Patents

Literature

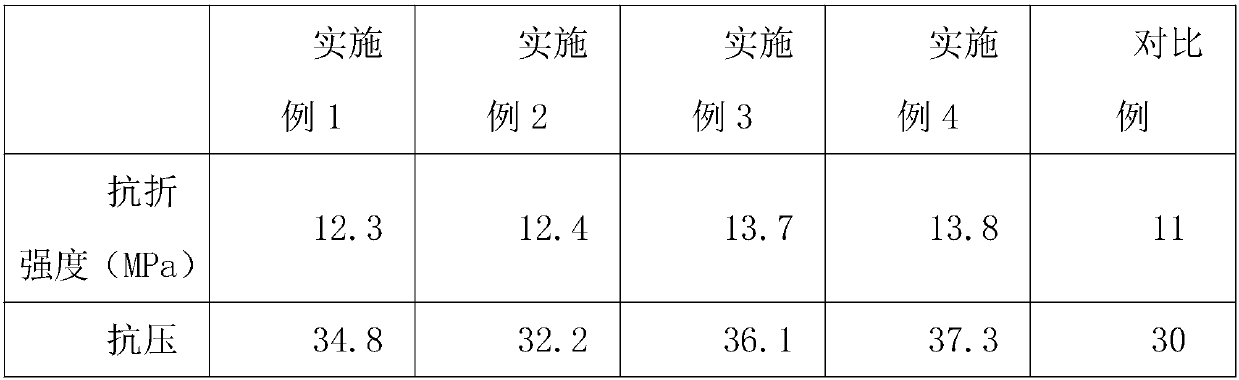

42results about How to "Solve easy collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of super-hydrophobic polytetrafluoroethylene membrane

ActiveCN104998557AUnique structureSolve easy collapseMembranesSemi-permeable membranesSolventEmulsion

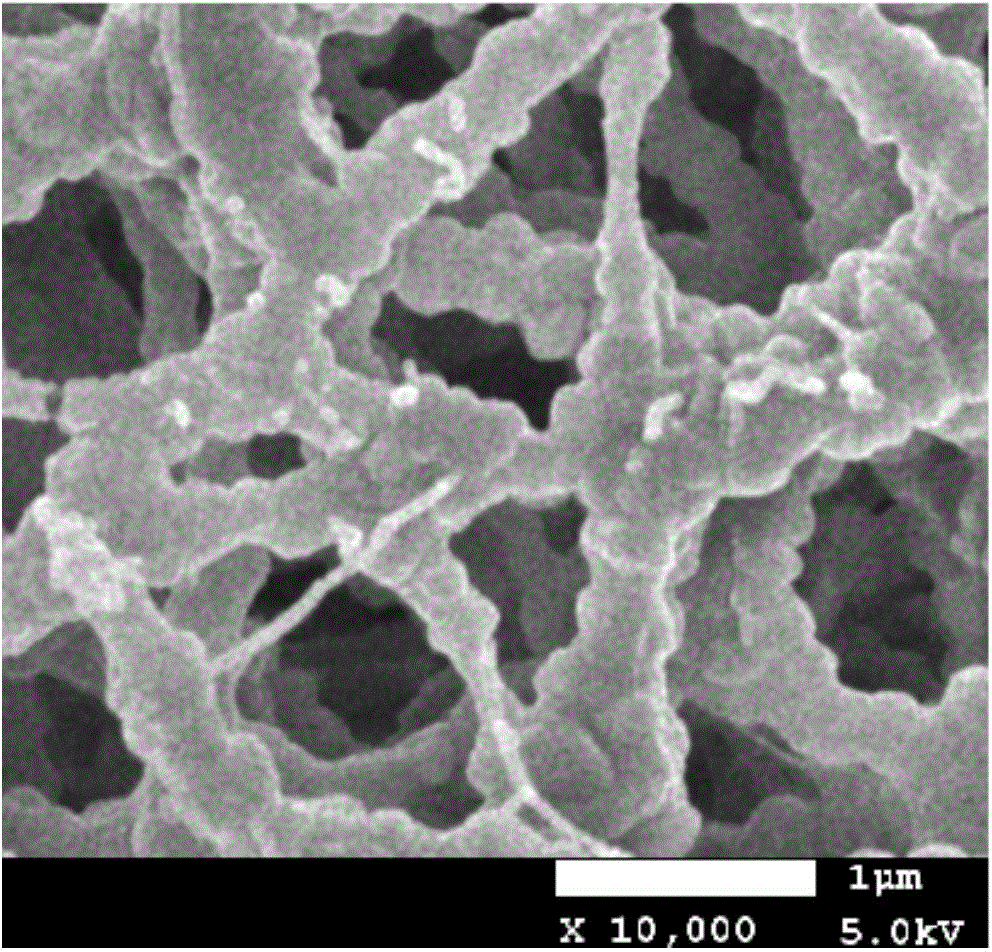

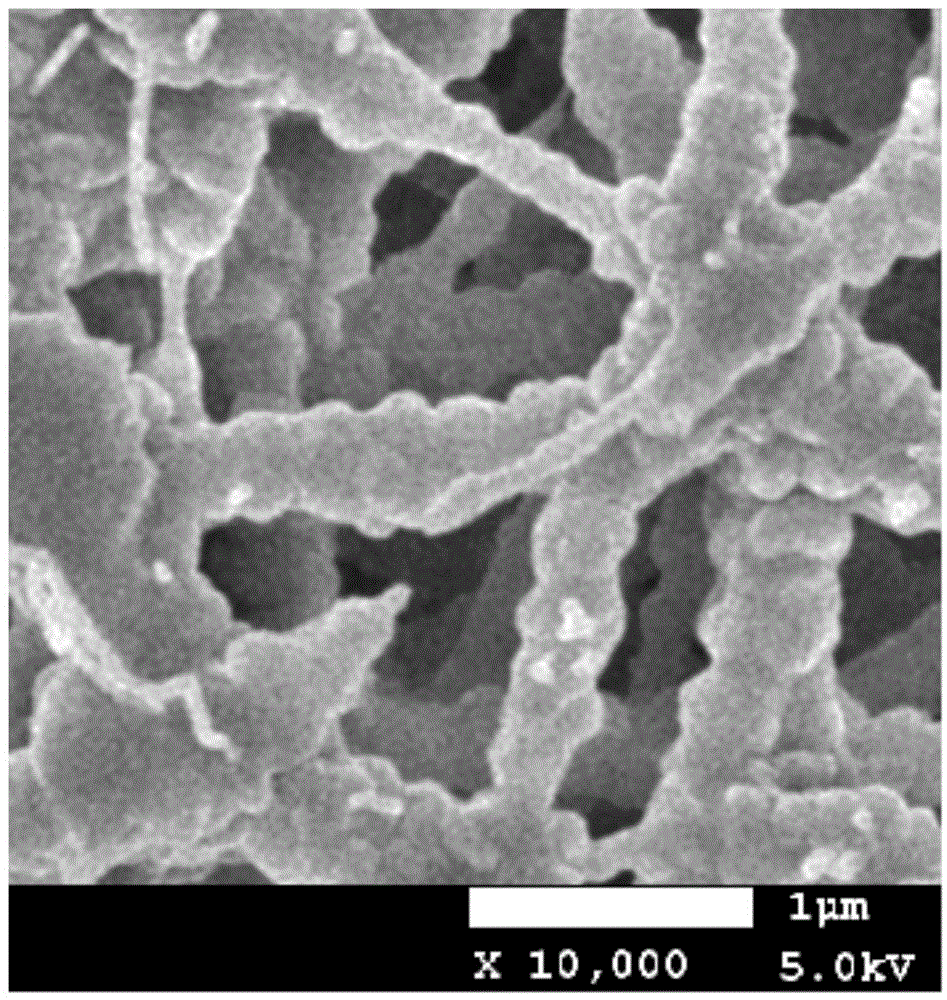

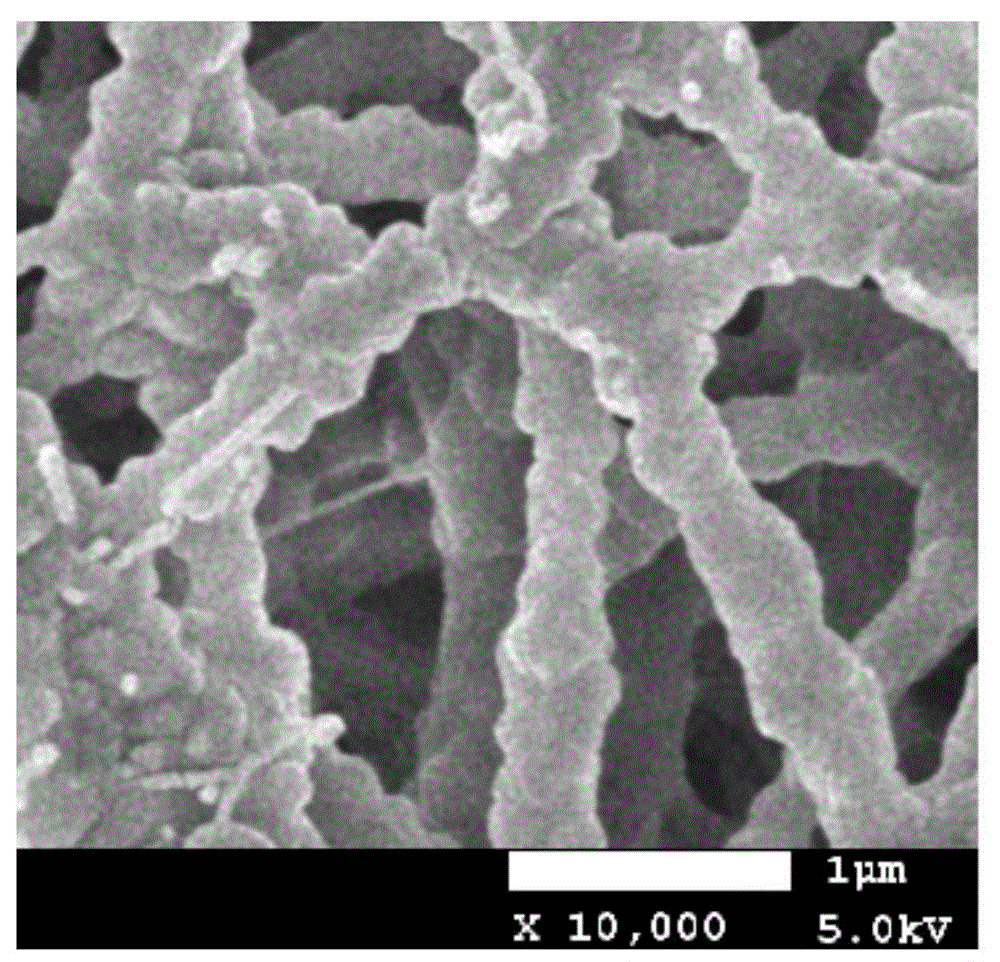

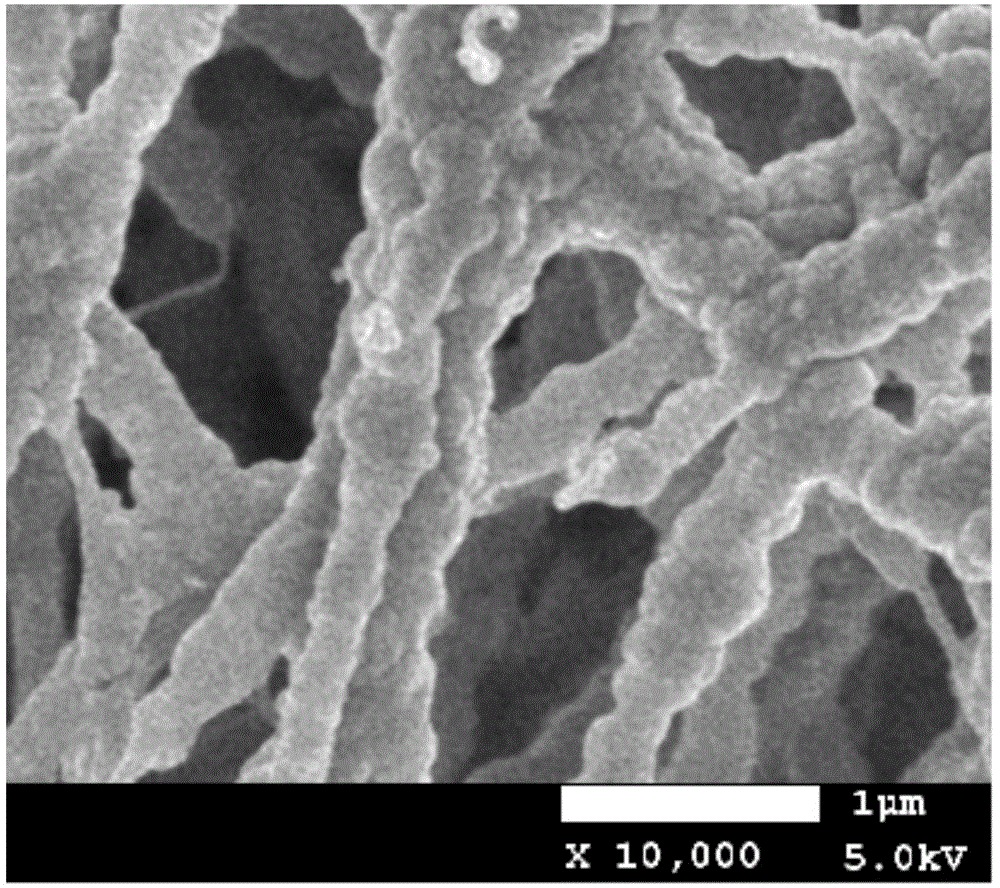

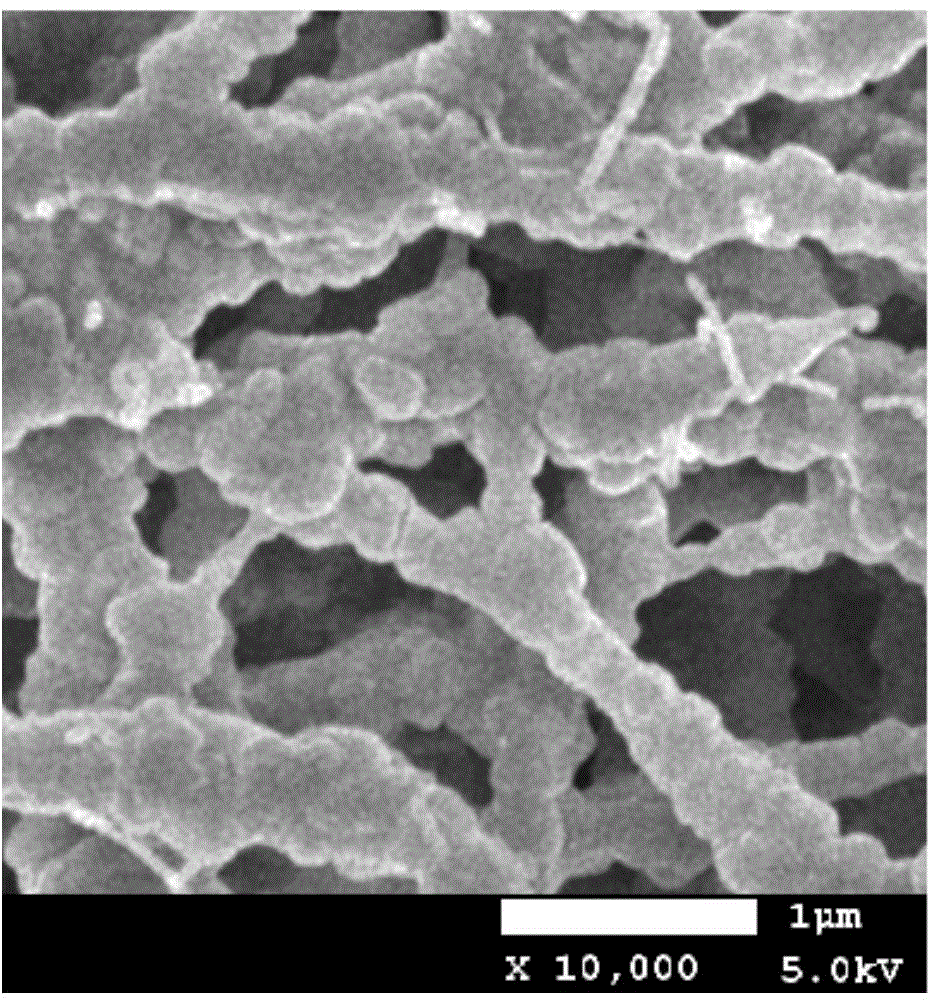

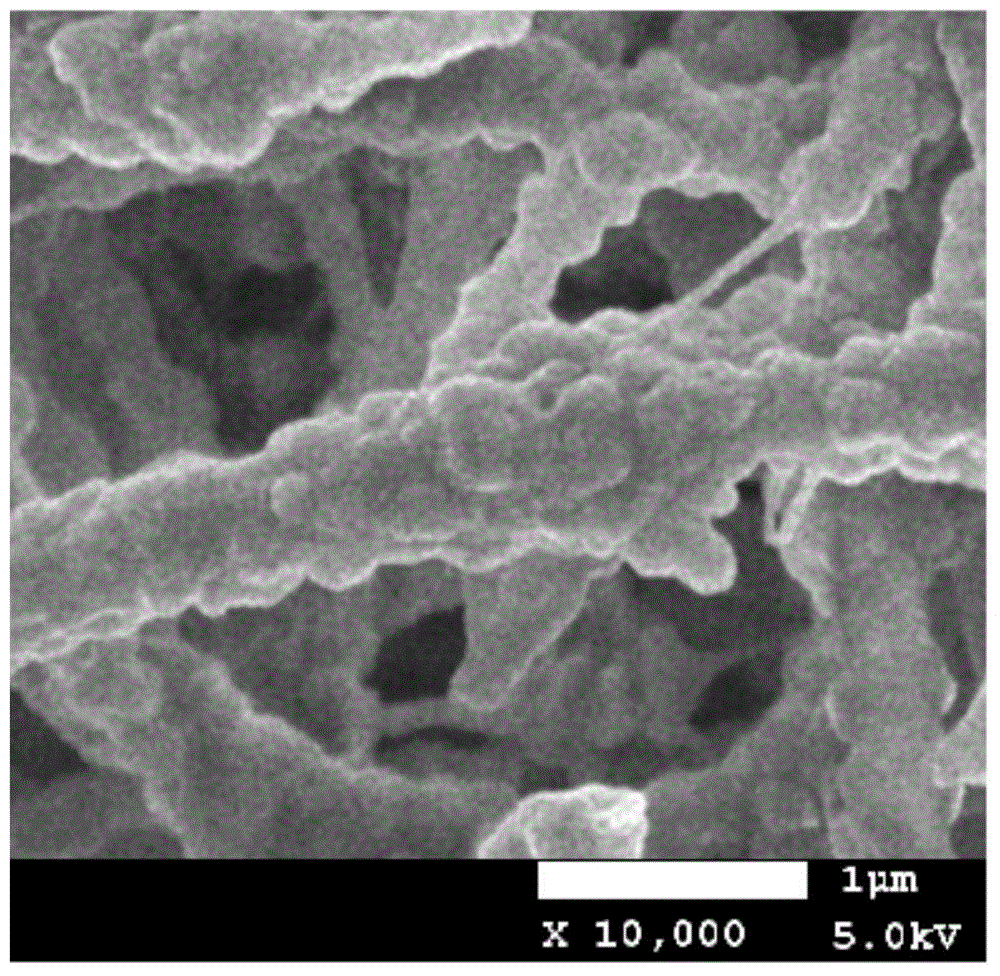

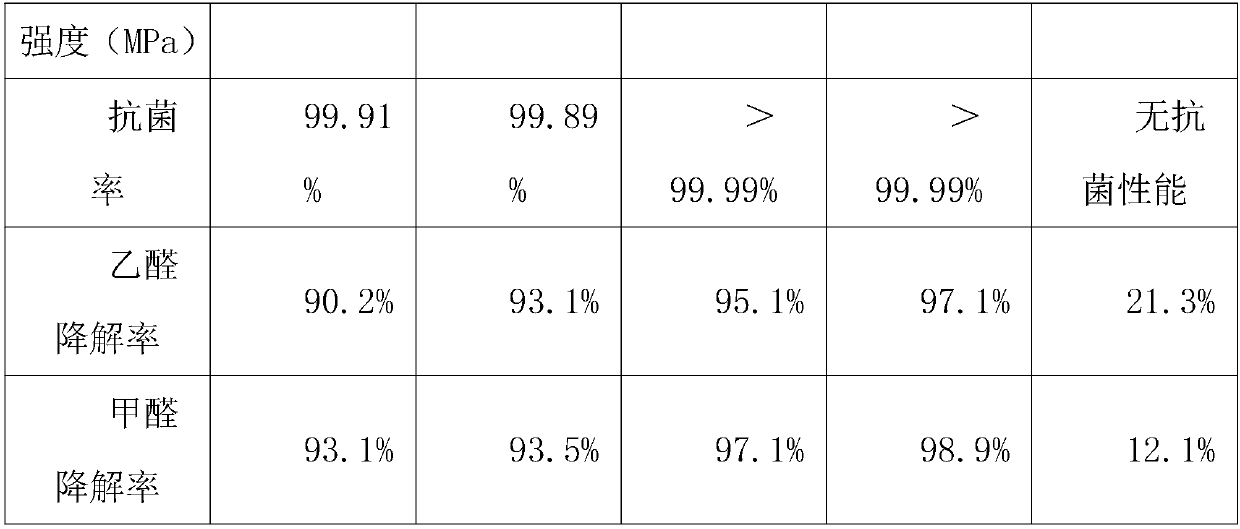

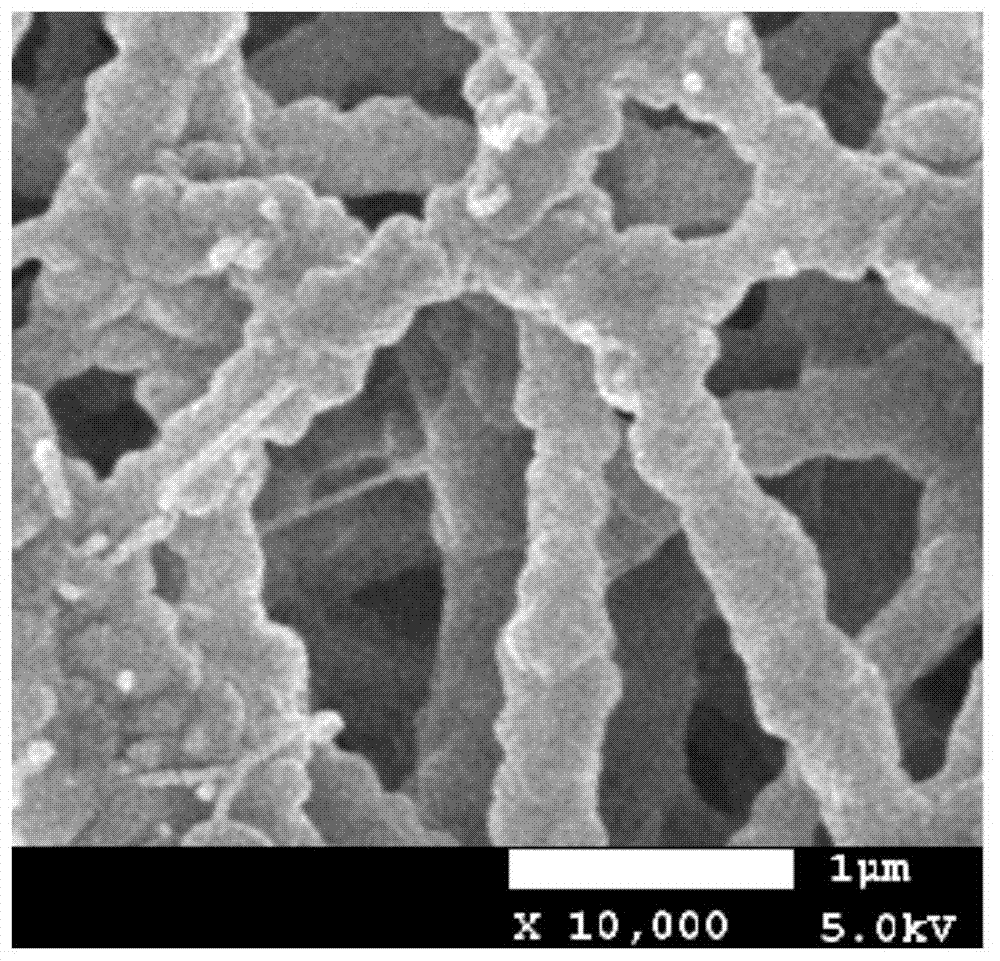

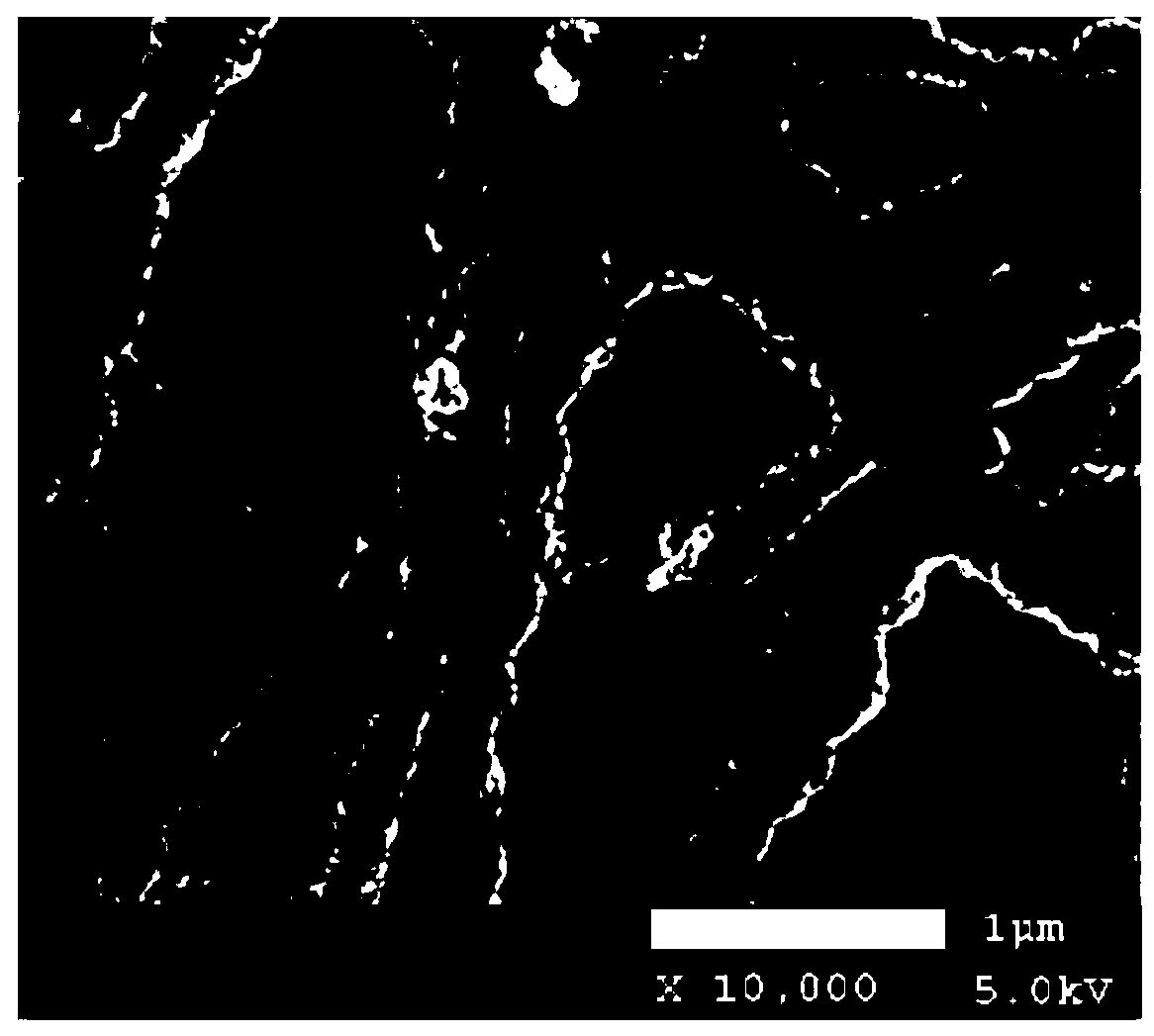

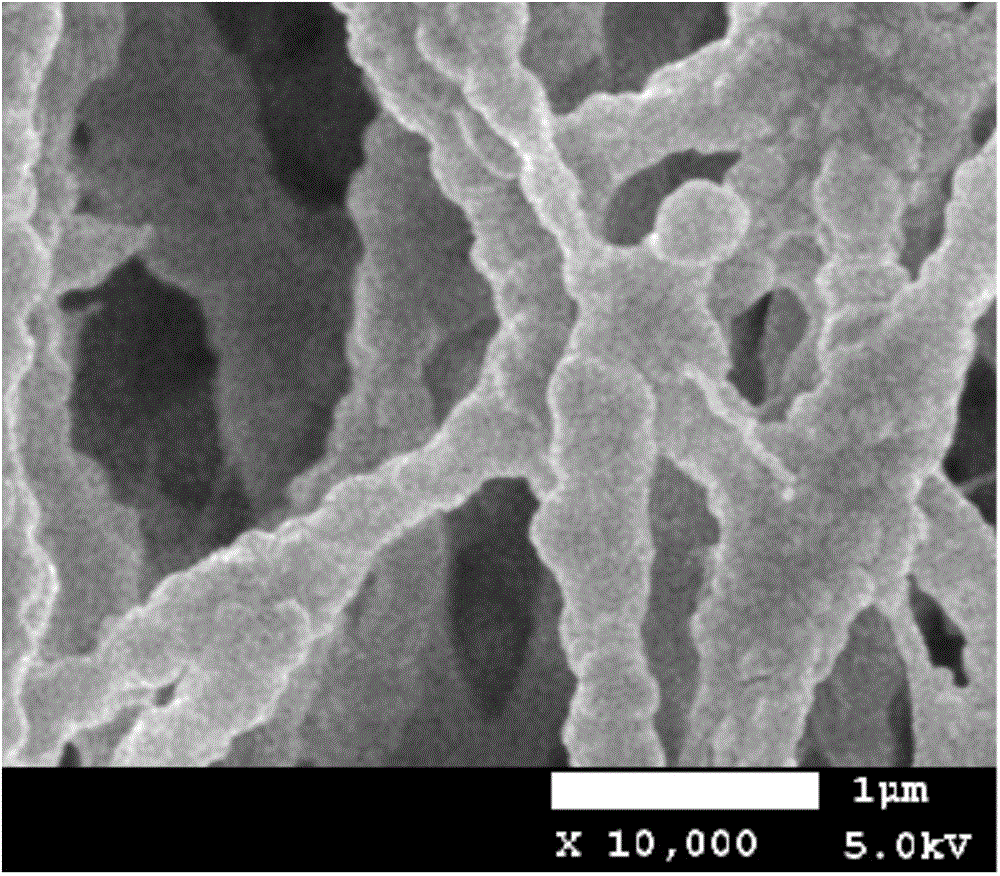

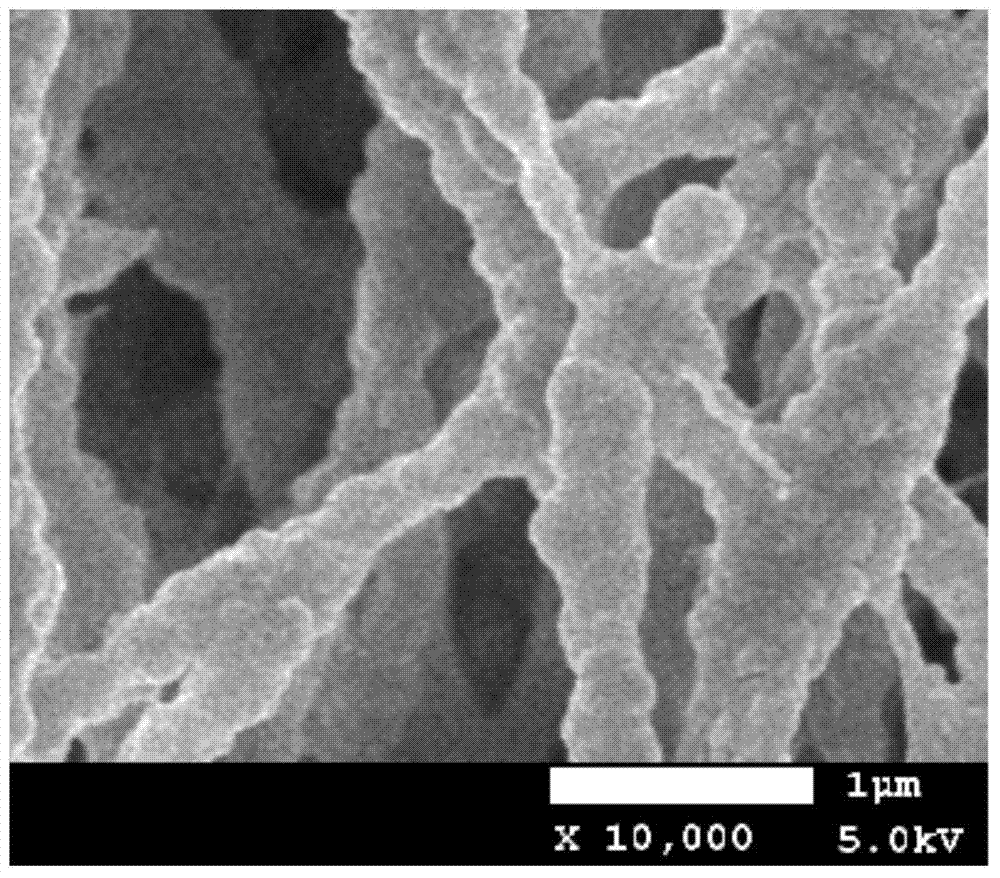

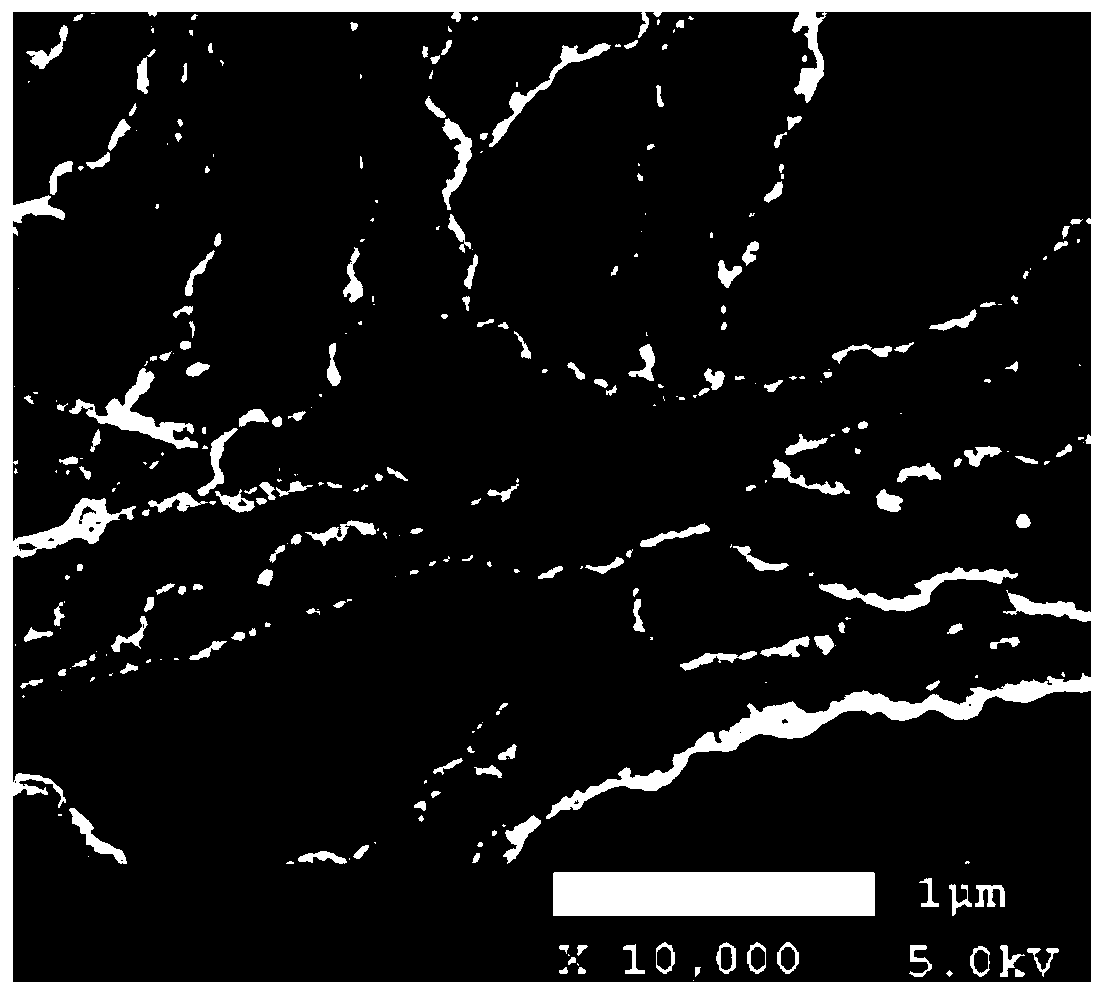

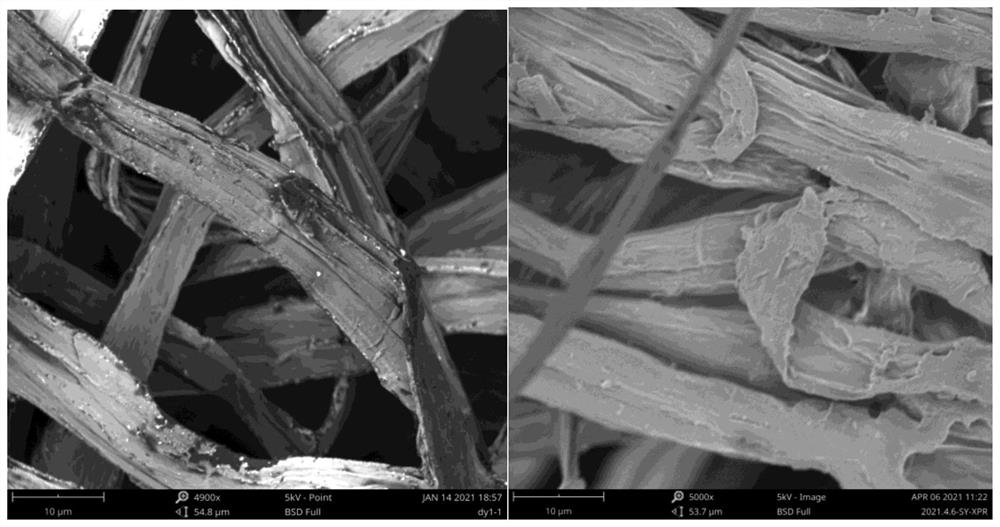

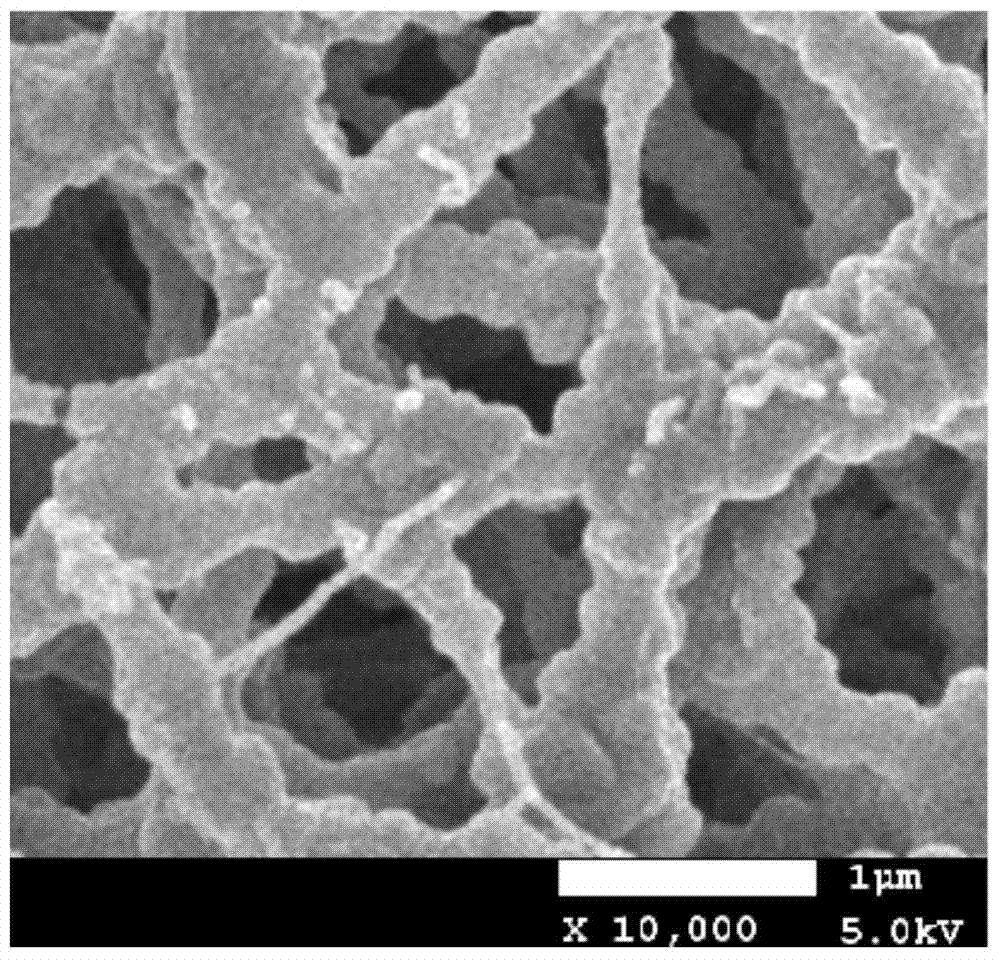

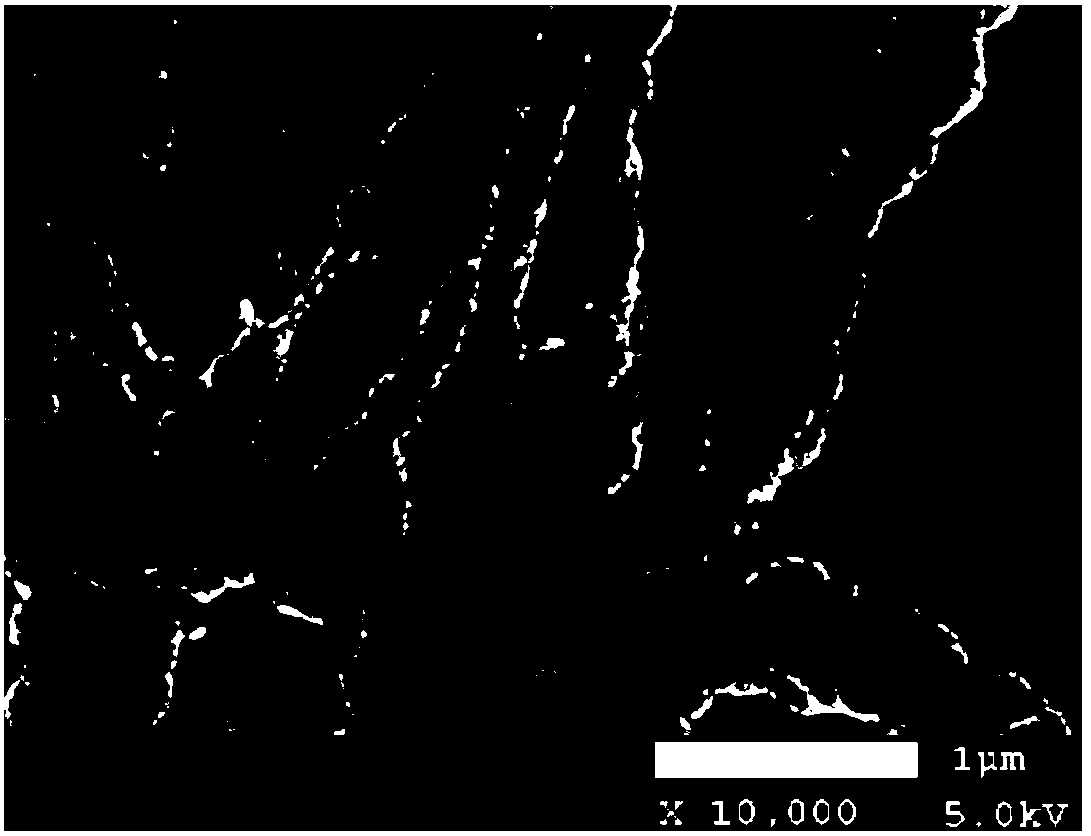

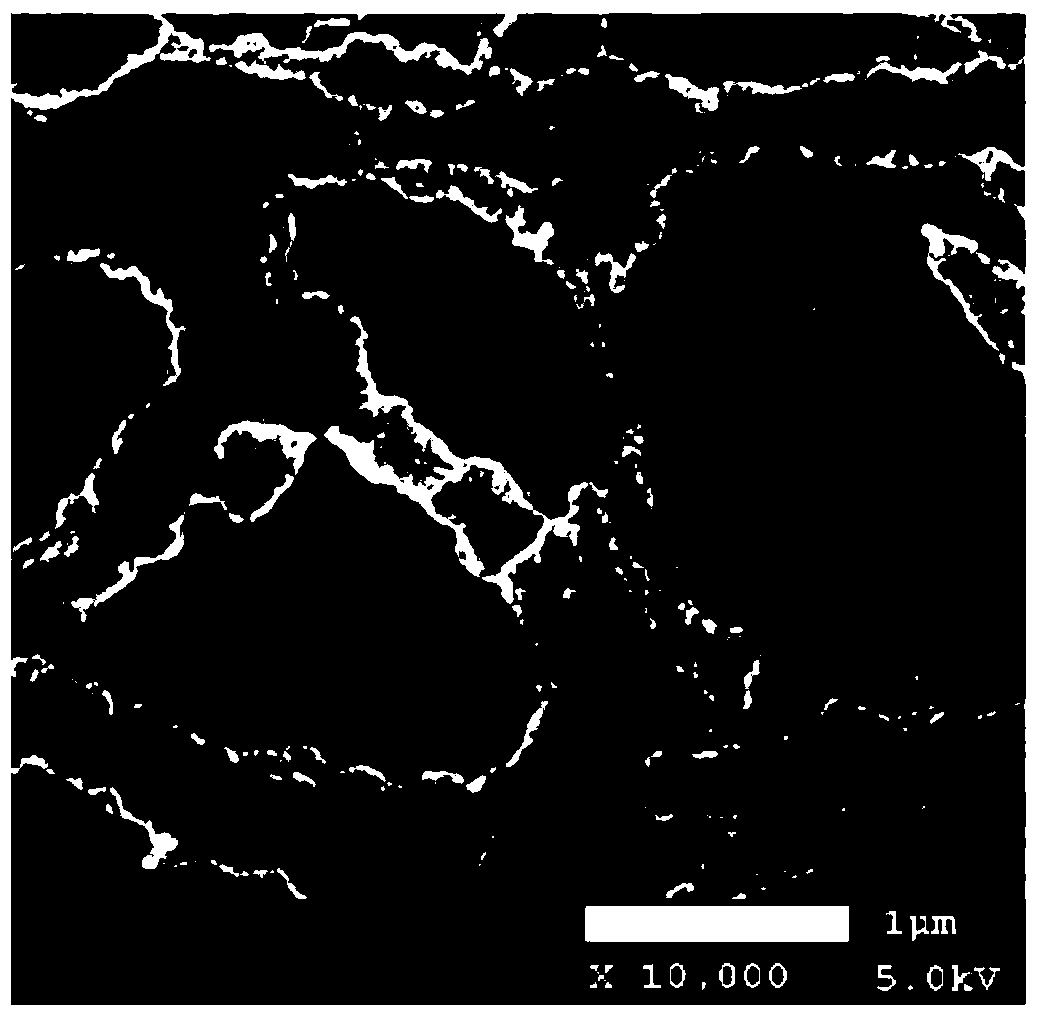

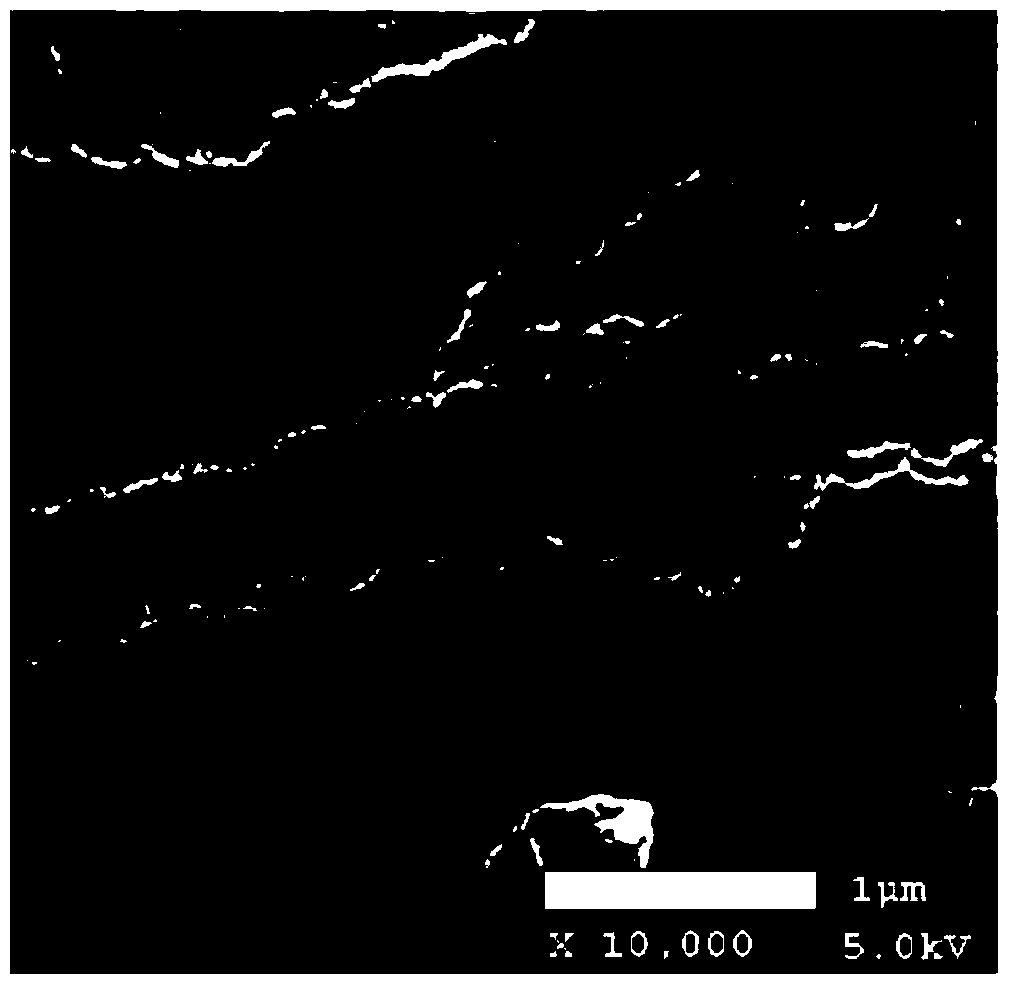

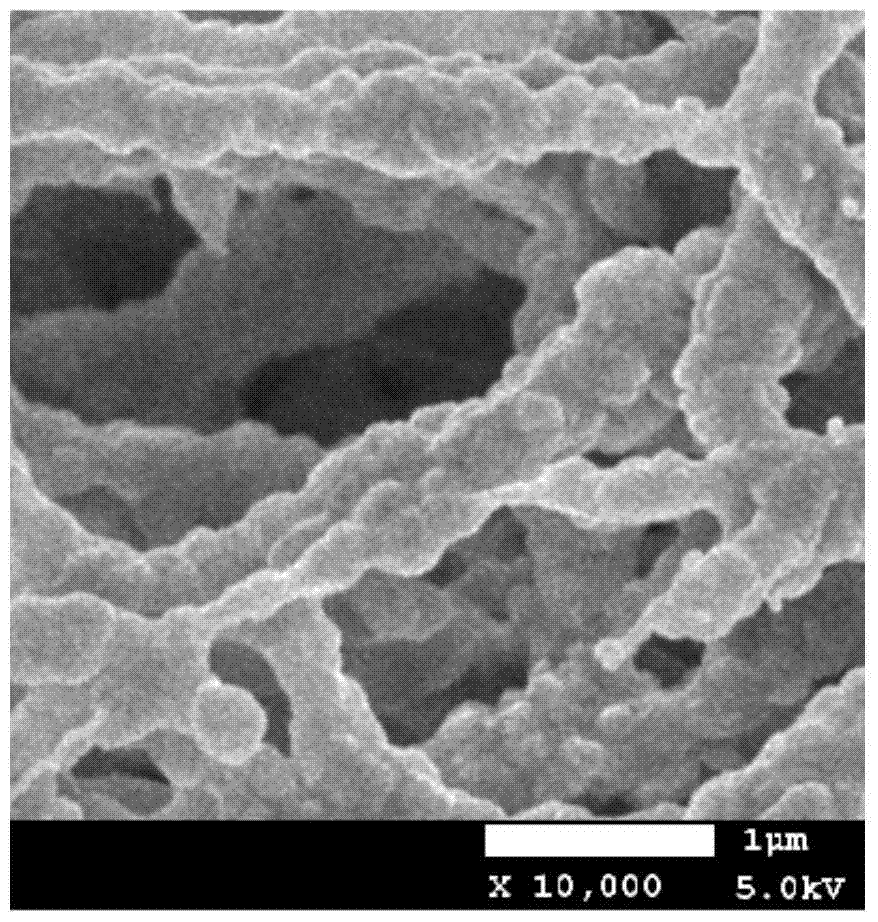

The invention provides a production method of a super-hydrophobic polytetrafluoroethylene membrane. The method comprises the steps of preparing a spinning solution, producing fibers, and sintering, wherein a fiber forming carrier and a solvent are adopted to prepare a solution, a polytetrafluoroethylene emulsion is added, the fiber forming carrier is polyacrylic acid, and the solvent is water; and the sintering step adopts temperature programmed control sectional continuous sintering, and is characterized by carrying out heat insulation in flowing atmosphere at 90-120DEG C for 30-120min, heating to 260-300DEG C from 90-120DEG C at a rate of 3-10DEG C / min, carrying out heat insulation at 260-300DEG C for 30-120min, heating to 370-390DEG C from 260-300DEG C at a rate of 2-8DEG C / min, and carrying out heat insulation at 370-390DEG C for 5-120min. The method well solves the problem of easy collapsing of fibers in the sintering process of a polytetrafluoroethylene precursor membrane, and allows the beaded ultrafine fiber netted membrane, disordered stacking between fibers becomes mutual adhesion, and the fibers have the characteristics of uniform form, complete surface, and greatly improved strength and toughness, and can bear a certain vacuum pressure.

Owner:成都百途医药科技有限公司

Nutrition stewing sauce and preparation method thereof

InactiveCN104012942ASolve easy collapseAddresses technical deficiencies of variantsFood ingredientsFood preparationBeta-CaroteneAdditive ingredient

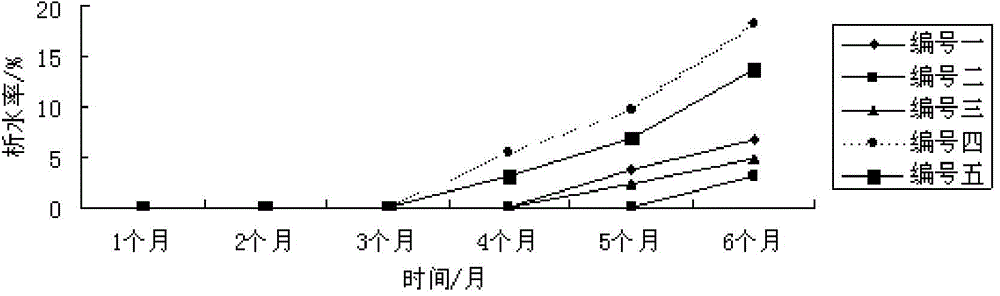

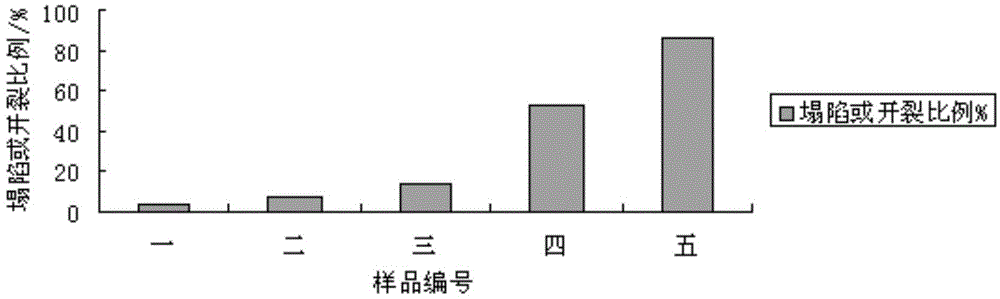

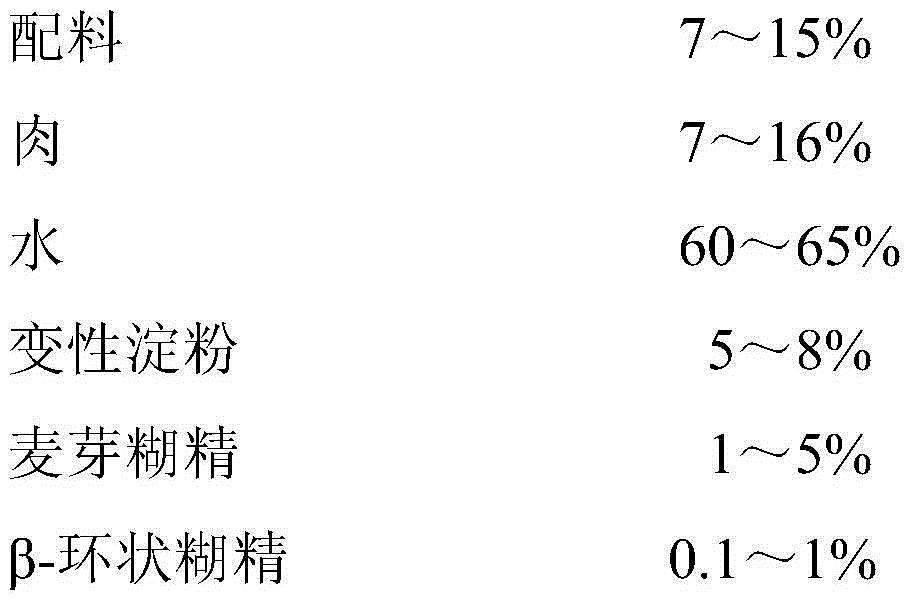

The invention belongs to the technical field of food processing, and discloses a nutrition stewing sauce and a preparation method thereof. The nutrition stewing sauce is prepared from the following raw materials by weight: 7-15% of ingredients, 7-16% of meat, 60-65% of water, 5-8% of modified starch, 1-5% of maltodextrin, 0.1-1% of beta-cyclodextrine, 0.1-2% of guar gum, 1-3% of xanthan gum, 0.01-0.02% of L-Ascorbyl palmitate, 0.4-1.0% of phospholipid, 0-0.3% of beta-carotene, 0.3-0.5% of salt, 0.01-0.05% of disodium nucleotide, 0.3-1.0% of aginomoto and 0.01-0.05% of sodium dehydroacete. The traditional nutrition stewing technology of slowly stewing by small fire at south of the five ridges is combined with the modern food processing technology to prepare the sauce special for baked food stuffing, and the traditional technology and the modern technology are perfectly combined.

Owner:GUANGZHOU FOOD IND RES INST

Super-hydrophobic polytetrafluoroethylene fiber membrane preparation method

ActiveCN104998556AUnique structureSolve easy collapseSemi-permeable membranesFiberThermal insulation

The present invention provides a polytetrafluoroethylene fiber membrane preparation method, which comprises spinning liquid preparing, fiber preparing and sintering, and is characterized in that a polytetrafluoroethylene emulsion is added after a fiber-forming carrier and a solvent form a solution, wherein the fiber-forming carrier is polyacrylic acid, and the solvent is water; the sintering adopts the programmed temperature control sectional continuous sintering, wherein under a flowing atmosphere, thermal insulation is performed for 30-120 min at a temperature of 90-120 DEG C, heating is performed from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min, thermal insulation is performed for 30-120 min at a temperature of 260-300 DEG C, heating is performed from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min, and thermal insulation is performed for 5-120 min at a temperature of 370-390 DEG C; and the cooling treatment after the sintering comprises that the cooling is performed from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min under a flowing atmosphere, thermal insulation is performed for 30-120 min at a temperature of 150-200 DEG C, and then natural cooling is performed.

Owner:四川百途环保材料科技有限公司 +2

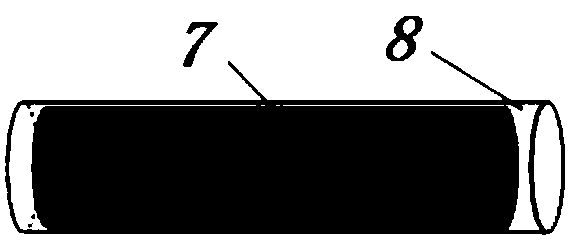

Polypyrrole-coated cattail wool-based ultra-light biomass porous foam as well as preparation method and application thereof

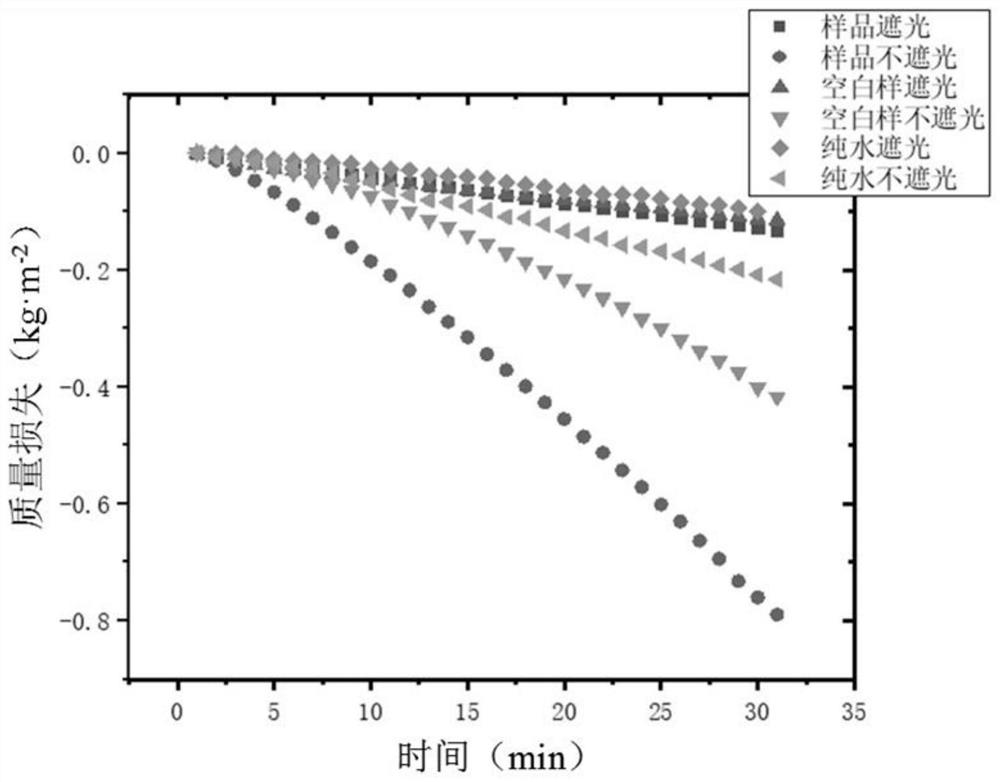

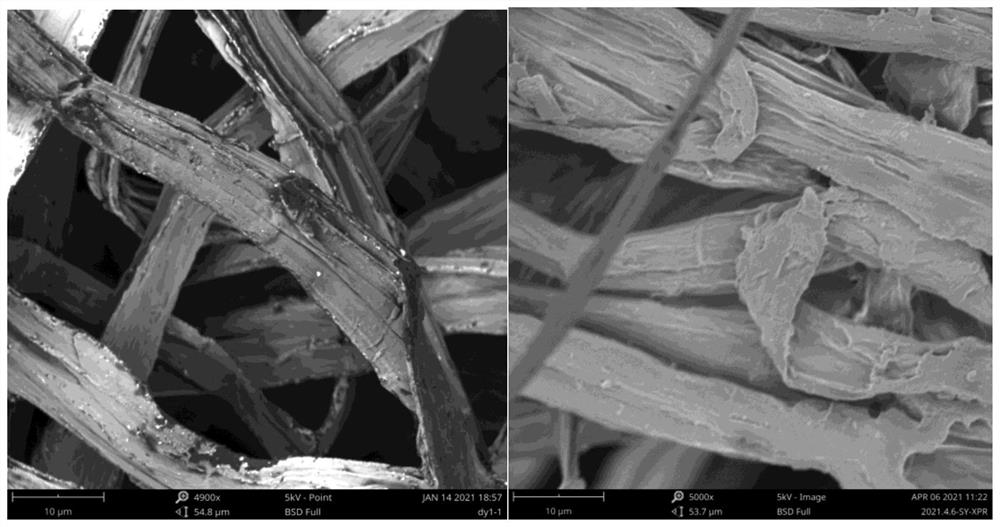

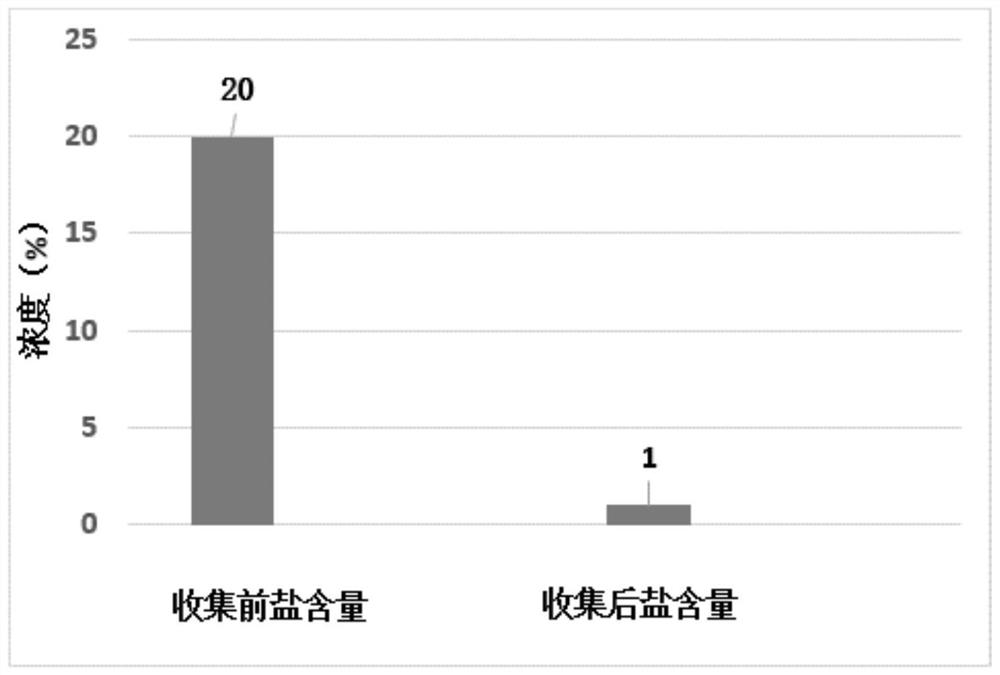

ActiveCN113321939AImprove mechanical propertiesImprove salt toleranceGeneral water supply conservationSeawater treatmentPolymer sciencePolypyrrole

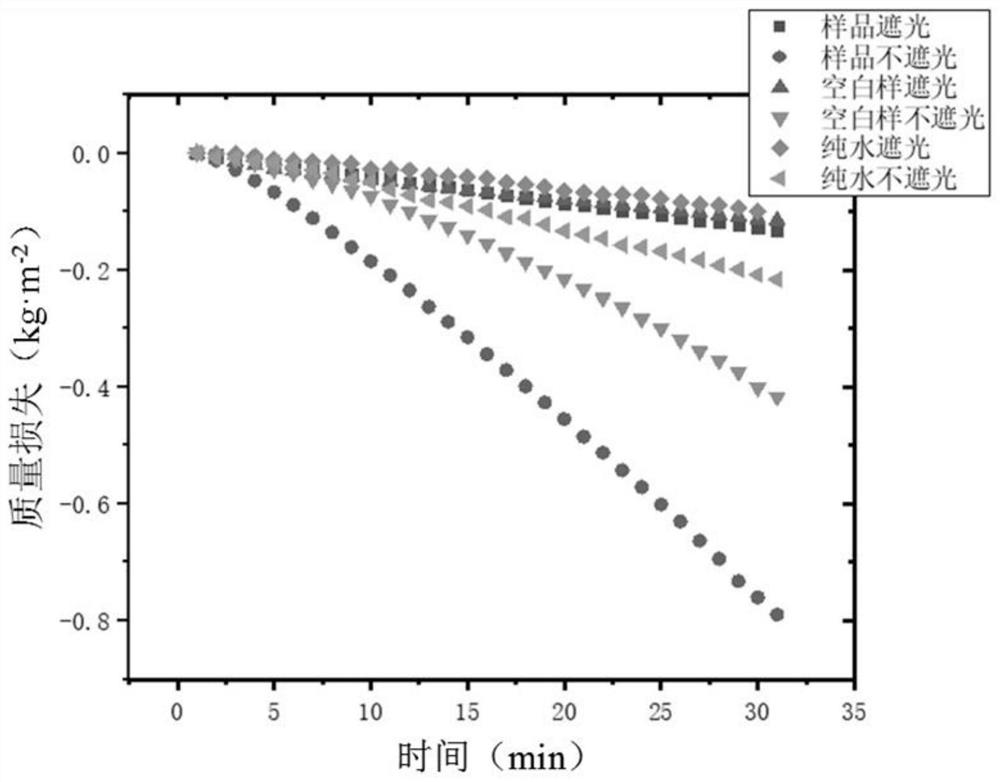

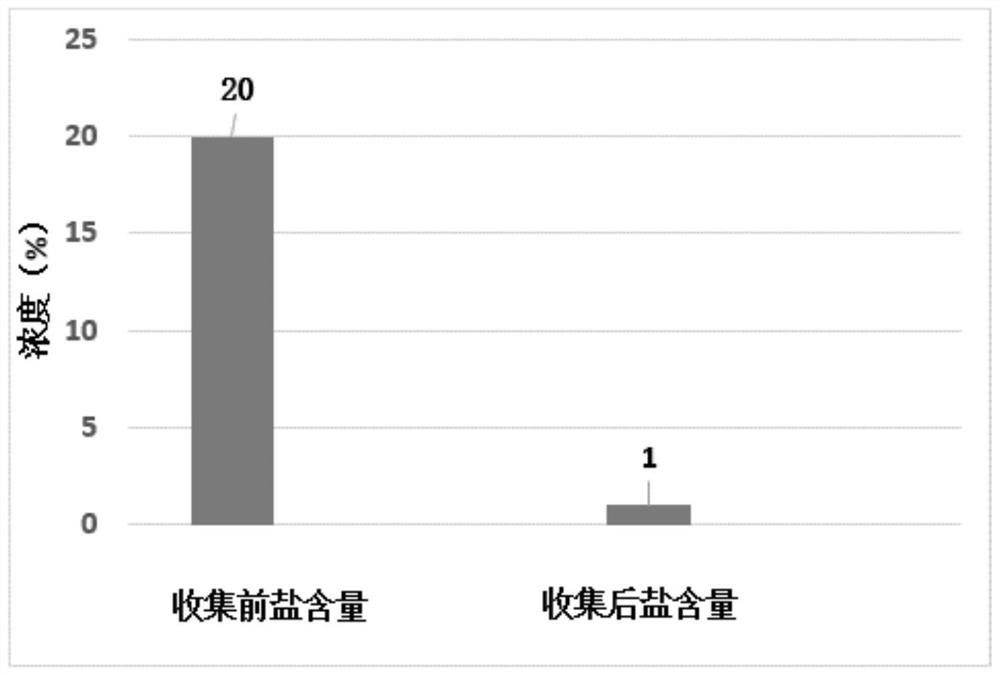

The invention provides polypyrrole-coated cattail wool-based ultra-light biomass porous foam as well as a preparation method and application thereof. Cattail wool is subjected to alkali treatment, the cattail wool is fixed and does not collapse in water through a cross-linking reaction of tannic acid and polyvinyl alcohol, and the cattail wool is freeze-dried to obtain cattail wool-based ultra-light biomass porous foam; and then, the cattail wool is coated with polypyrrole generated through in-situ polymerization to obtain the polypyrrole-coated cattail wool-based ultra-light biomass porous foam. According to the mode, the prepared cattail wool-based ultra-light biomass porous foam is stable and does not collapse, has consistent graded channels, and promotes effective coating of polypyrrole, so that the salt resistance of the foam is effectively improved, and meanwhile, the photo-thermal conversion efficiency is enhanced; and the polypyrrole-coated cattail wool-based ultra-light biomass porous foam with excellent salt resistance and high energy conversion efficiency is obtained, and is applied to a solar steam generation system as a photo-thermal material.

Owner:WUHAN TEXTILE UNIV

Preparation method of super-hydrophobic polytetrafluoroethylene fiber film

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method has the beneficial effects that the polytetrafluoroethylene film with bead-like superfine fibers is prepared and a hydrophobic surface with a multistage coarse structure is formed together; the surface water contact angle is not less than 150 degrees and the porosity is higher than 80%; the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is solved; the fibers have intact morphologies and surfaces and greatly improved strength and tenacity and can bear higher vacuum pressure.

Owner:成都百途医药科技有限公司

Preparation method of super-hydrophobic polytetrafluoroethylene fiber film

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is polyvinyl alcohol, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling.

Owner:四川百途环保材料科技有限公司 +2

Preparation method of super-hydrophobic polytetrafluoroethylene film

ActiveCN105013341AUnique structureSolve easy collapseSemi-permeable membranesFiberTemperature control

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is polyvinyl alcohol, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, increasing the temperature from a room temperature to 120-200 DEG C at a rate of 3-10 DEG C / min and insulating at 120-200 DEG C for 30-120 minutes; increasing the temperature from 120-200 DEG C to 360-400 DEG C at a rate of 2-8 DEG C / min and insulating at 360-400 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling.

Owner:四川百途环保材料科技有限公司 +2

Preparation method of polytetrafluoroethylene film

ActiveCN105013348AUnique structureSolve easy collapseSemi-permeable membranesTemperature controlFiber

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing fibers with a fiber forming carrier and sintering and is characterized by adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes. The preparation method has the beneficial effects that the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is well solved; a reticular film with bead-like superfine fibers is obtained; the fibers adhere to each other instead of being stacked out of order; the fibers have uniform morphologies, intact surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:四川百途环保材料科技有限公司 +2

Permeable brick with high performance

The invention discloses a permeable brick with high performance. A formula of the permeable brick comprises the following components in parts by mass: 10-15 parts of ceramic tile waste ceramic chip particles, 4-8 parts of titanium carbide, 10-15 parts of aluminum oxide, 10-15 parts of organic silicone resin, 13-15 parts of polyurethane resin, 7-10 parts of nanometer titanium dioxide, 20-30 parts of absolute ethyl alcohol, and 3-5 parts of a dispersing agent. The characteristic that organic silicone resin is converted into silica is used in order to solve the problem that micropore structures in the sintering process are easy to collapse, strength of permeable bricks is substantially improved, and density of the permeable brick is reduced.

Owner:苏州米颜生物科技有限公司

A kind of preparation method of superhydrophobic polytetrafluoroethylene fiber membrane

ActiveCN105013343BUnique structureSolve easy collapseDistillationNon-woven fabricsTetrafluoroethylenePorosity

The invention provides a method for preparing a polytetrafluoroethylene film, and a polytetrafluoroethylene film with beaded ultrafine fibers is prepared to form a hydrophobic surface with a multi-level rough structure; the surface water contact angle is ≥150°, and the porosity Up to 80% or more; and solve the problem of easy fiber collapse in PTFE precursor film sintering, the fiber shape and surface are intact, the strength and toughness are also greatly improved, and can withstand higher vacuum pressure.

Owner:成都百途医药科技有限公司

Preparation method of super-hydrophobic polytetrafluoroethylene film

ActiveCN105013349AUnique structureSolve easy collapseDistillationNon-woven fabricsTemperature controlTetrafluoroethylene

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is sodium alginate, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes. The preparation method has the beneficial effects that the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is well solved; a reticular film with bead-like superfine fibers is obtained; the fibers adhere to each other instead of being stacked out of order; the fibers have uniform morphologies, intact surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:四川百途环保材料科技有限公司 +2

A kind of preparation method of superhydrophobic polytetrafluoroethylene fiber membrane

ActiveCN105013342BUnique structureSolve easy collapseSemi-permeable membranesTetrafluoroethyleneTemperature control

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is polyvinyl alcohol, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling.

Owner:四川百途环保材料科技有限公司 +2

Preparation method of super-hydrophobic polytetrafluoroethylene film

ActiveCN105013345AFiber morphology and surface integrityImproves Strength and ToughnessSemi-permeable membranesMembranesVacuum pressurePTFE - Polytetrafluoroethylene

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing fibers with a fiber forming carrier and sintering and is characterized by adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, increasing the temperature from a room temperature to 120-200 DEG C at a rate of 3-10 DEG C / min and insulating at 120-200 DEG C for 30-120 minutes; increasing the temperature from 120-200 DEG C to 360-400 DEG C at a rate of 2-8 DEG C / min and insulating at 360-400 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling. The preparation method has the beneficial effects that the polytetrafluoroethylene film with bead-like superfine fibers is prepared and a hydrophobic surface with a multistage coarse structure is formed together; the surface water contact angle is not less than 150 degrees and the porosity is higher than 80%; the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is solved; the fibers have intact morphologies and surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:成都百途医药科技有限公司

Preparation method of polytetrafluoroethylene super-hydrophobic membrane

The invention provides a preparation method of a polytetrafluoroethylene membrane. The preparation method comprises spinning solution preparation, fiber formation and sintering. The preparation methodis characterized in that a fiber formation carrier and a solvent are processed into a solution, the solution is added into a polytetrafluoroethylene emulsion, the fiber formation carrier is polyacrylic acid, the solvent is water, the sintering process utilizes programmed temperature-controlled segmented continuous sintering and comprises that in a flowing atmosphere, the materials are heated fromthe room temperature to 120-200 DEG C at a heating rate of 3-10 DEG C / min, then are subjected to heat preservation at 120-200 DEG C for 30-120min, then are heated from the 120-200 DEG C to 360-400 DEG C at a heating rate of 2-8 DEG C / min and then are subjected to heat preservation at 360-400 DEG C for 5-120min, the sintering product is cooled from 360-400 DEG C to 150-200 DEG C at a rate of 3-15DEG C / min in a flowing atmosphere, is subjected to heat preservation at 150-200 DEG C for 30-120min and then is naturally cooled, and the polytetrafluoroethylene membrane has thickness of 174-222 microns. The beaded ultra-fine fiber polytetrafluoroethylene membrane is formed through the preparation method, forms a hydrophobic surface with a multi-level rough structure, has a surface water contactangle of greater than or equal to 150 degrees and porosity of 80% or more, solves the problem that in the polytetrafluoroethylene precursor membrane sintering, fibers easily collapse, has good fiber morphology and surface integrity and higher strength and toughness and can bear a certain vacuum pressure.

Owner:CHENGDU BAITU PHARM TECH CO LTD +2

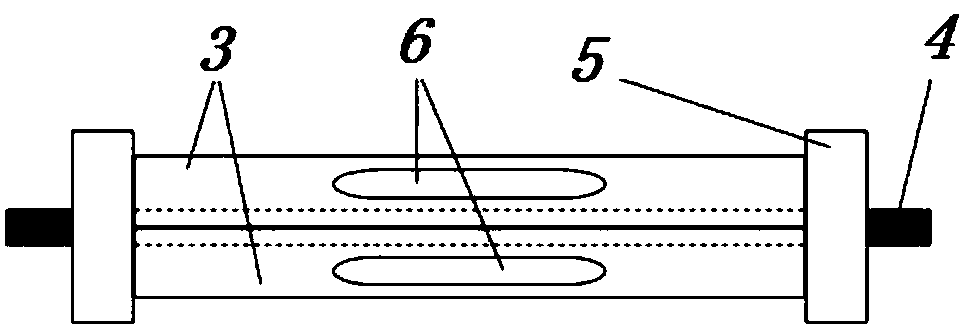

Preparation method of sewage soil infiltration device

InactiveCN102417239AImprove uniformityEasy to handleTreatment with aerobic and anaerobic processesSoil scienceWater flow

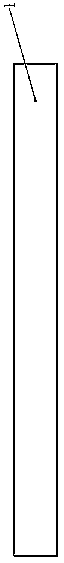

The invention relates to a preparation method of a sewage soil infiltration device, which comprises the following steps that: a plexiglass tube of which one end is closed and the other end is welded with a flange is taken, and a small sampling hole is drilled at the center of a circle of a closed end surface; a plexiglass tube of which both ends are welded with flanges is taken; a plexiglass tube of which one end is provided with an opening and the other end is welded with a flange is taken; a matrix is evenly filled in the three plexiglass tubes, and the flange end surfaces of the three plexiglass tubes are connected by bolts; and the sewage is continuously injected into the plexiglass tubes, and is sampled from the small sampling hole, and then the water outlet quality is analyzed and the water outlet quality is monitored. In the preparation method of the sewage soil infiltration device, the problems that the matrix is unevenly filled, a matrix layer collapses and the water flow is short-circuited in the traditional soil column simulation soil percolation process, can be solved, and the treatment effect of the sewage is improved.

Owner:SHENYANG UNIV

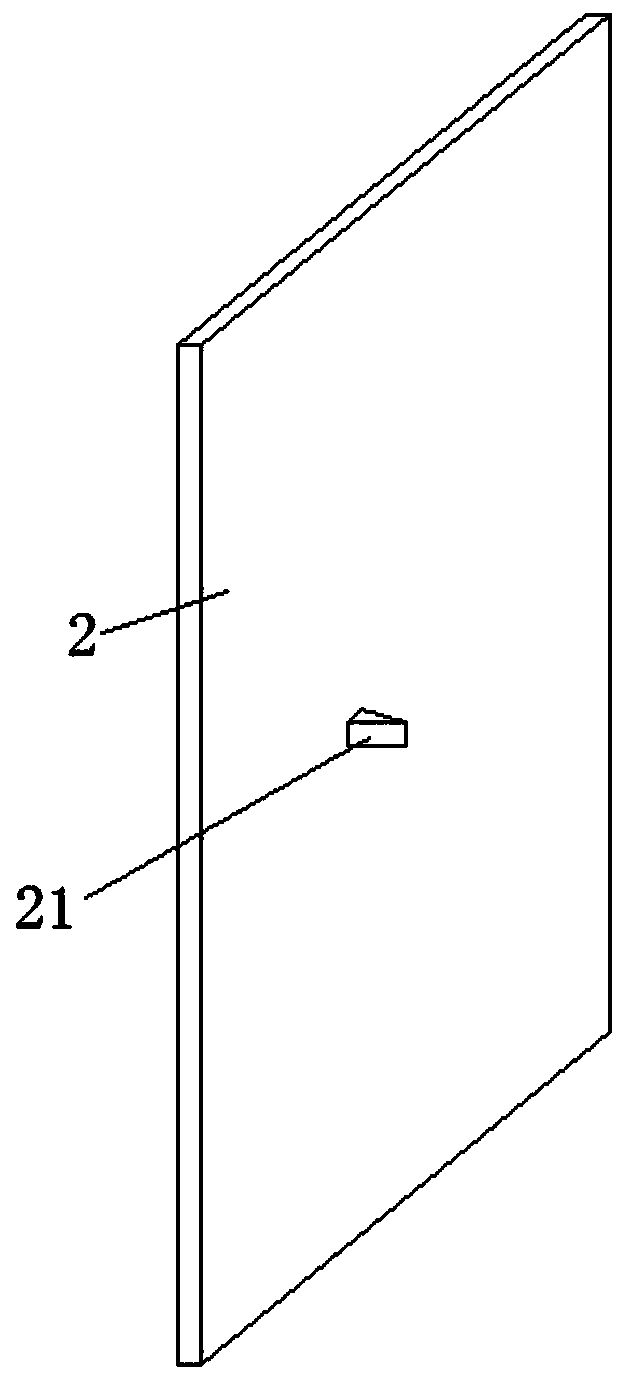

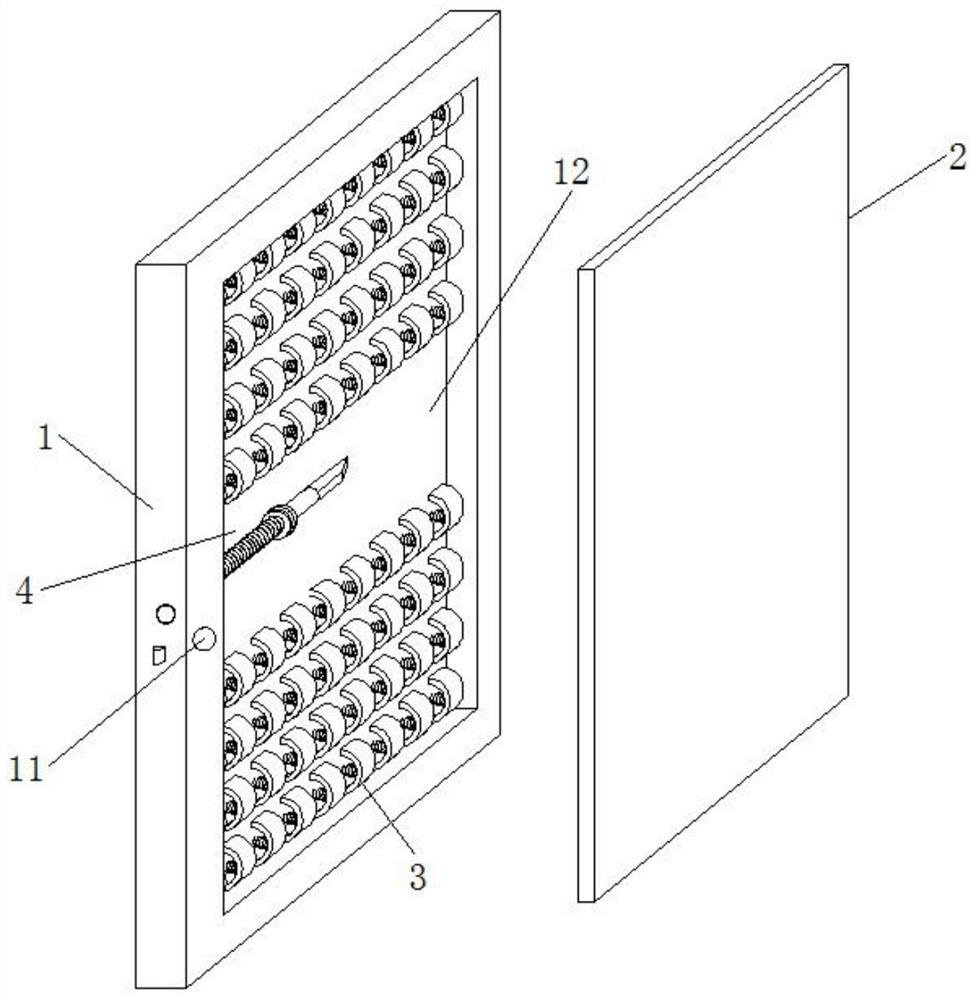

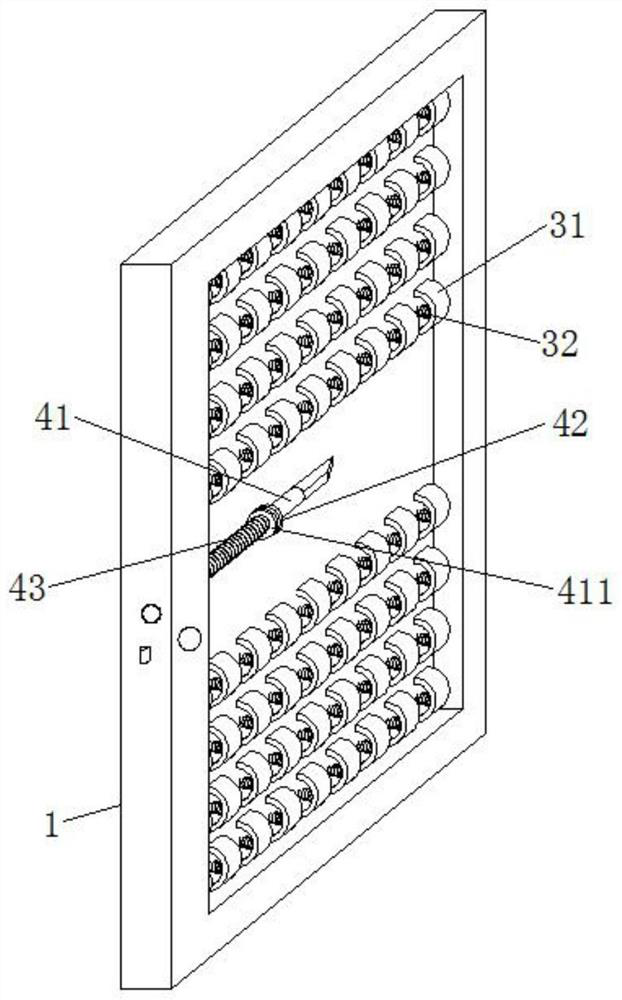

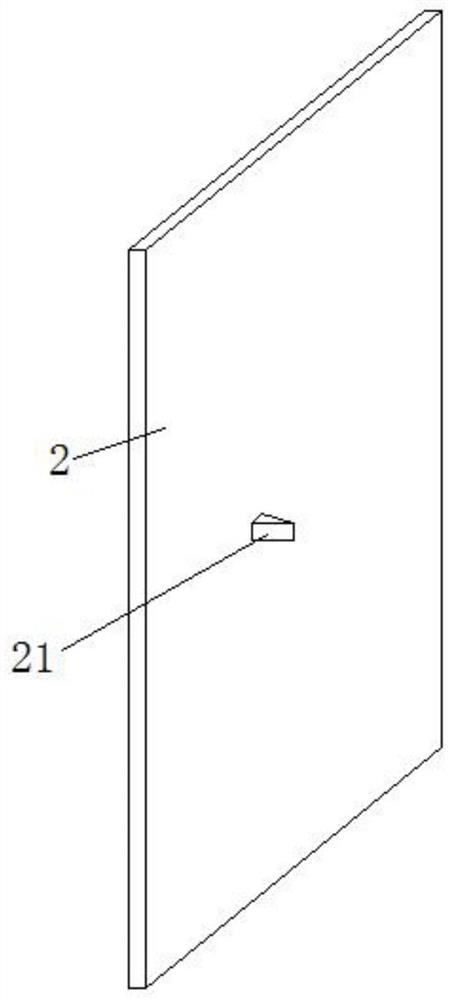

Wooden door with anti-collision structure

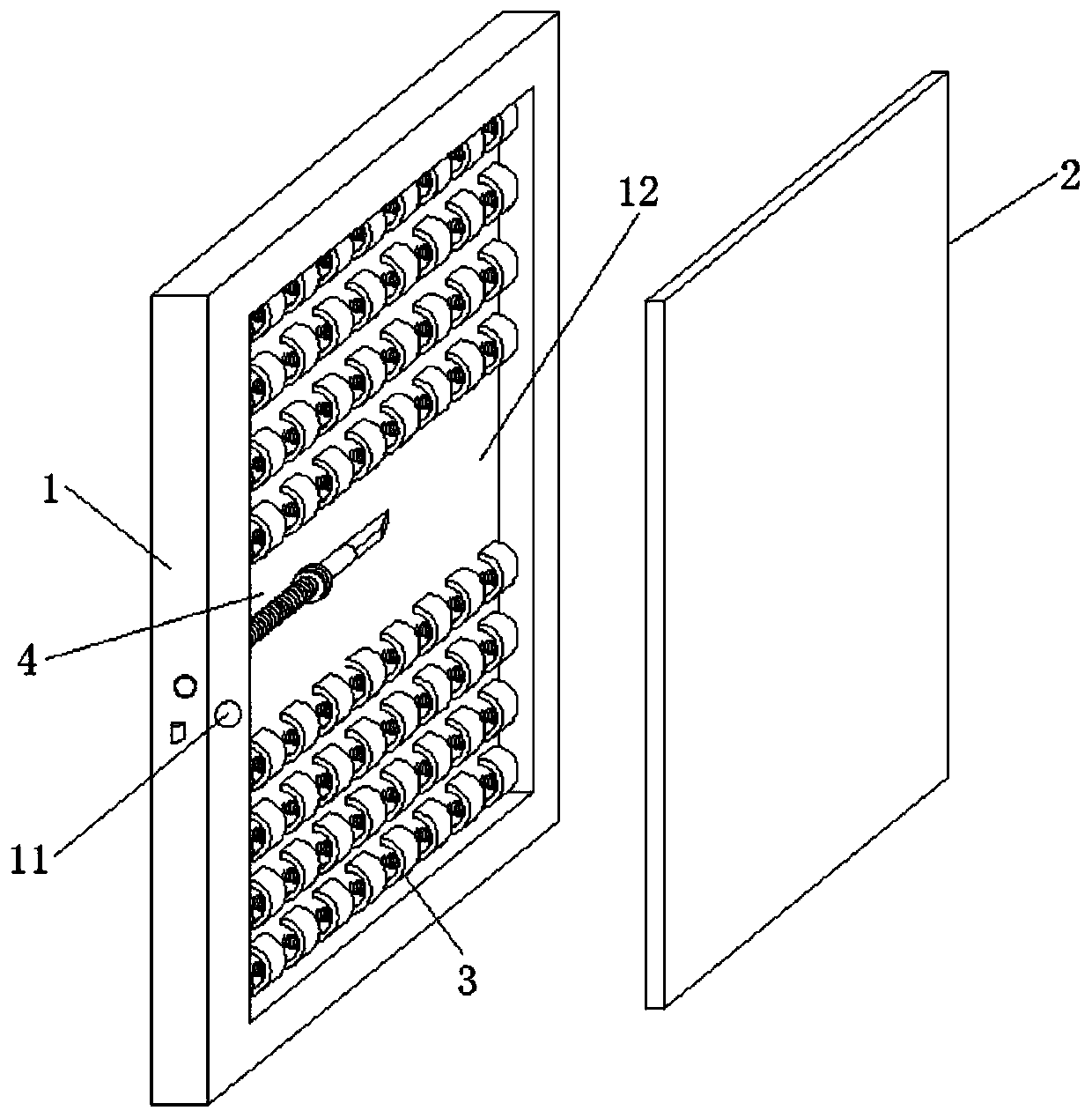

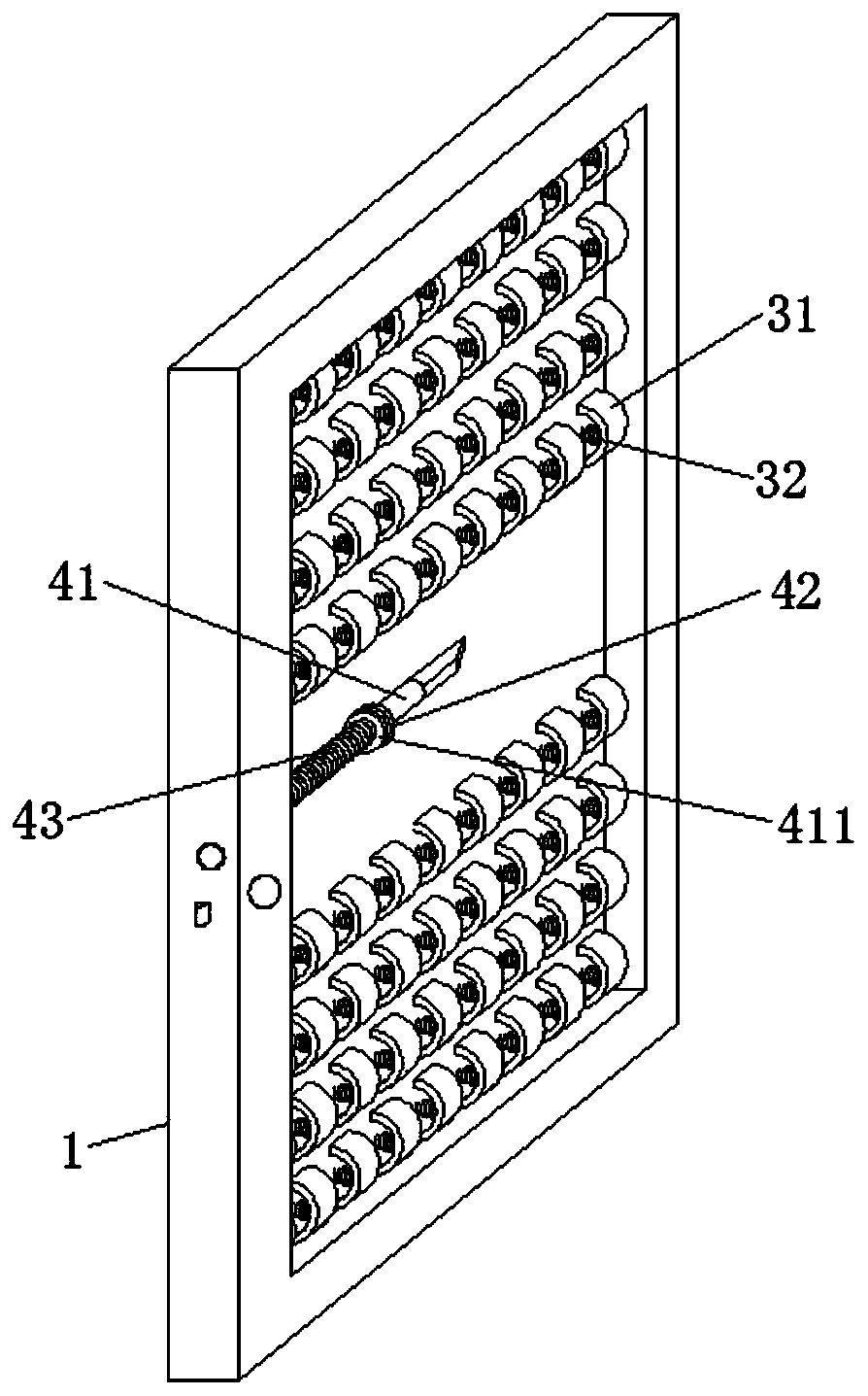

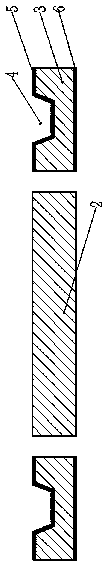

ActiveCN109723332ASolve easy collapseAvoid destructionBuilding locksDoor leavesEngineeringSurface plate

The invention discloses a wooden door with an anti-collision structure. The wooden door comprises a door body and a surface plate. A mechanical lock is arranged at the locking end of the door body, agroove is formed in the outer side face of the door body, the surface plate is embedded into the groove, a clearance exists between the surface plate and the bottom face of the groove, and buffering set structures are arranged on the upper portion and the lower portion in the clearance between the surface plate and the bottom face of the groove. The buffering set structures are formed by evenly arranging a plurality of buffering structures, one end of each buffering structure is fixed to the inner bottom face of the groove, and the other end of each buffering structure is fixed to the inner side face of the surface plate. The wooden door with the anti-collision structure is not likely to be cracked up, and can be used as a security door.

Owner:佛山市步园家具有限公司

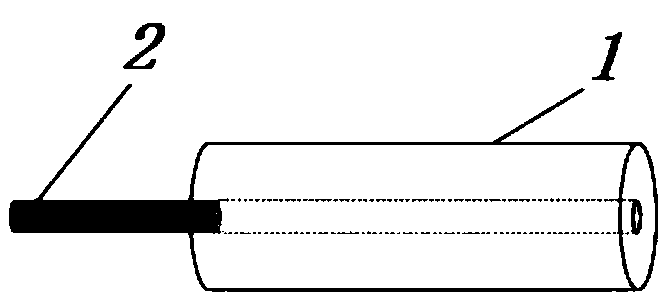

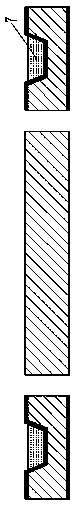

Preparation method for easy-suturing high-simulation tissue engineering neural repair scaffold

InactiveCN108714247ASolve problemsSolve the problem of nerve stump suturingTissue regenerationProsthesisFreeze-dryingAcetic acid solution

The invention relates to a preparation method for an easy-suturing high-simulation tissue engineering neural repair scaffold. The preparation method comprises a step of preparing suspension, a step ofpreparing an array micro-pipe inner core, a step of preparing collagen outer skin and a step of cutting and assembling. The step of preparing the suspension comprises the following steps: weighing collagen and chitosan, after uniformly mixing, and dissolving in acetic acid solution. The step of preparing the array micro-pipe inner core comprises the following steps: enabling the suspension to beinjected in a mould, inserting a temperature conducting rod, immerging in liquid nitrogen and performing gradient cooling, freeze-drying, crosslinking, washing, freeze-storing and freeze-drying again.The step of preparing the collagen outer skin comprises the following steps: enabling the suspension to be injected in the mould, washing, drying, crosslinking, washing again, freeze-storing and drying again. The step of cutting and assembling comprises the following steps: cutting and assembling. The provided rational preparation method is capable of solving problems of an existing scaffold product that an internal three-dimensional structure is lacked and the collapse is easy, and solving a problem that the parallel and level tail end of the porous scaffold is not easily sutured.

Owner:沈阳尚贤再生医学科技股份有限公司

Semiconductor laser welding method and semiconductor laser welding structure

InactiveCN109967872AAchieve protectionPrevent oxidationLaser beam welding apparatusHigh probabilityOptoelectronics

The invention provides a semiconductor laser welding method and a semiconductor laser welding structure. The invention uses laser to activate metal complexes or melt solderable metal particles, so that the protection of solder is realized, the oxidation of the solder is prevented and the wettability of the solder can be ensured. The semiconductor laser welding method and a semiconductor laser welding structure can solve the problem of weak welding strength of a welding layer, and the problems of high probability of collapse and poor wettability of a welding ball.

Owner:苏州福唐智能科技有限公司

A kind of preparation method of polytetrafluoroethylene superhydrophobic film

ActiveCN105013345BUnique structureSolve easy collapseMembranesSemi-permeable membranesPorositySurface water

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing fibers with a fiber forming carrier and sintering and is characterized by adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, increasing the temperature from a room temperature to 120-200 DEG C at a rate of 3-10 DEG C / min and insulating at 120-200 DEG C for 30-120 minutes; increasing the temperature from 120-200 DEG C to 360-400 DEG C at a rate of 2-8 DEG C / min and insulating at 360-400 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling. The preparation method has the beneficial effects that the polytetrafluoroethylene film with bead-like superfine fibers is prepared and a hydrophobic surface with a multistage coarse structure is formed together; the surface water contact angle is not less than 150 degrees and the porosity is higher than 80%; the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is solved; the fibers have intact morphologies and surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:成都百途医药科技有限公司

A wooden door with an anti-collision structure

ActiveCN109723332BSolve easy collapseAvoid destructionBuilding locksDoor leavesStructural engineeringMechanical engineering

Owner:佛山市步园家具有限公司

A kind of preparation method of superhydrophobic polytetrafluoroethylene film

ActiveCN105013349BUnique structureSolve easy collapseDistillationNon-woven fabricsTetrafluoroethyleneTemperature control

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is sodium alginate, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes. The preparation method has the beneficial effects that the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is well solved; a reticular film with bead-like superfine fibers is obtained; the fibers adhere to each other instead of being stacked out of order; the fibers have uniform morphologies, intact surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:四川百途环保材料科技有限公司 +2

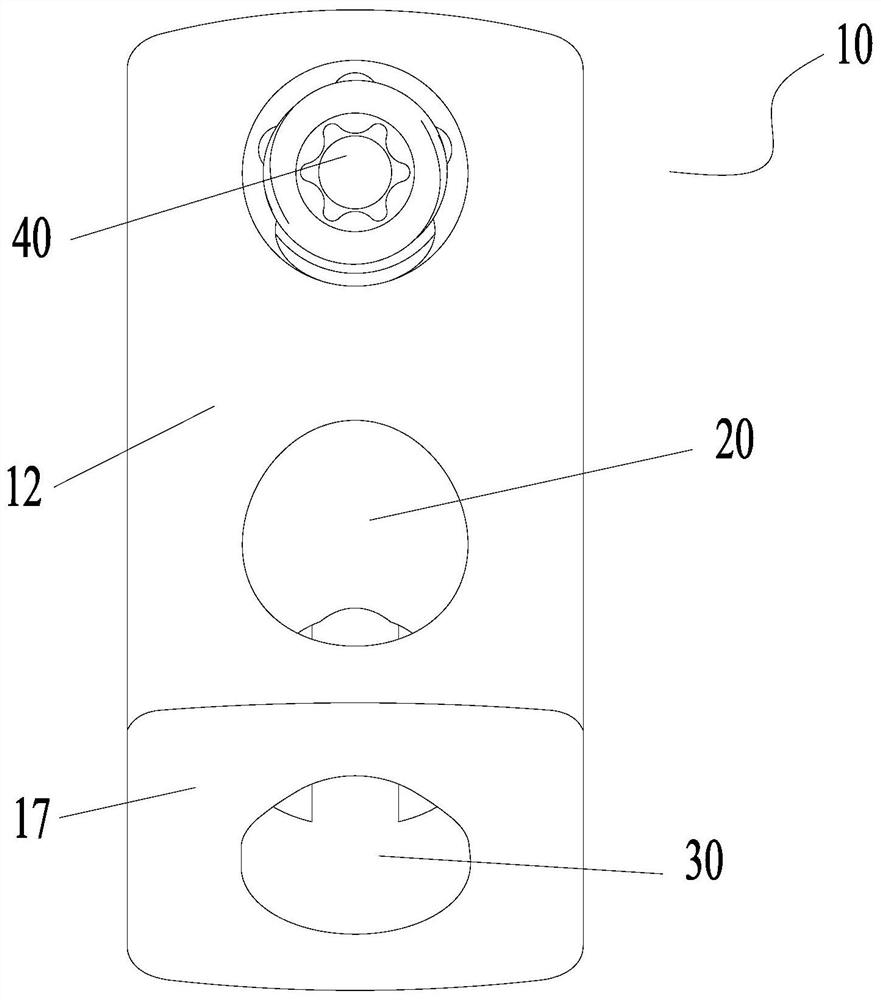

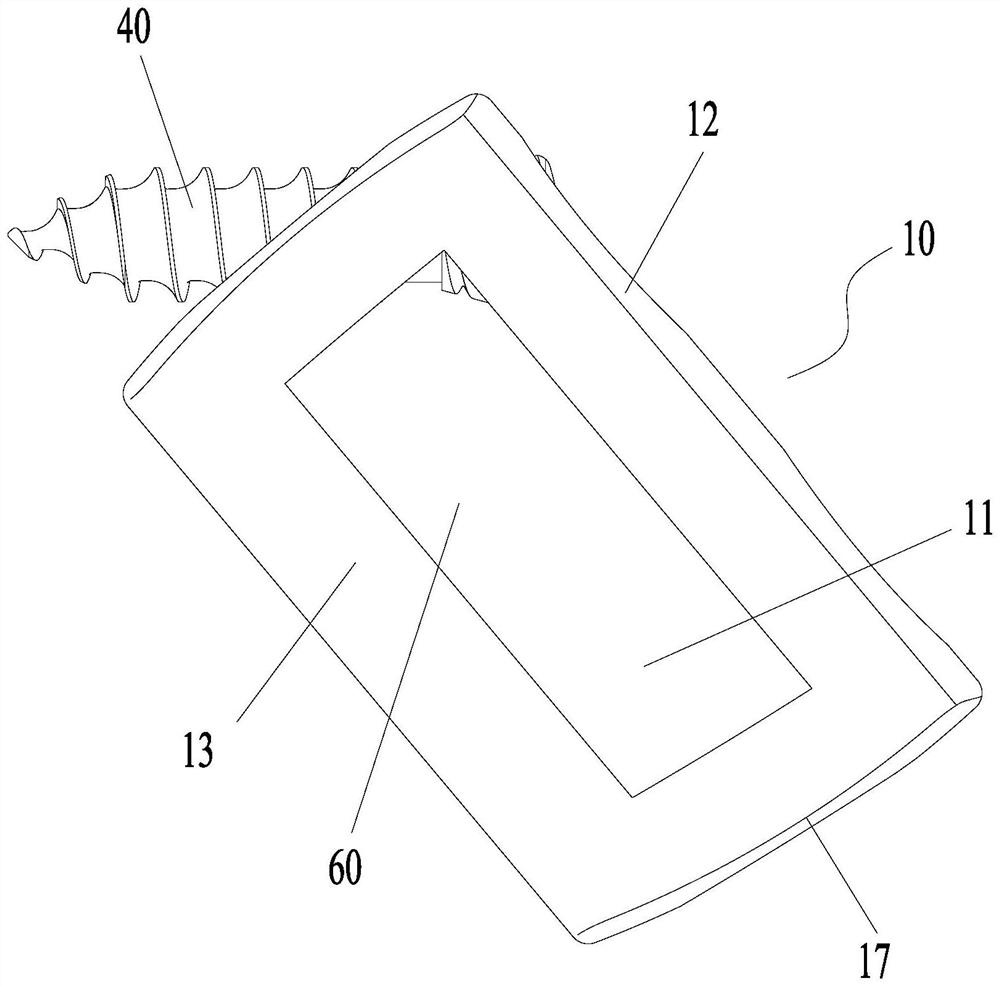

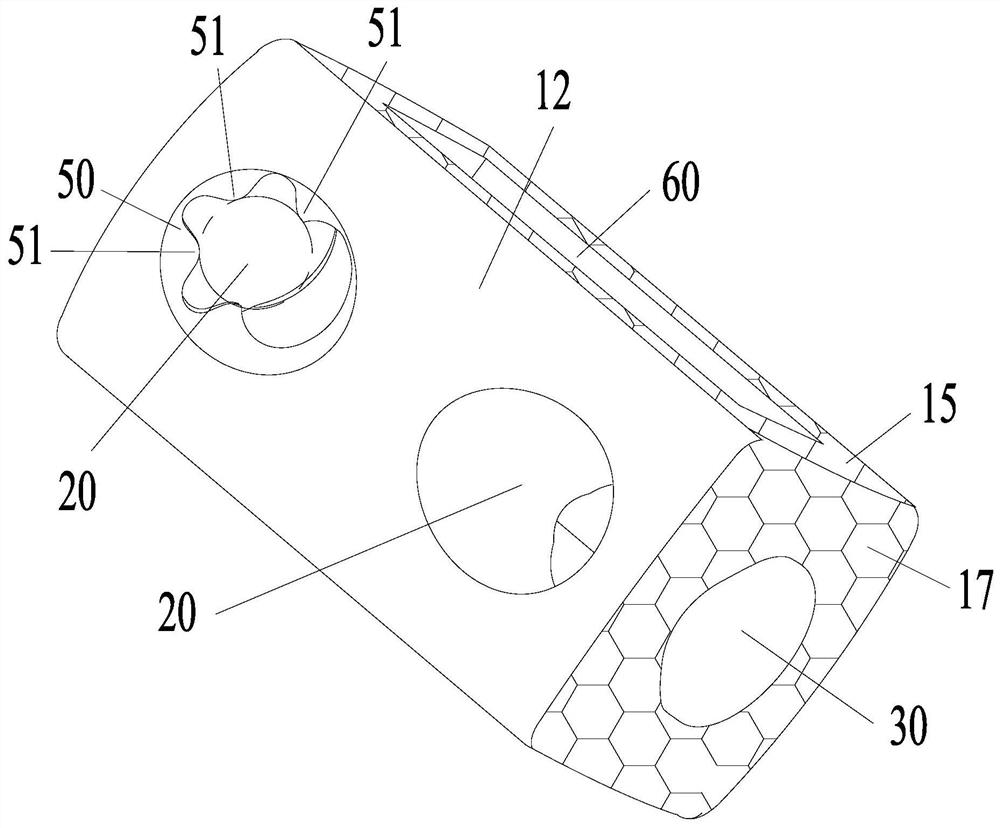

Vertebral prosthesis

InactiveCN112773577APrevent collapseSolve easy collapseJoint implantsSpinal implantsBone graftingBiomedical engineering

The invention provides a vertebral prosthesis which is characterized in that a bone grafting space is arranged in a base body, and the base body is mounted in a vertebral body; a connecting hole is formed in the side wall of the base body and communicated with the bone grafting space, and the connecting hole is exposed out of the vertebral body; a bone grafting hole is formed in the end wall of the base body and communicated with the bone grafting space; a fastener penetrates in from the connecting hole and penetrates out from the bone grafting hole; and a connecting part which is matched with the fastener in a limiting manner is arranged in the connecting hole. According to the technical scheme, the problem that in the prior art, a vertebral body is prone to collapse is effectively solved.

Owner:BEIJING AKEC MEDICAL

A high-performance permeable brick

The invention discloses a permeable brick with high performance. A formula of the permeable brick comprises the following components in parts by mass: 10-15 parts of ceramic tile waste ceramic chip particles, 4-8 parts of titanium carbide, 10-15 parts of aluminum oxide, 10-15 parts of organic silicone resin, 13-15 parts of polyurethane resin, 7-10 parts of nanometer titanium dioxide, 20-30 parts of absolute ethyl alcohol, and 3-5 parts of a dispersing agent. The characteristic that organic silicone resin is converted into silica is used in order to solve the problem that micropore structures in the sintering process are easy to collapse, strength of permeable bricks is substantially improved, and density of the permeable brick is reduced.

Owner:苏州米颜生物科技有限公司

Polypyrrole-coated cattail velvet-based ultra-light biomass porous foam and its preparation method and application

ActiveCN113321939BImprove mechanical propertiesImprove salt toleranceGeneral water supply conservationSeawater treatmentPolymer sciencePolypyrrole

Owner:WUHAN TEXTILE UNIV

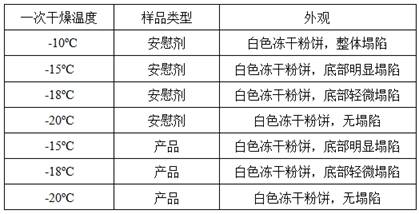

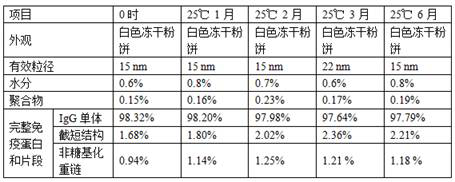

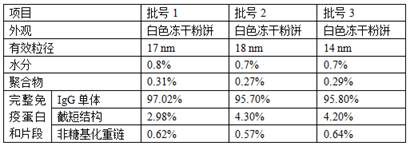

Preparation method of infliximab freeze-dried preparation for injection

PendingCN114028563ASolve easy collapseQuality improvementPowder deliveryAntipyreticSucroseFreeze-drying

The invention discloses a preparation method of an infliximab freeze-dried preparation for injection. Before freeze-drying, a liquid medicine contains the following components: infliximab with the concentration of 20 mg / mL, sodium phosphate with the concentration of 10 mM, polysorbate 80 with the concentration of 0.1 mg / mL and cane sugar with the concentration of 100 mg / mL; feeding the liquid medicine to a freeze dryer, and keeping a freeze drying chamber at 5 DEG C for 2 hours; cooling to -50 - -40 DEG C, and keeping for 5-8 hours; vacuumizing and sublimation drying: heating to -20 - -15 DEG C for the first time and keeping for 50-70 hours, heating to -10-0 DEG C for the second time and keeping for 8-10 hours; desorption: raising the temperature to 20-30 DEG C, keeping the temperature for 10-15 hours, reducing the temperature to 5 DEG C, and keeping the temperature for 20 minutes. The polymer content is reduced, the risk of immunogenicity of the product is reduced, the collapse problem of the product in the freeze-drying process is solved, and a freeze-drying preparation product with excellent quality is produced.

Owner:KINDOS PHARM CO LTD +1

A kind of preparation method of superhydrophobic polytetrafluoroethylene film

ActiveCN104998557BUnique structureSolve easy collapseSemi-permeable membranesMembranesPolymer scienceSolvent

The invention provides a production method of a super-hydrophobic polytetrafluoroethylene membrane. The method comprises the steps of preparing a spinning solution, producing fibers, and sintering, wherein a fiber forming carrier and a solvent are adopted to prepare a solution, a polytetrafluoroethylene emulsion is added, the fiber forming carrier is polyacrylic acid, and the solvent is water; and the sintering step adopts temperature programmed control sectional continuous sintering, and is characterized by carrying out heat insulation in flowing atmosphere at 90-120DEG C for 30-120min, heating to 260-300DEG C from 90-120DEG C at a rate of 3-10DEG C / min, carrying out heat insulation at 260-300DEG C for 30-120min, heating to 370-390DEG C from 260-300DEG C at a rate of 2-8DEG C / min, and carrying out heat insulation at 370-390DEG C for 5-120min. The method well solves the problem of easy collapsing of fibers in the sintering process of a polytetrafluoroethylene precursor membrane, and allows the beaded ultrafine fiber netted membrane, disordered stacking between fibers becomes mutual adhesion, and the fibers have the characteristics of uniform form, complete surface, and greatly improved strength and toughness, and can bear a certain vacuum pressure.

Owner:成都百途医药科技有限公司

Preparation method of super-hydrophobic polytetrafluoroethylene film

ActiveCN107684836AUnique structureSolve easy collapseMembranesSemi-permeable membranesTemperature controlTetrafluoroethylene

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method of the polytetrafluoroethylene film comprises the steps of preparing a spinning solution, making afiber and sintering. The preparation method is characterized in that a fiber forming carrier and a solvent are prepared into a solution, the solution is added into a polytetrafluoroethylene emulsion,the fiber forming carrier is gelatin, and the solvent is water; sectional continuous sintering is adopted through programmed temperature control, the heat is preserved at the temperature of 90-120 DEG C for 30-120 minutes under the flowing atmosphere, the temperature is raised from 90-120 DEG C to 260-300 DEG C at the speed of 3-10 DEG C per minute, and the heat is preserved at the temperature of260-300 DEG C for 30-120 minutes; the temperature is raised from 260-300 DEG C to 370-390 DEG C at the speed of 2-8 DEG C per minute, and the heat is preserved at the temperature of 370-390 DEG C for5-120 minutes; and the thickness of the polytetrafluoroethylene film is 170-212 [mu]m. The preparation method excellently solves the problem that a fiber collapses easily in the sintering of a polytetrafluoroethylene precursor film, a beaded superfine fiber network film is obtained, the state of the fibers is changed from disordered stacking to mutual adhesion, the fiber morphology is uniform, the surface is complete, the strength and the tenacity are also greatly improved, and the film can bear certain vacuum pressure.

Owner:成都百途医药科技有限公司 +2

A kind of preparation method of polytetrafluoroethylene superhydrophobic film

ActiveCN105013351BUnique structureSolve easy collapseSemi-permeable membranesPorosityPolymer science

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing a spinning solution, preparing fibers and sintering and is characterized by adding polytetrafluoroethylene emulsion after preparing a solution with a fiber forming carrier and a solvent, wherein the fiber forming carrier is gelatin, and the solvent is water; adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, increasing the temperature from a room temperature to 120-200 DEG C at a rate of 3-10 DEG C / min and insulating at 120-200 DEG C for 30-120 minutes; increasing the temperature from 120-200 DEG C to 360-400 DEG C at a rate of 2-8 DEG C / min and insulating at 360-400 DEG C for 5-120 minutes; carrying out cooling treatment after sintering: in the flowing atmospheres, reducing the temperature from 360-400 DEG C to 150-200 DEG C at a rate of 3-15 DEG C / min, insulating at 150-200 DEG C for 30-120 minutes and then carrying out natural cooling. The preparation method has the beneficial effects that the polytetrafluoroethylene film with bead-like superfine fibers is prepared and a hydrophobic surface with a multistage coarse structure is formed together; the surface water contact angle is not less than 150 degrees and the porosity is higher than 80%; the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is solved; the fibers have intact morphologies and surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:四川百途环保材料科技有限公司 +2

A kind of preparation method of polytetrafluoroethylene film

ActiveCN105013348BUnique structureSolve easy collapseSemi-permeable membranesTemperature controlFiber

The invention provides a preparation method of a polytetrafluoroethylene film. The preparation method comprises the steps of preparing fibers with a fiber forming carrier and sintering and is characterized by adopting multistep continuous sintering through program temperature control, and in flowing atmospheres, insulating at 90-120 DEG C for 30-120 minutes, increasing the temperature from 90-120 DEG C to 260-300 DEG C at a rate of 3-10 DEG C / min and insulating at 260-300 DEG C for 30-120 minutes; increasing the temperature from 260-300 DEG C to 370-390 DEG C at a rate of 2-8 DEG C / min and insulating at 370-390 DEG C for 5-120 minutes. The preparation method has the beneficial effects that the problem that fibers are easy to collapse during sintering of a polytetrafluoroethylene precursor film is well solved; a reticular film with bead-like superfine fibers is obtained; the fibers adhere to each other instead of being stacked out of order; the fibers have uniform morphologies, intact surfaces and greatly improved strength and tenacity and can bear a certain vacuum pressure.

Owner:四川百途环保材料科技有限公司 +2

A kind of preparation method of polytetrafluoroethylene superhydrophobic film

ActiveCN105013346BUnique structureSolve easy collapseSemi-permeable membranesPorosityPolymer science

The invention provides a preparation method of polytetrafluoroethylene film, which includes dosing of spinning solution, fiber making and sintering, and is characterized in that polytetrafluoroethylene emulsion is added after the fiber-forming carrier and solvent are prepared into a solution, and the fiber-forming carrier It is sodium alginate, the solvent is water; the sintering adopts the program temperature control segmental continuous sintering, under the flow atmosphere, the temperature is raised from room temperature to 120 ℃ ~ 200 ℃ at a rate of 3 ~ 10 ℃ / min, and the temperature is kept at 120 ℃ ~ 200 ℃ 30-120min; heat up from 120-200°C to 360-400°C at a rate of 2-8°C / min, keep warm at 360°C-400°C for 5-120min; cool after sintering, the cooling is in a flowing atmosphere Cool down from 360-400°C to 150-200°C at a rate of 3-15°C / min, keep warm at 150-200°C for 30-120min, and then cool naturally. The present invention has produced the polytetrafluoroethylene film with beaded superfine fibers, forming a hydrophobic surface with a multi-level rough structure together; the surface water contact angle is more than or equal to 150°, and the porosity is as high as more than 80%; and solves the problem of polytetrafluoroethylene In the sintering of the precursor film, the fiber is easy to collapse, the shape and surface of the fiber are intact, the strength and toughness are also greatly improved, and it can withstand a certain vacuum pressure.

Owner:成都百途医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com