Production method of super-hydrophobic polytetrafluoroethylene membrane

A technology of polytetrafluoroethylene film and polytetrafluoroethylene, which is applied in the field of preparation of hydrophobic film materials, can solve the problems of only focusing on the removal of fiber-forming templates, and achieve the effects of uniform fiber shape, intact surface, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

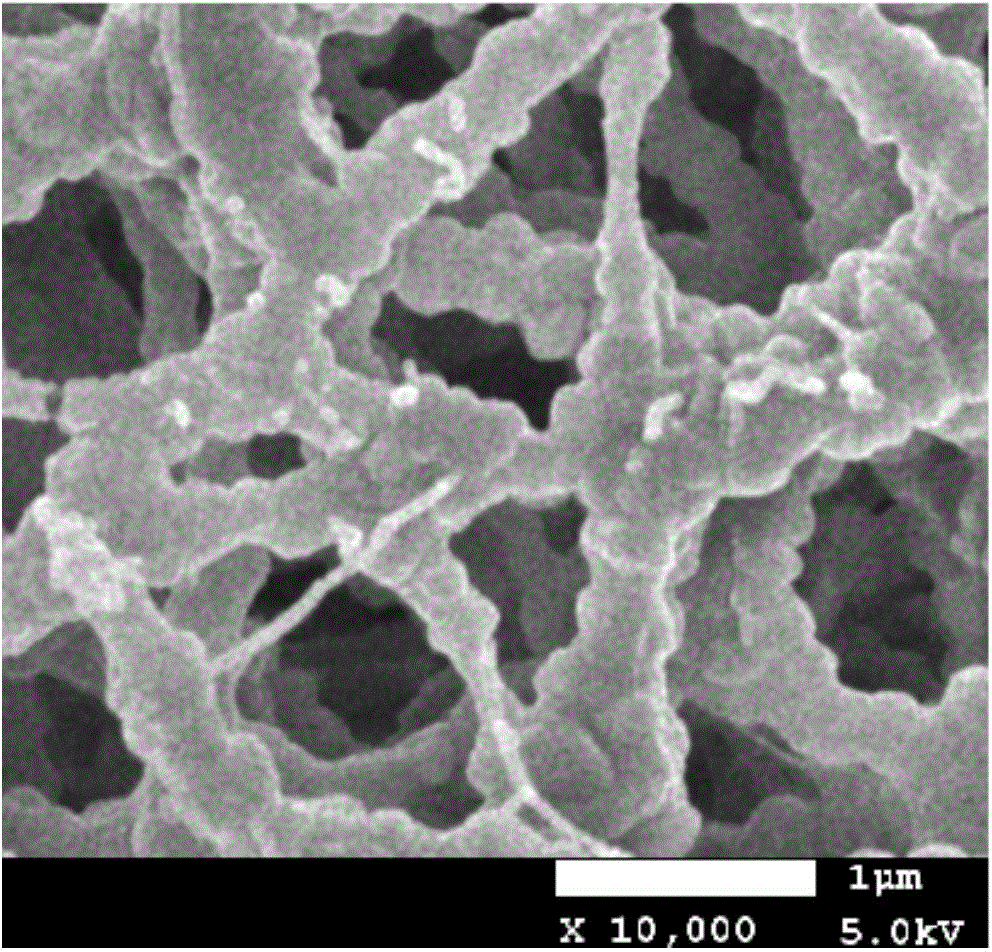

Embodiment 1

[0028] The polytetrafluoroethylene emulsion with a solid content of 60% is added dropwise to a polyacrylic acid aqueous solution with a mass fraction of 15%, and stirred evenly to prepare a spinning solution. Then the polytetrafluoroethylene precursor film was fabricated by electrospinning method. Winding on a cylindrical support mold with a diameter of 5cm, winding 5 layers, and sending it to a tube furnace with nitrogen gas, the temperature of the sintering process is controlled by a program, and the temperature is raised from room temperature to 110°C at 10°C / min, kept at 110°C for 90min, and at 7°C / min The heating rate is raised from 110°C to 290°C, kept at 290°C for 100 minutes, raised from 290°C to 380°C, the heating rate is 6°C / min, and kept at 60 minutes. After cooling, take it out and pull out the cylindrical support mold to obtain a cylindrical polytetrafluoroethylene membrane with a thickness of 165 μm, which can be cut to obtain a flat porous membrane. The membra...

Embodiment 2

[0030] The polytetrafluoroethylene emulsion with a solid content of 60% was added dropwise to an aqueous polyacrylic acid solution with a mass fraction of 8%, and stirred evenly to prepare a spinning solution. Then the polytetrafluoroethylene precursor film was fabricated by electrospinning method. Winding on a cylindrical support mold with a diameter of 5cm, winding 5 layers, and sending it to a tube furnace with nitrogen gas. The temperature of the sintering process is controlled by a program. / min The heating rate is raised from 90°C to 260°C, the temperature is kept at 260°C for 120 minutes, the temperature is raised from 260°C to 375°C, the heating rate is 8°C / min, and the temperature is kept for 115 minutes. After cooling, take it out and pull out the cylindrical support mold to obtain a cylindrical polytetrafluoroethylene membrane with a thickness of 160um, which can be cut to obtain a flat porous membrane. The membrane has a hydrophobic contact angle of 156°, a porosi...

Embodiment 3

[0032] The polytetrafluoroethylene emulsion with a solid content of 60% was added dropwise to a polyacrylic acid aqueous solution with a mass fraction of 6%, and stirred evenly to prepare a spinning solution. Then the polytetrafluoroethylene precursor film was fabricated by electrospinning method. Winding on a cylindrical support mold with a diameter of 5cm, winding 5 layers, and sending it to a tube furnace with nitrogen gas. The temperature of the sintering process is controlled by a program. / min The heating rate is raised from 100°C to 275°C, the temperature is kept at 275°C for 110 minutes, the temperature is raised from 275°C to 380°C, the heating rate is 3°C / min, and the temperature is kept for 90 minutes. After cooling, take it out and pull out the cylindrical support mold to obtain a cylindrical polytetrafluoroethylene membrane with a thickness of 166um, which can be cut to obtain a flat porous membrane. The membrane has a hydrophobic contact angle of 163°, a porosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hydrophobic contact angle | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com