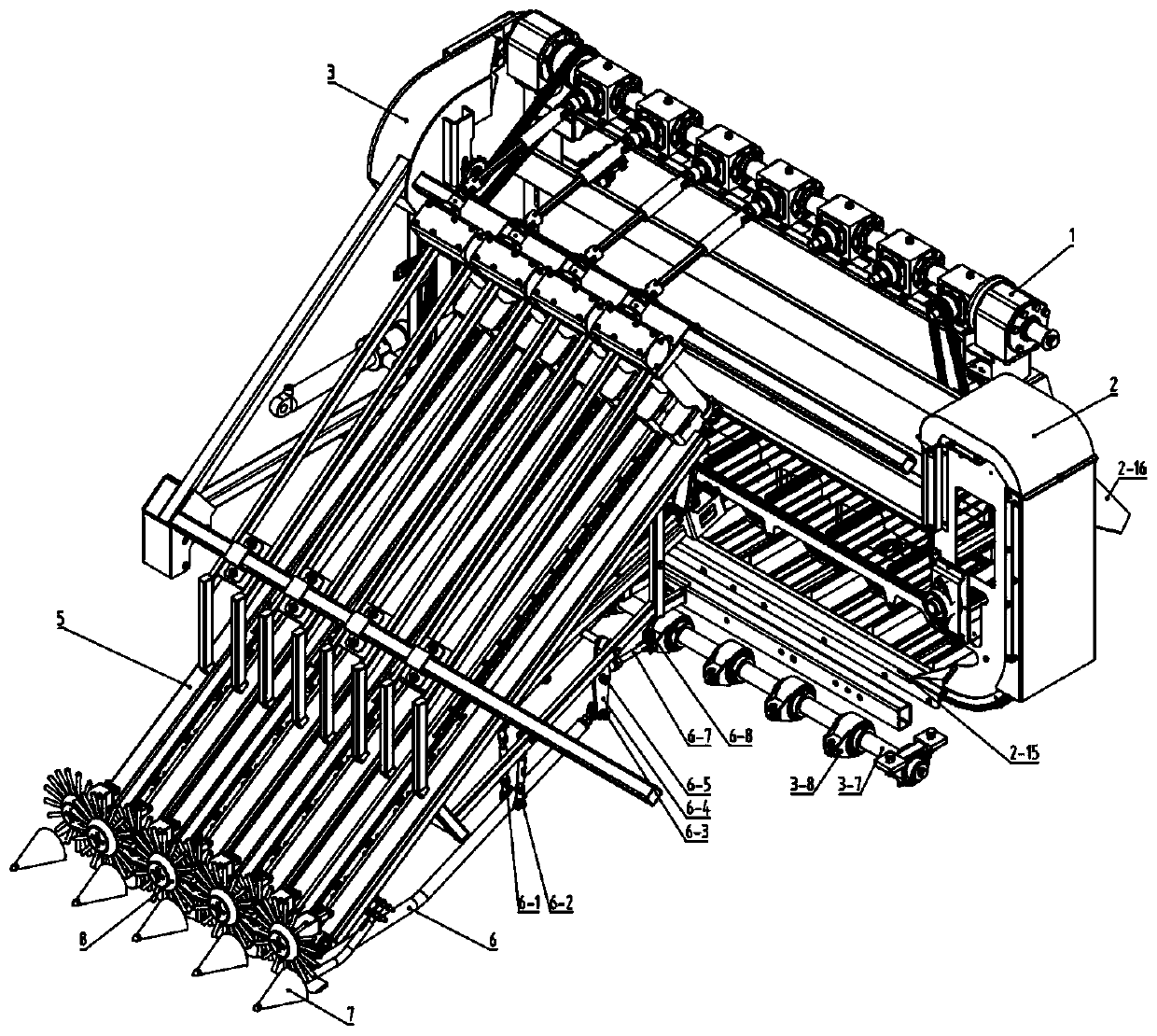

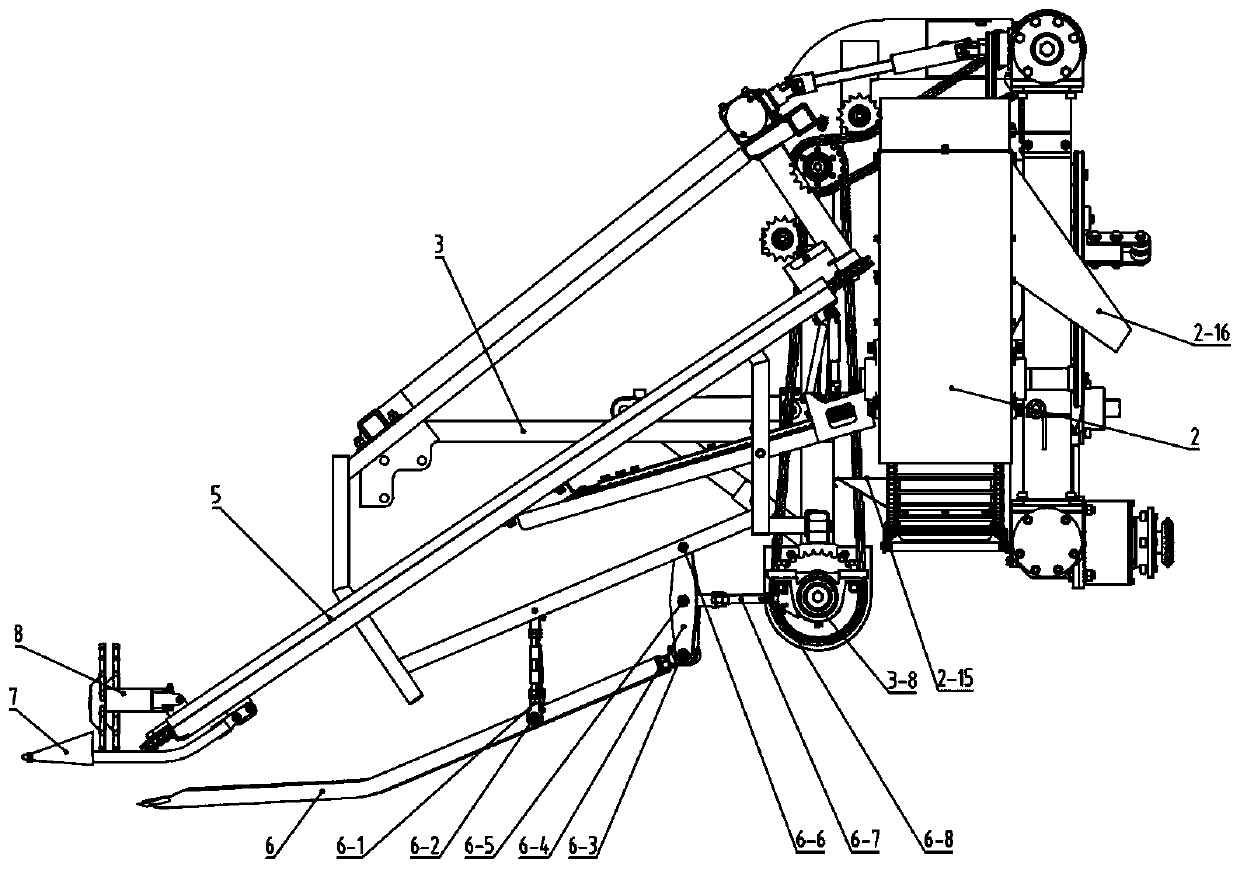

[0023] The depth-limiting excavation mechanism of this embodiment is installed on figure 1 Front end of a multi-row garlic combine harvester shown. The crawler-type walking chassis 9 of the combine harvester is equipped with garlic elevating soil clearing conveying device 10 and self-unloading fruit collection bin 11, and its front part is equipped with a harvesting platform that can float up and down through a harvesting platform mounting frame 1 that can rotate left and right. Frame 3 and the conveying bar chain device 2, 2-15, and 2-16 are respectively the collection hopper and the discharge chute of the device for collecting and arranging the garlic heads; A plurality of single-way headers 5, each single-way header 5 is equipped with a clamping conveyor chain along the conveying direction from low to high, and a forward-extending excavation shovel 6 is respectively installed below it, and a grain dividing device 7 and a hand-holding device are installed on the front end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com