Nutrition stewing sauce and preparation method thereof

A technology of stew sauce and nutrition, which is applied in the field of nutrition stew sauce and its preparation, can solve the problems of poor shape preservation effect, few types of nutrients, and single taste, so as to improve freeze-thaw stability, overcome low nutrition, Delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

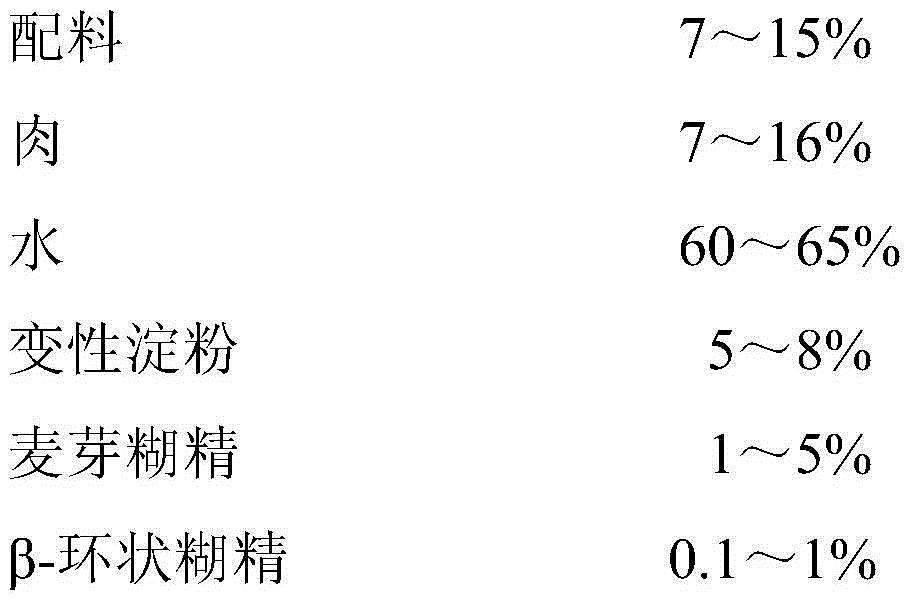

[0040] (1) Select 500g of corn, 470g of carrot, 70g of shiitake mushroom and 30g of ginseng as ingredients to slice and dice, then clean and set aside;

[0041] (2) Take 1.5kg of pork for cleaning, cut it into small pieces of 1.5cm×1.5cm×1.5cm and put it into the reaction kettle together with the ingredients, add 6.2kg of water into the reaction kettle and stir evenly, heat it to boiling and then control the firepower, Keep boiling for 3.5 hours;

[0042] (3) Leak out the soup dregs, remove the bones and corncobs to obtain the dregs;

[0043] (4) Add 530g of modified starch to the soup after draining out the soup dregs, boil until boiling, keep for 20 minutes, then add 200g of maltodextrin, 20g of β-cyclodextrin, 10g of guar gum, and 300g of xanthan gum , L-ascorbyl palmitate 2g, phospholipid 40g, salt 48g, β-carotene 28g, nucleotide disodium 1g, monosodium glutamate 50g and sodium dehydroacetate 1g, stirred at 40°C for 30 minutes, and the stirring speed was controlled at 10...

Embodiment 2

[0046] (1) Select 500g of shelled chestnuts, 325g of peanuts, 200g of shiitake mushrooms, 100g of red dates, 100g of wolfberry and 100g of sliced Gastrodia elata as ingredients, clean and reserve;

[0047] (2) Take 1.2kg of chicken for cleaning, cut it into small pieces of about 1.5cm×1.0cm×1.5cm and add it to the reaction kettle together with the ingredients, add 6.1kg of water into the reaction kettle and stir evenly, heat it until it boils and then control the firepower , keep boiling and simmer for 4 hours;

[0048] (3) Drain the soup dregs, remove the bones and jujube pits to obtain the dregs;

[0049] (4) Add 800g of modified starch to the soup after draining the soup dregs, boil until boiling, keep for 20 minutes, then add 100g of maltodextrin, 10g of β-cyclodextrin, 200g of guar gum, and 100g of xanthan gum , L-ascorbyl palmitate 1g, phospholipid 50g, salt 50g, β-carotene 30g, nucleotide disodium 3g, monosodium glutamate 30g and sodium dehydroacetate 1g, stirred at ...

Embodiment 3

[0052] (1) Select 400g of diced Chinese yam, 100g of barley and 200g of peanut as ingredients, wash and set aside;

[0053] (2) Take 1.6kg of pork for cleaning, cut into small pieces of about 1.0cm×1.5cm×1.0cm, put them into the reaction kettle together with the ingredients, add 6.0kg of water into the reaction kettle and stir evenly, heat it until it boils and then control the firepower , keep boiling and simmer for 4 hours;

[0054] (3) Leak out the soup dregs, remove the bones, and obtain the dregs;

[0055] (4) Add 600g of modified starch to the soup after draining out the soup dregs, boil until boiling, keep for 20 minutes, then add 460g of maltodextrin, 60g of β-cyclodextrin, 100g of guar gum, and 268g of xanthan gum , L-ascorbyl palmitate 2g, phospholipid 80g, salt 40g, β-carotene 20g, nucleotide disodium 5g, monosodium glutamate 60g and sodium dehydroacetate 5g, stirred at 50°C for 20 minutes, and the stirring speed was controlled at 100 rpm, control the solid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com