Protective glove with enhanced exterior sections

a glove and enhanced technology, applied in the field of protective gloves with enhanced exterior sections, can solve the problems of time-consuming and separate inverting operation, and achieve the effect of enhancing cut resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

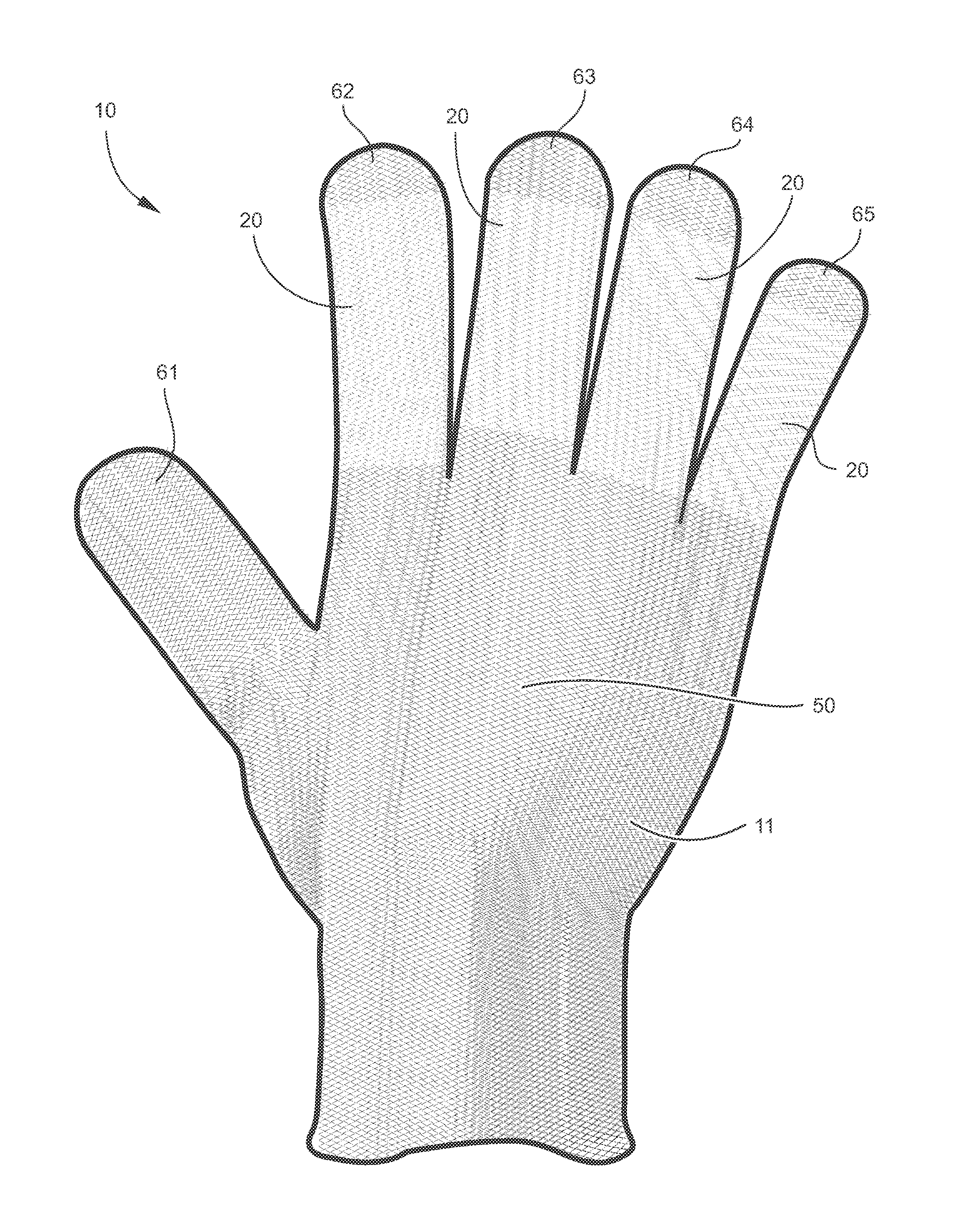

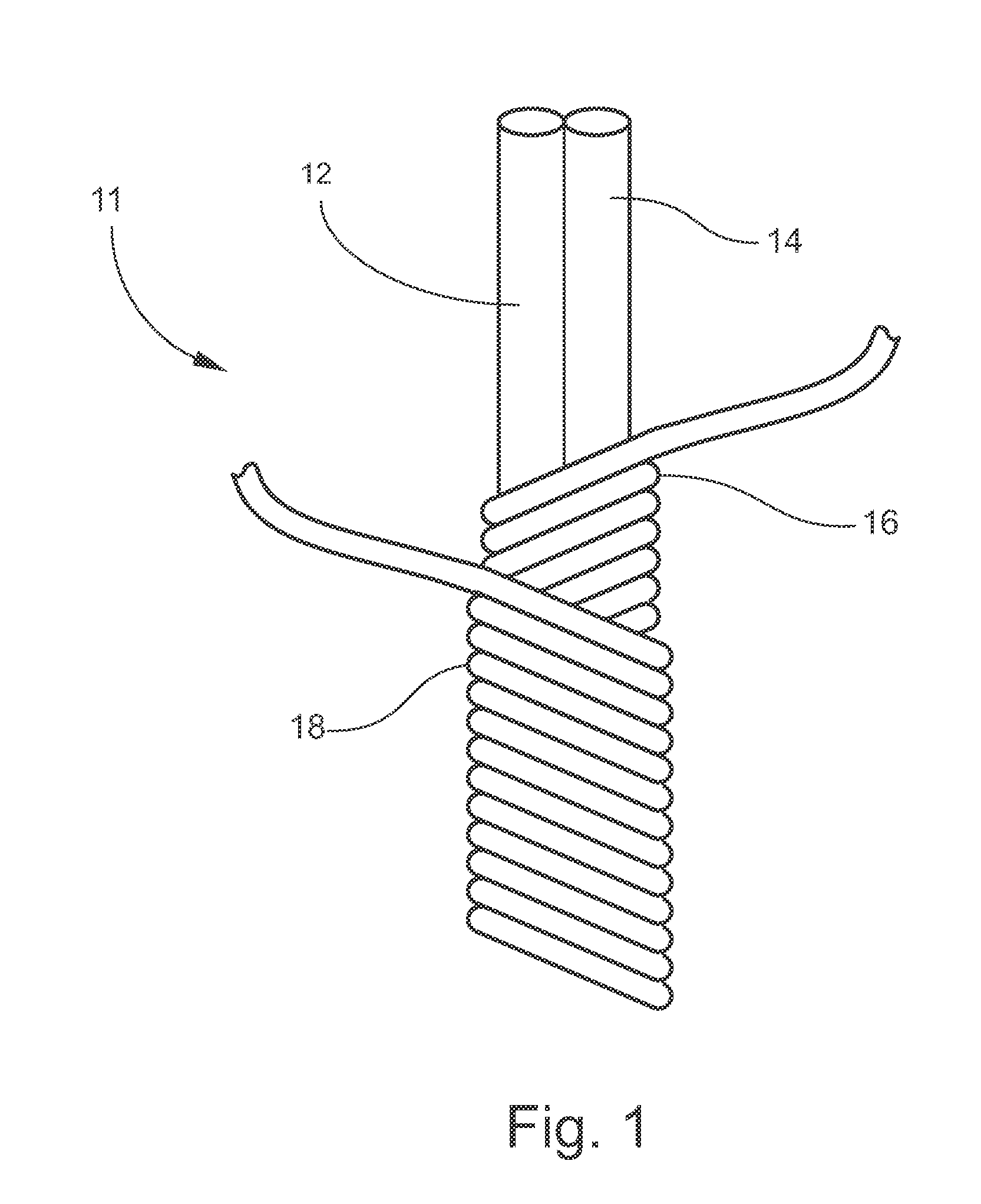

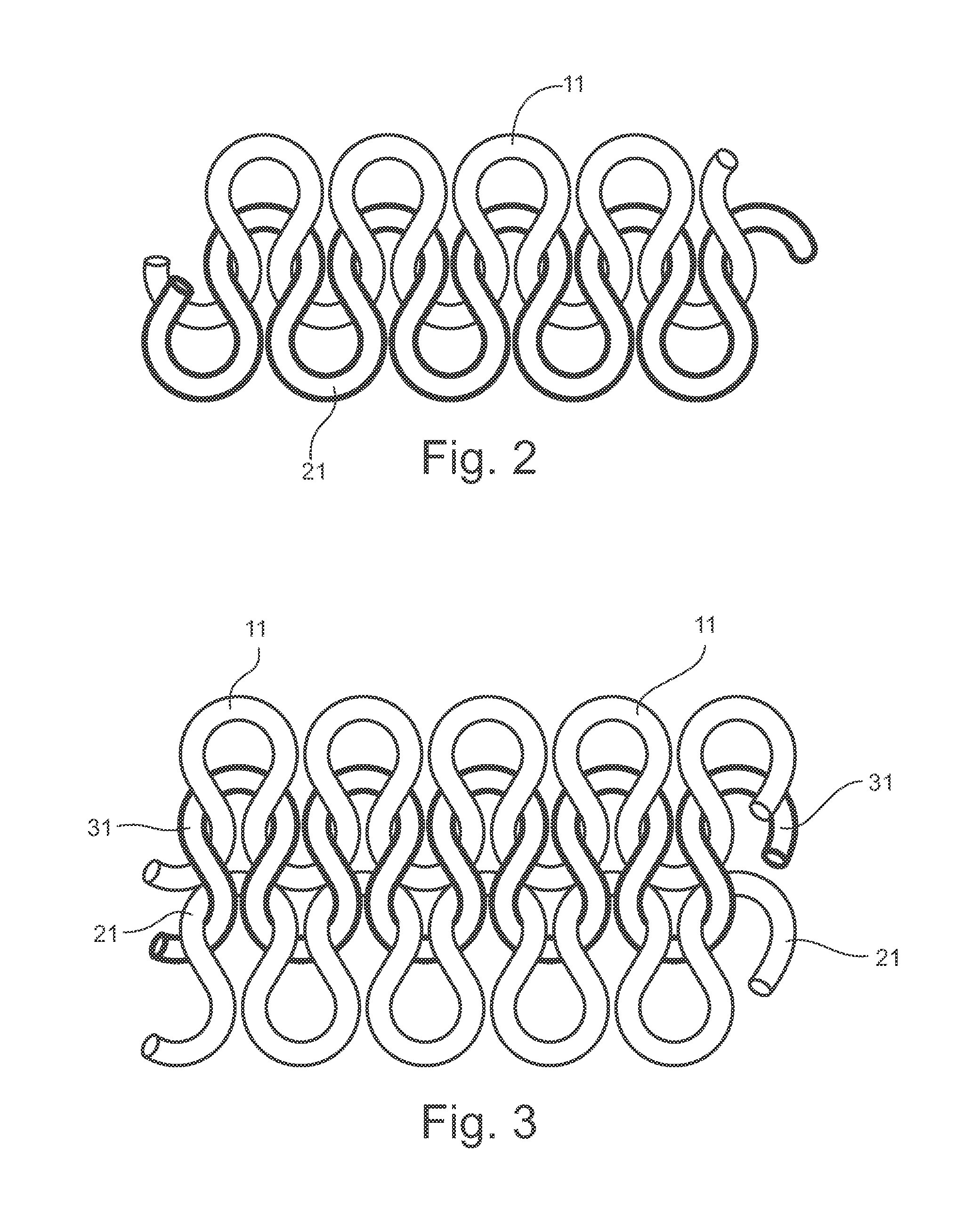

[0049]A protective glove according to a preferred embodiment of the invention is illustrated in FIGS. 1-6, and shown generally at reference numeral 10. The glove 10 is comprised of an inner primary yarn 11, and a plaiting yarn 21 having cut resistance properties plaited to the primary yarn 11. The inner primary yarn 11 can be comprised of a first core strand 12 of 450 (one hundred denier) fiberglass and a second core strand 14 comprised of four hundred denier ultra-high molecular weight polyethylene (UHMWPE), a first covering strand 16 of one-hundred fifty denier textured polyester wrapped around the core stands 12, 14, and a second covering strand 18 of one-hundred fifty denier textured polyester wrapped over the first cover strand 16, as shown in FIG. 1. As shown in FIG. 1, the first cover strand 16 is wrapped in an S orientation, while the second cover strand 18 is wrapped in a Z orientation. Alternatively, the first cover strand 16 can be wrapped in a Z orientation, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com