Multi-stage drafting device and method for nylon 6 high-strength yarn

A drafting device and drafting technology, used in textiles and papermaking, can solve the problems of reduced elongation at break, short setting time, and reduced toughness, so as to improve the degree of fiber orientation and strength, avoid the reduction of fiber toughness, and prevent the effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

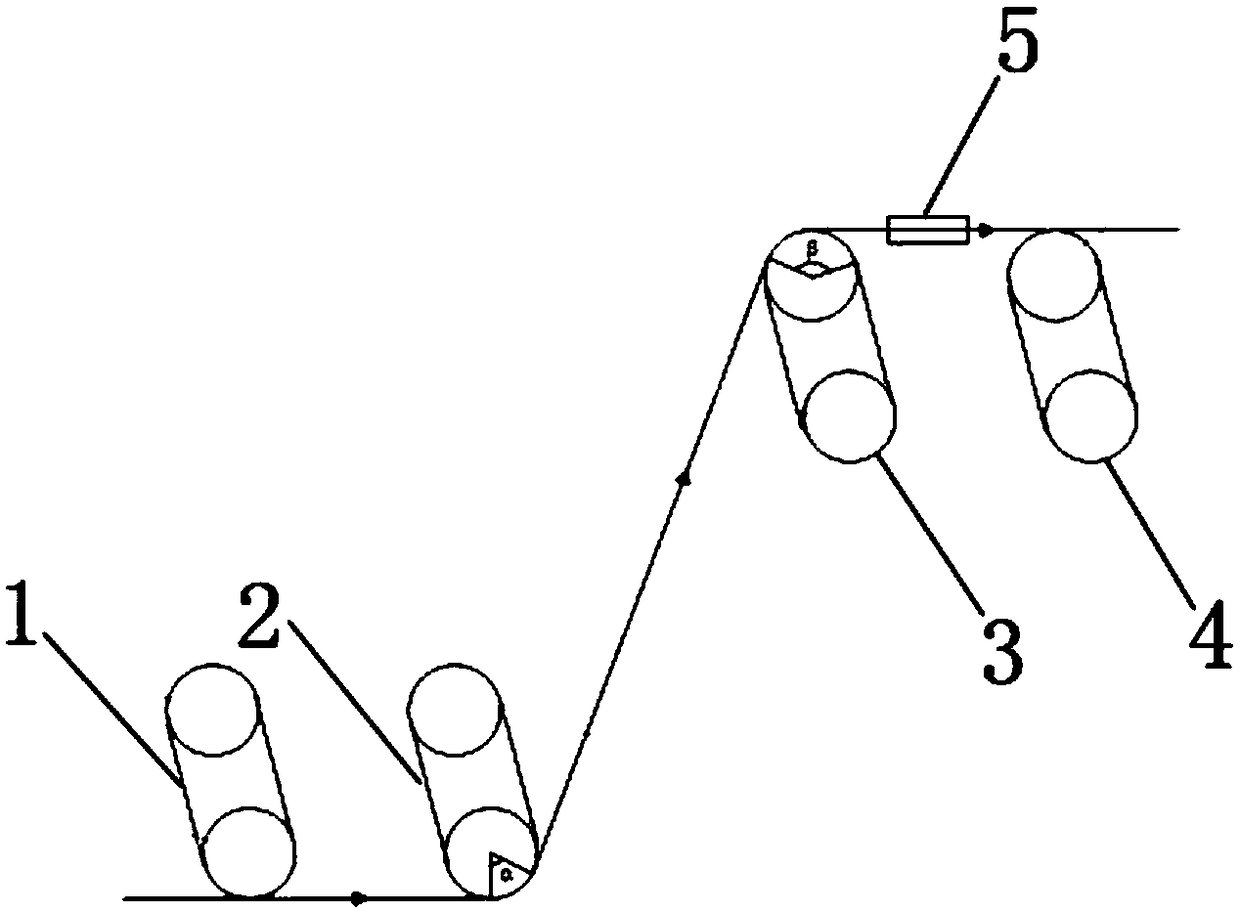

[0021] Nylon 6 slices with a viscosity of 2.4 are fed into the feeder and then melted and extruded through a twin-screw extruder. The temperature of the first zone of the twin-screw extruder is 225°C, the temperature of the second zone is 240°C, and the temperature of the third zone is 245°C. , the temperature in the fourth zone is 250°C, the temperature of the machine head is 255°C, and the polyamide 6 melt passes through the double-side air cooling with a temperature of 20°C after spinning from the spinneret, a wind speed of 0.5m / s, and a relative humidity of 75%. , The spinning speed is 4500m / min. The spinning that is spun out is carried out drafting three times, and the drafting multiple of one-stage drafting is 2.60, and the drafting multiple of secondary drafting is 1.80, and the drafting multiple of three-stage drafting is 1.05, and the first drafting hot roll The temperature of 1 is 50 ℃, the temperature of the second drafting hot roller 2 is 100 ℃, the temperature of ...

Embodiment 2

[0023] Nylon 6 slices with a viscosity of 2.4 are fed into the feeder and then melted and extruded through a twin-screw extruder. The temperature of the first zone of the twin-screw extruder is 225°C, the temperature of the second zone is 240°C, and the temperature of the third zone is 245°C. , the temperature in the fourth zone is 250°C, the temperature of the machine head is 255°C, and the polyamide 6 melt passes through the double-side air cooling with a temperature of 20°C after spinning from the spinneret, a wind speed of 0.5m / s, and a relative humidity of 75%. , The spinning speed is 4500m / min. The silk that is spun out is carried out drafting three times, and the drafting multiple of first-stage drafting is 2.60, and the drafting multiple of secondary drafting is 1.80, and the drafting multiple of three-stage drafting is 1.05, and the first drafting hot roller 1 The temperature is 55°C, the temperature of the second drafting hot roll 2 is 105°C, the temperature of the t...

Embodiment 3

[0025] Nylon 6 slices with a viscosity of 2.4 are fed into the feeder and then melted and extruded through a twin-screw extruder. The temperature of the first zone of the twin-screw extruder is 225°C, the temperature of the second zone is 240°C, and the temperature of the third zone is 245°C. , the temperature in the fourth zone is 250°C, the temperature of the machine head is 255°C, and the polyamide 6 melt passes through the double-side air cooling with a temperature of 20°C after spinning from the spinneret, a wind speed of 0.5m / s, and a relative humidity of 75%. , The spinning speed is 4500m / min. The spun silk is drawn three times, the draft multiple of the primary draft is 2.6, the draft multiple of the secondary draft is 1.80, the draft multiple of the third draft is 1.05, and the first draft hot roller 1 The temperature of the hot plate is 70°C, the temperature of the second drafting hot roller 2 is 120°C, the temperature of the third drafting hot roller 3 is 178°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wrap angle | aaaaa | aaaaa |

| Wrap angle | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com