Semiconductor laser welding method and semiconductor laser welding structure

A laser welding and semiconductor technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of solder ball collapse, easy oxidation of solder balls, low bonding strength, etc., to ensure wettability, solve easy problems. Collapse, achieve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] see Figure 1-7 , semiconductor laser welding method of the present invention, comprises the following steps;

[0031] 1) see figure 1 , providing a metal plate 1, which has a front side and a back side; the metal plate is a copper plate or an aluminum plate, and its thickness is 0.1-1mm;

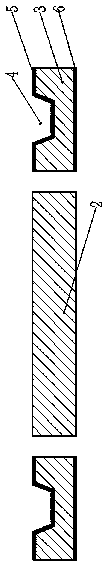

[0032] 2) see figure 2 , etching the metal plate 1 to form a base island portion 2 and a pin portion 3, and forming a groove 4 on the front surface of the pin portion;

[0033] 3) forming a nickel plating layer 5 / 6 on the front and back of the pin part 3, the nickel plating layer 5 covering the side wall and bottom surface of the groove 4;

[0034] 4) see image 3 , filling the solidified solder 7 in the groove 4;

[0035] 5) see Figure 4 , wrapping the base island part 2 and the pin part 3 with a resin 8, the resin 8 completely covers the solder 7, and metal solderable particles are mixed in the resin 8;

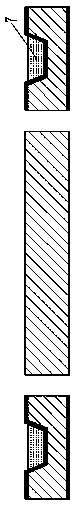

[0036] 6) Using a laser 9 to make the resin form an opening 10 and m...

no. 2 example

[0041] The semiconductor laser welding method of the second embodiment of the present invention comprises the following steps;

[0042] 1) see figure 1 , providing a metal plate 1, which has a front side and a back side; the metal plate is a copper plate or an aluminum plate, and its thickness is 0.1-1mm;

[0043] 2) see figure 2 , etching the metal plate 1 to form a base island portion 2 and a pin portion 3, and forming a groove 4 on the front surface of the pin portion;

[0044] 3) forming a nickel plating layer 5 / 6 on the front and back of the pin part 3, the nickel plating layer 5 covering the side wall and bottom surface of the groove 4;

[0045] 4) see image 3 , filling the solidified solder 7 in the groove 4;

[0046] 5) see Figure 4 , wrapping the base island part 2 and the pin part 3 with a resin 8, the resin 8 completely covers the solder 7, and a metal complex is mixed in the resin 8;

[0047] 6) Using a laser 9 to make the resin form an opening 10 and mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com