Aramid 1414 fiber/spandex coated wire and multifunctional protective socks using same

A technology of spandex covering and spandex yarn, applied in textile and papermaking, weft knitting, yarn and other directions, can solve the problem of limited use range, anti-cutting, flame retardant, wear resistance, health care, wearing comfort and other poor performance, socks products Low added value and other issues, to achieve good anti-cut, comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

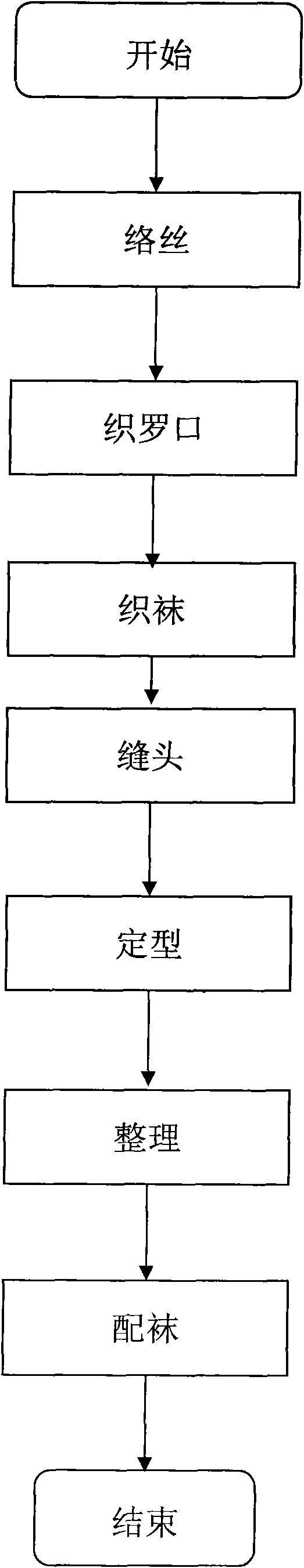

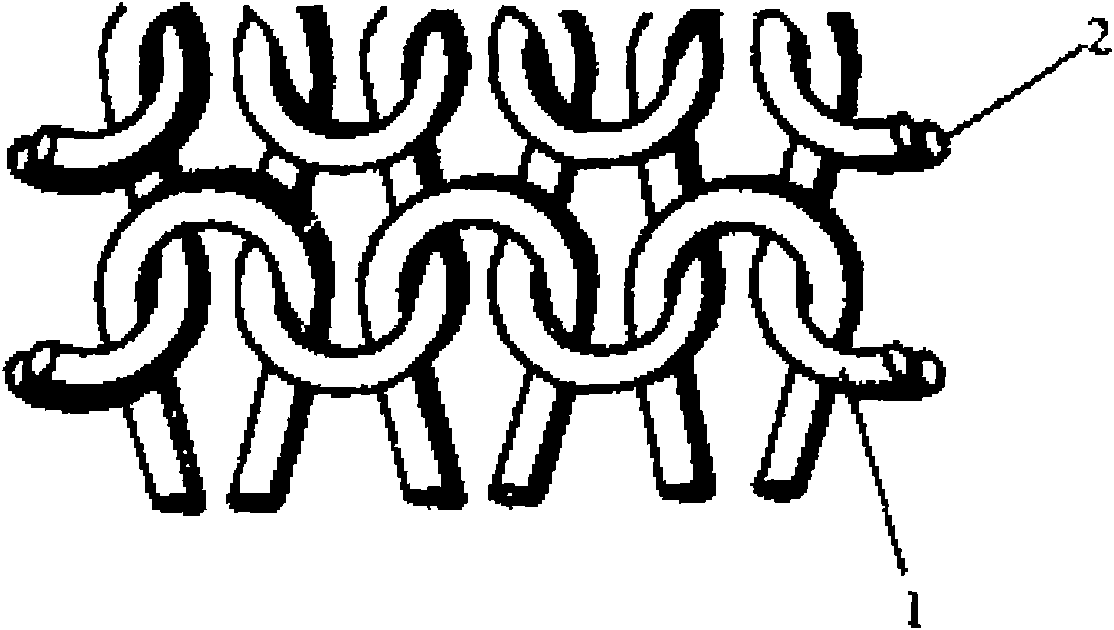

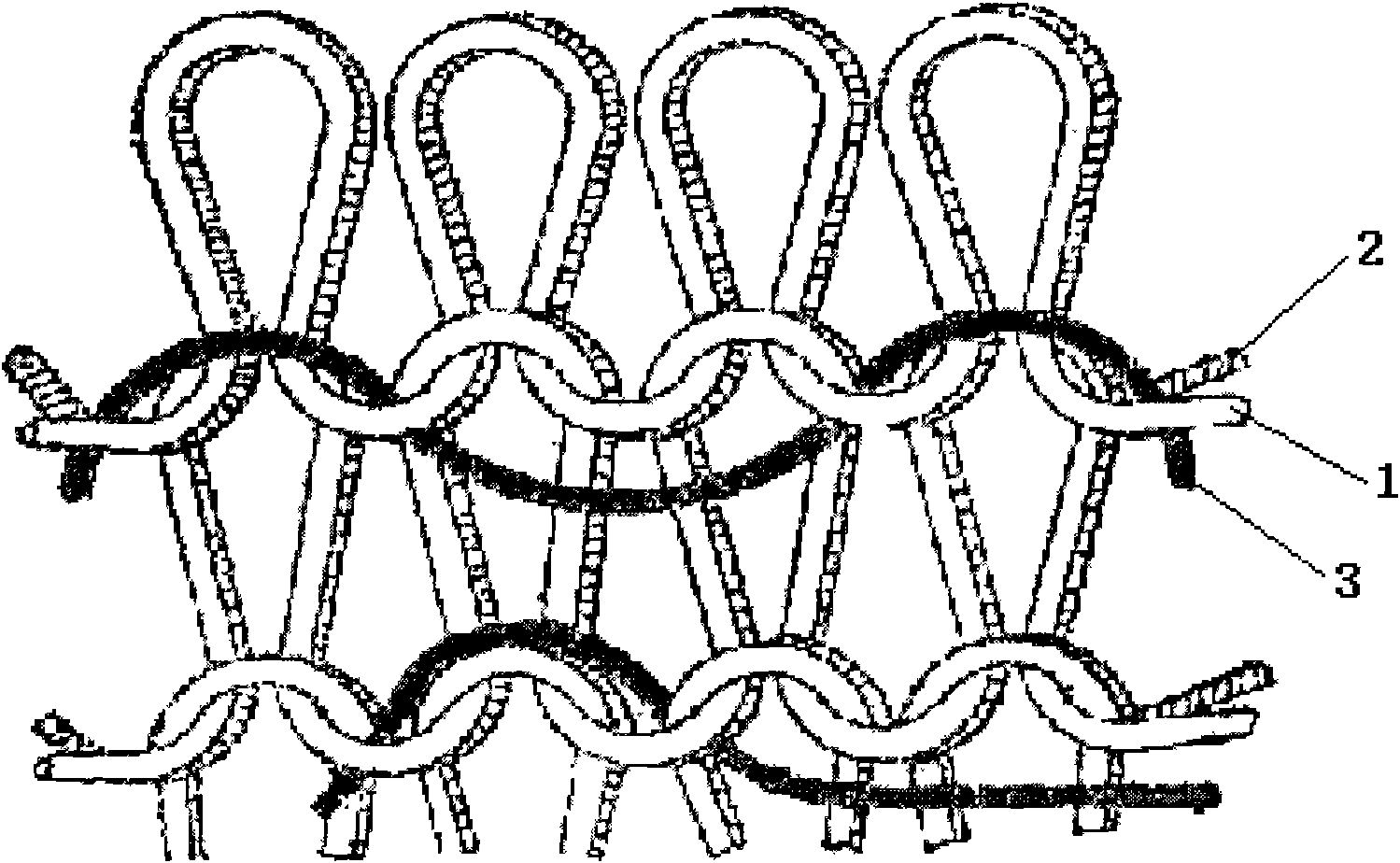

[0015] refer to figure 1 , the processing technology of multi-functional protective socks, which in turn includes the steps of winding, weaving cuffs, weaving socks, sewing head, shaping, finishing, and matching socks. The above-mentioned steps are basically the conventional steps of hosiery knitting, and will not be described in detail. The main feature is that the winding thread includes covering thread 1, yarn 2, and elastic thread 3. Covering thread 1 is a covering thread with spandex thread as the core thread and aramid 1414 fiber as the outer thread. Yarn 2 is combed cotton yarn or aramid 1313 / flame retardant viscose blended yarn. The fineness of spandex yarn is 70D, the fineness of aramid 1414 fiber is 200D, the fineness of the combed cotton yarn is 21S, the fineness of aramid 1313 / flame-retardant viscose blended yarn is 32S, and the elastic silk 3 Use 100# elastic wire. Such as figure 2 As shown, when weaving hosiery, the sock is woven by covering yarn 1 and yarn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com