Non-leg plastic chair injection mold with sliding block loose-core mechanism

A slider core-pulling and injection molding technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problem that the precision of the socket leg socket hole cannot meet the socket requirements, and the core-pulling mechanism cannot pull the core at the same time. Problems such as uneven force on the chair surface can achieve the effects of reducing energy consumption, high degree of automation, and accurate control of core-pulling and reset actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

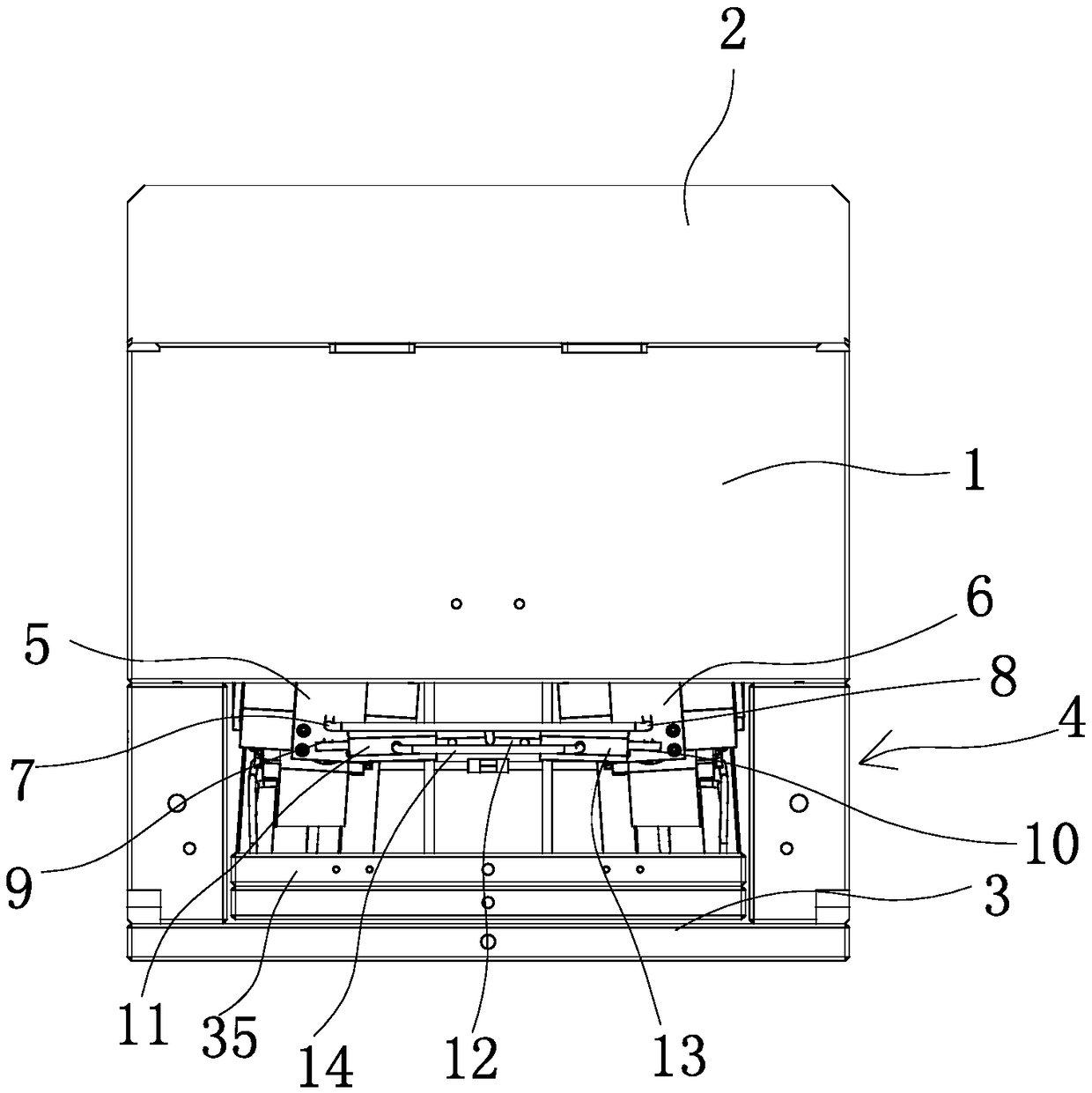

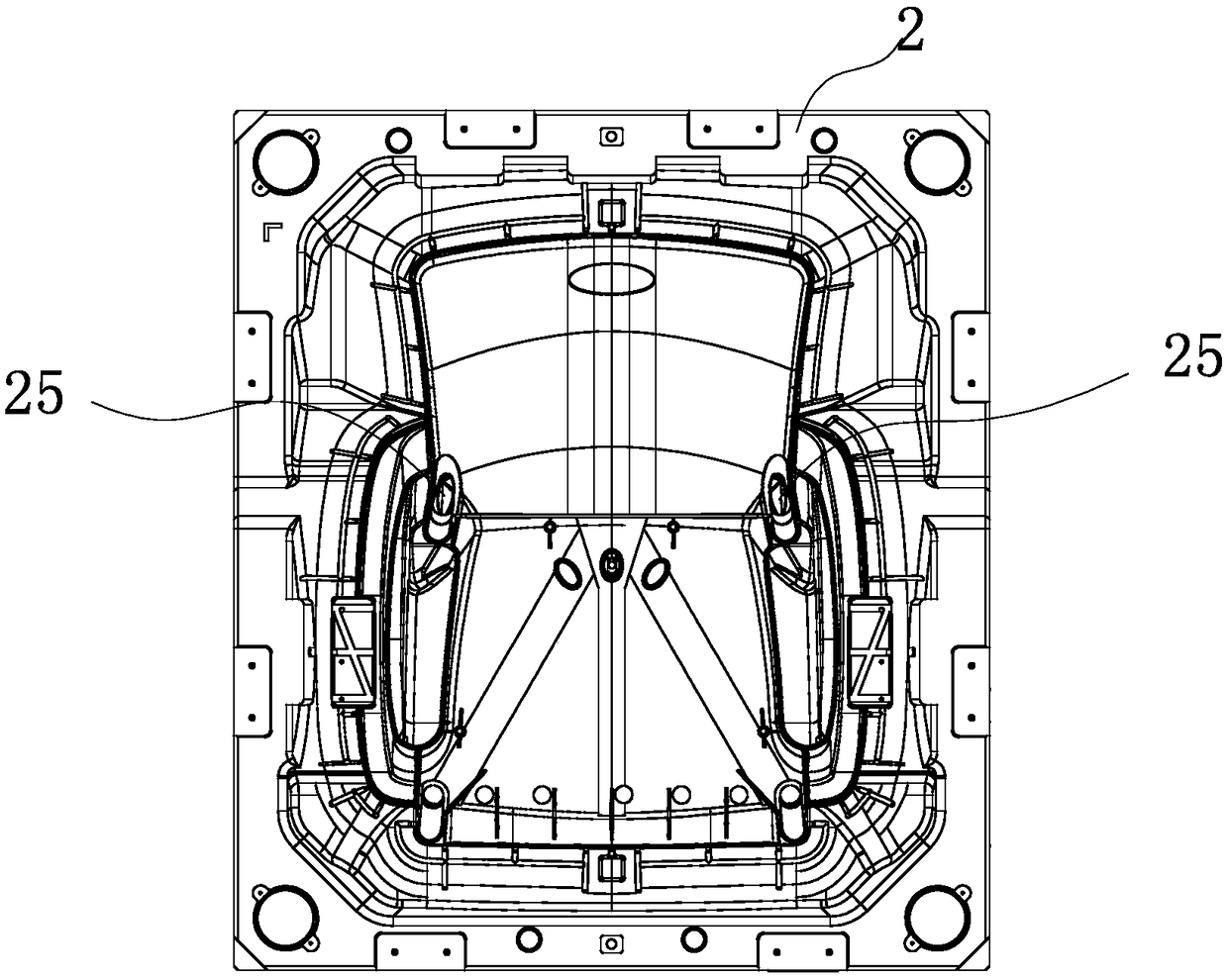

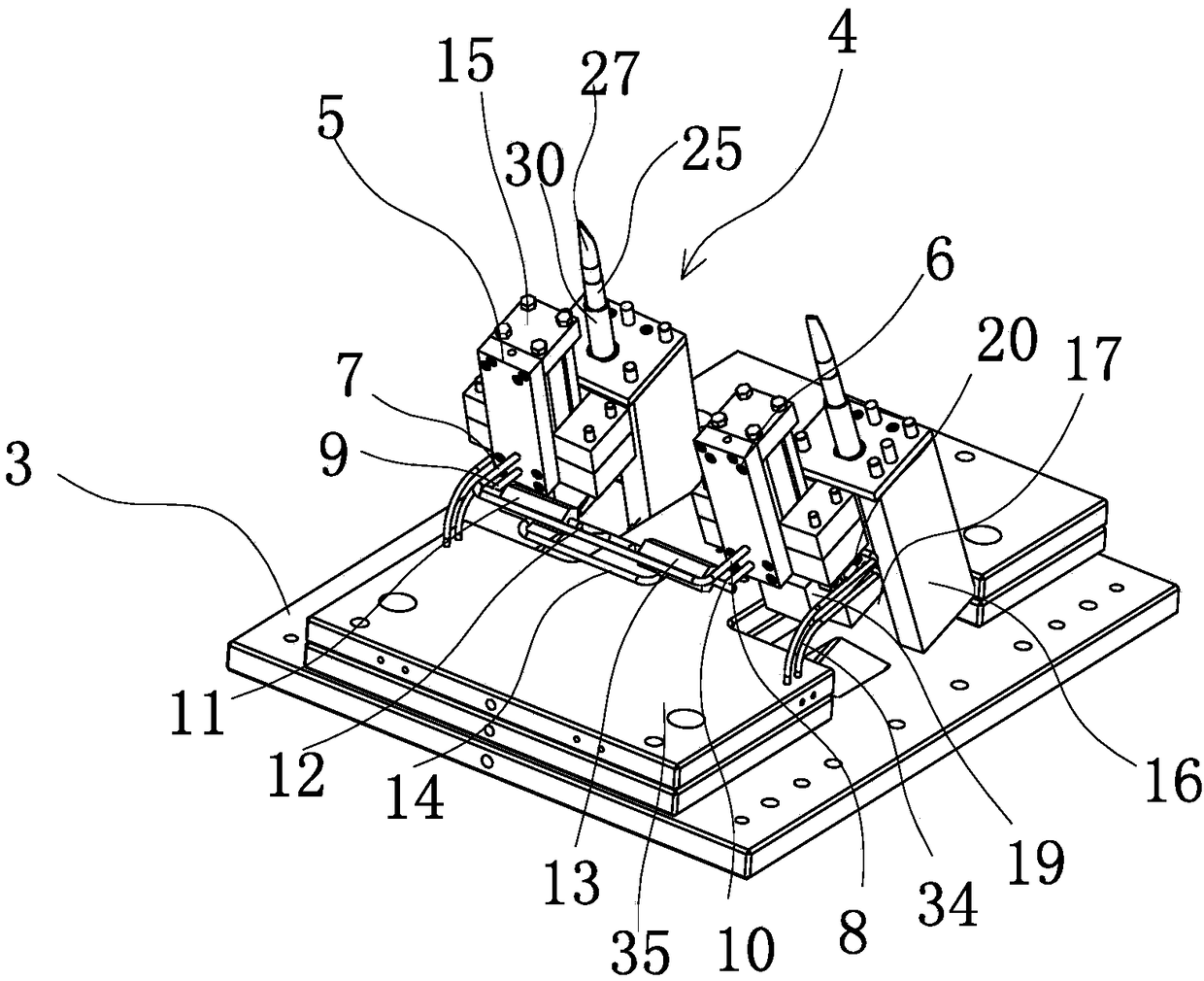

[0028] according to Figure 1-3 As shown, the injection mold for a legless plastic chair with a slider core-pulling mechanism includes a movable template 1, a fixed template 2 and a movable mold backing plate 3, and two chair leg insertion holes are arranged below the movable template 1. Core structure 4, the core-pulling structure 4 is provided with a first oil distribution plate 5 and a second oil distribution plate 6 on the two chair leg insertion holes, and the first oil distribution plate 5 is provided with a first oil distribution channel 7 and the second oil distribution channel 8, the second oil distribution plate 6 is provided with a third oil distribution channel 9 and a fourth oil distribution channel 10, the first oil distribution channel 7 and the third oil distribution channel 9 The second oil distribution channel 8 is connected to the fourth oil distribution channel 10 .

[0029] After the injection molding of the legless chair is completed, the core-pulling st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com