Anti-cutting glove and packaging method thereof

A packaging method and anti-cutting technology, applied in the field of labor protection gloves, can solve the problems of complicated process, low processing efficiency, unsuitable for mass production, etc., and achieve the effect of simple process operation, good air permeability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

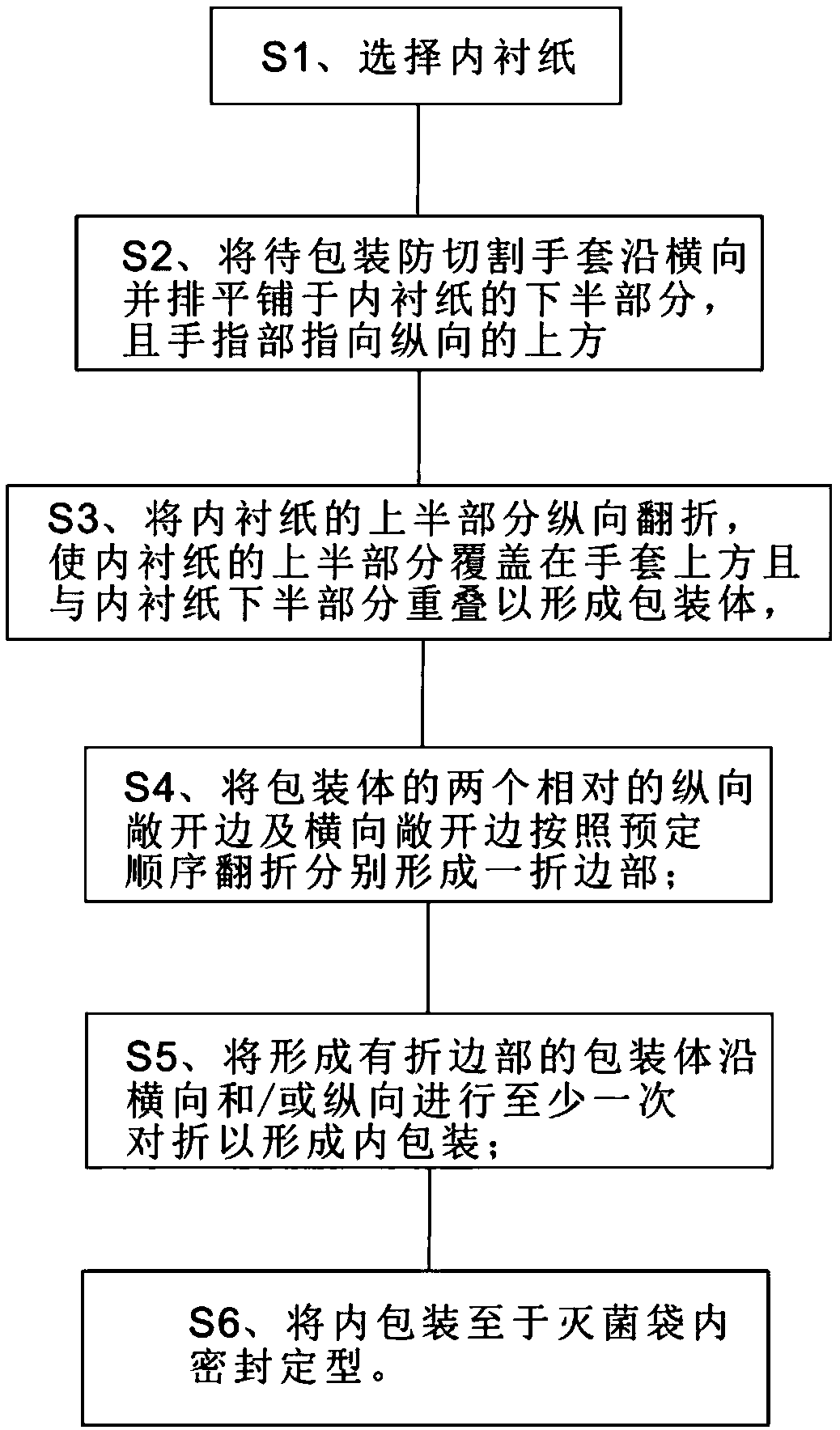

Method used

Image

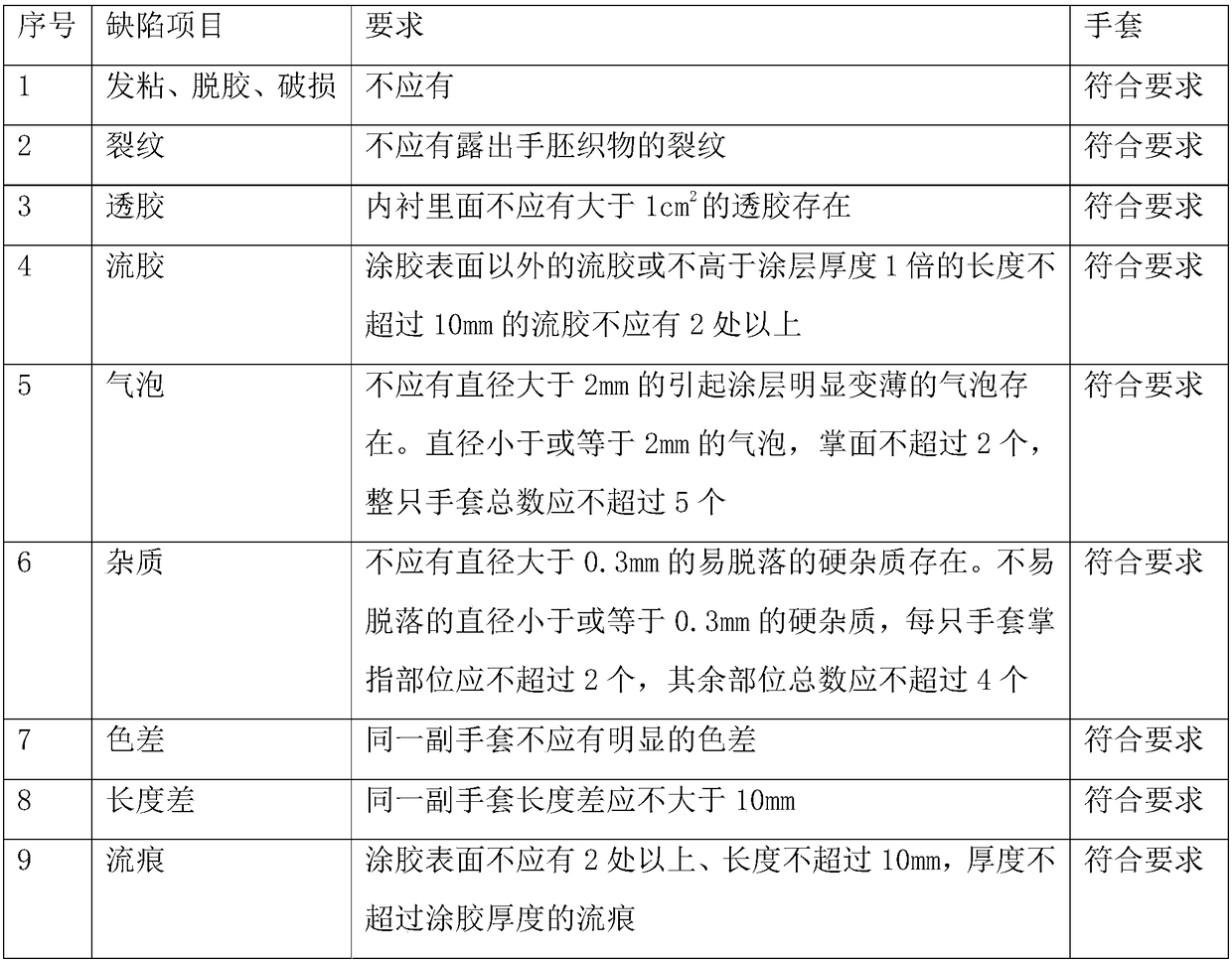

Examples

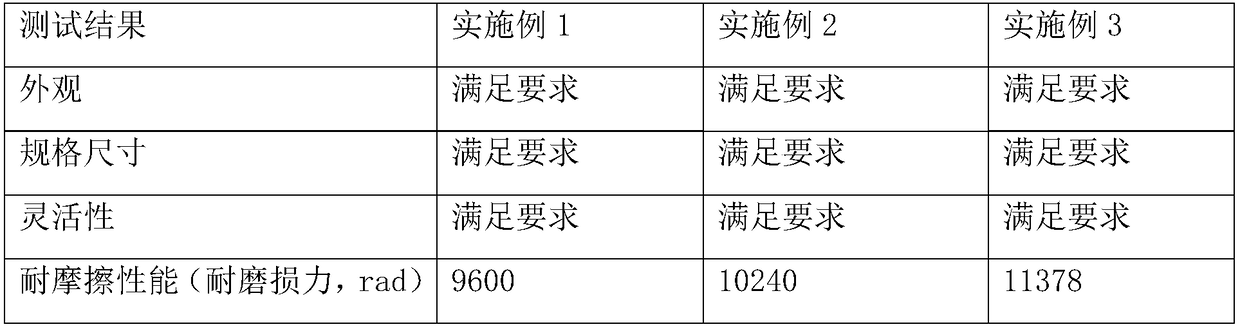

Embodiment 1

[0037] This embodiment discloses a cut-resistant glove, the cut-resistant glove is woven from yarn, the yarn is made of polyethylene / aramid fiber, and the polyethylene / aramid staple fiber blended yarn is single strand. Gloves woven from the above-mentioned yarns have excellent anti-cut performance, which far exceeds national standards and EU standards, and the anti-cut performance will not fail or deteriorate due to washing, and has excellent anti-static and thermal protection properties. It has the advantages of lightness, softness, flexibility, good air permeability, health and environmental protection, good wear resistance and long service life.

[0038] The polyethylene / aramid staple fiber blended yarn is woven into a 10-needle glove core by an automatic glove knitting machine, and the outside of the glove core is also impregnated with a polymer coating, and the polymer coating is nitrile latex.

[0039]The cut-resistant glove is composed of a left-handed glove and a righ...

Embodiment 2

[0041] This embodiment discloses a cut-resistant glove, the cut-resistant glove is woven from yarn, the yarn is made of polyethylene / aramid fiber, and the polyethylene / aramid staple fiber blended yarn is Double-strand, the polyethylene / aramid staple fiber blended yarn is woven by an automatic glove knitting machine with an 18-needle terry machine, and the glove core is a seamless glove core. The outside of the glove core is also impregnated with a polymer coating, and the polymer coating is nitrile latex.

[0042] The cut-resistant glove is composed of a left-handed glove and a right-handed glove. Both the left-handed glove and the right-handed glove include fingers, palms, wrists and sleeves, and the fingers, palms, wrists and sleeves are integrated. It has excellent cut resistance performance, which far exceeds the national standard and EU standard, and the cut resistance performance will not be invalidated or deteriorated due to washing.

Embodiment 3

[0044] This embodiment discloses a cut-resistant glove, the cut-resistant glove is woven by yarn, the yarn is polyethylene / aramid fiber / steel wire, and the yarn is woven into a glove core by an automatic glove knitting machine, The outside of the glove core is also impregnated with a polymer coating, and the polymer coating is polyurethane. The anti-cut gloves of the present invention, the yarn is mixed yarn, anti-stab, anti-tear, wear-resistant, good flame-retardant effect, no combustion-supporting, anti-static, excellent thermal protection performance, light and handy to wear, soft, flexible, and breathable Good, healthy and environmentally friendly, good wear resistance and long service life, etc., suitable for fire protection, electrician, mechanical maintenance and repair, cycling, freight, construction, outdoor, etc.

[0045] The glove core is woven by an automatic glove knitting machine with an 18-needle terry machine, and the glove core is a seamless glove core. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com