PU film and fabric lamination equipment and method

A technology for laminating equipment and fabrics, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of unimproved waterproof, anti-wrinkle and other properties, poor overall performance, poor adhesion, etc. Strong adhesion, improved waterproofness, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a PU film cloth pressing method based on the above-mentioned PU film cloth pressing equipment, comprising the following steps:

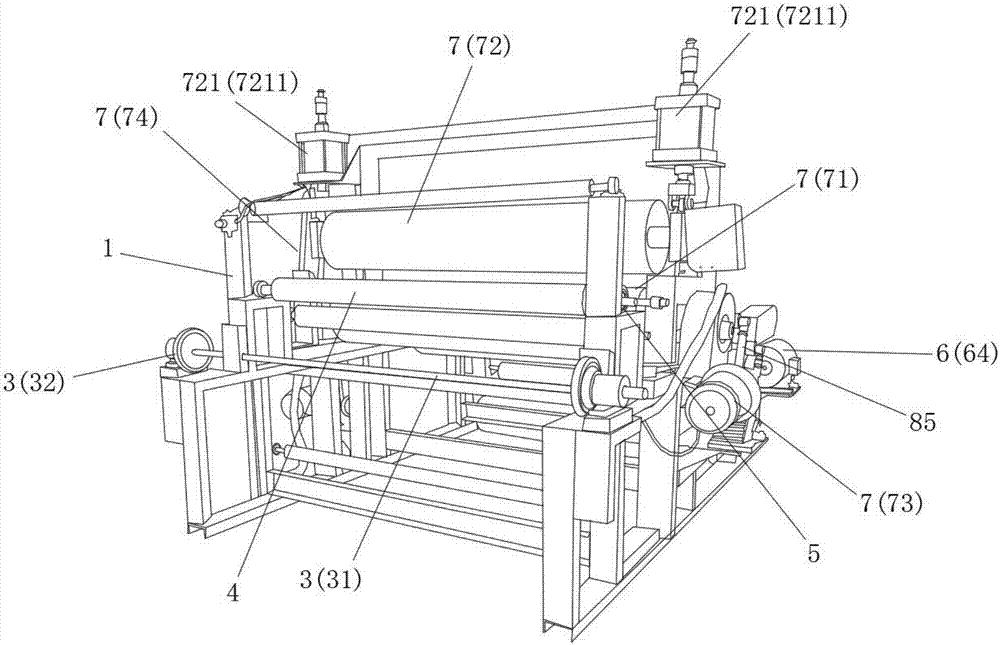

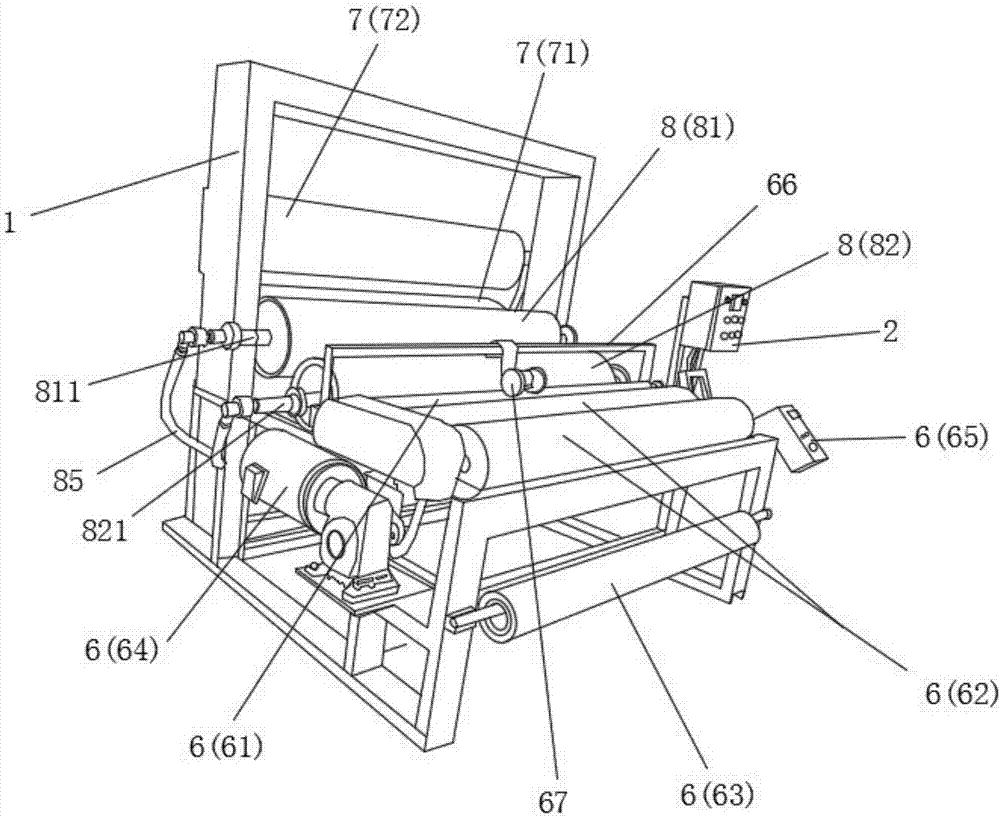

[0042] (1) The PU film cloth covered with PU film is wound on the feeding mechanism 3, and the PU film cloth passes through the guide roller 4 and the flattening roller 5 successively, and the PU film cloth is guided and flattened successively, keeping The PU film cloth moves smoothly;

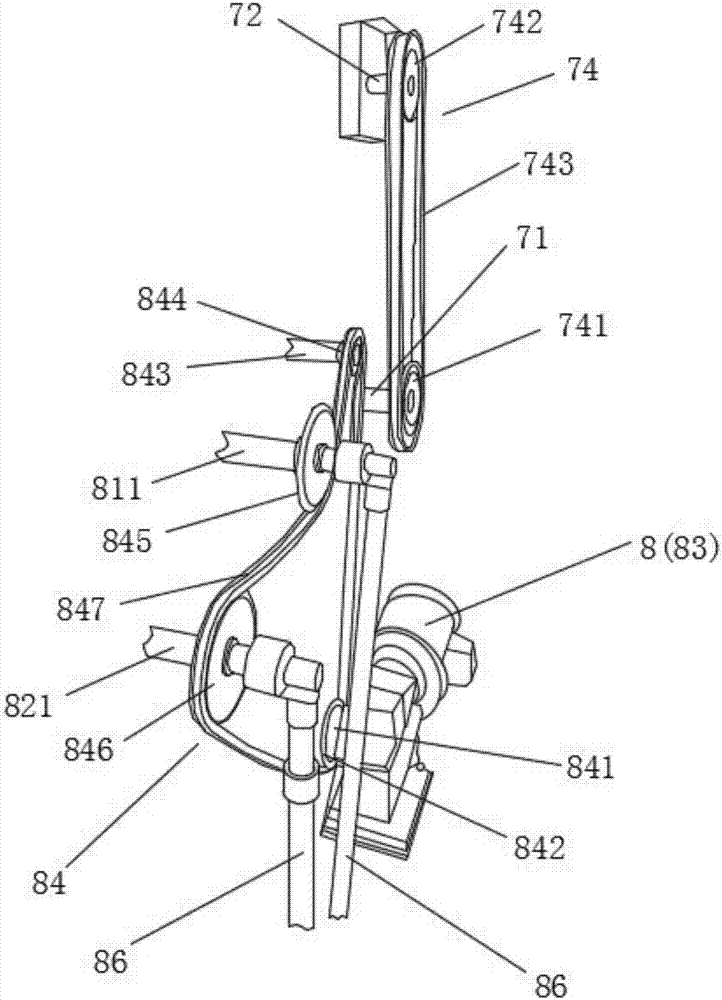

[0043] (2) Next, the PU film cloth enters between the silicone roller 71 and the heating roller 72 of the pressing mechanism 7, and is located on the upper surface of the silicone roller 71. The heating roller lifting motor 7211 drives the heating roller 72 to move down until it is in contact with the silicone roller. The PU film cloth on 71 is in contact; under the drive of the silicone roller drive motor 73, the silicone roller 71 rotates, and at the same time, under the drive of the pressing transmission assembly 74, the heating rol...

Embodiment 2

[0047] This embodiment provides a PU film cloth pressing method based on the above-mentioned PU film cloth pressing equipment, comprising the following steps:

[0048] (1) The PU film cloth covered with PU film is wound on the feeding mechanism 3, and the PU film cloth passes through the guide roller 4 and the flattening roller 5 successively, and the PU film cloth is guided and flattened successively, keeping The PU film cloth moves smoothly;

[0049] (2) Next, the PU film cloth enters between the silicone roller 71 and the heating roller 72 of the pressing mechanism 7, and is located on the upper surface of the silicone roller 71. The heating roller lifting motor 7211 drives the heating roller 72 to move down until it is in contact with the silicone roller. The PU film cloth on 71 is in contact; under the drive of the silicone roller drive motor 73, the silicone roller 71 rotates, and at the same time, under the drive of the pressing transmission assembly 74, the heating rol...

Embodiment 3

[0053] This embodiment provides a PU film cloth pressing method based on the above-mentioned PU film cloth pressing equipment, comprising the following steps:

[0054] (1) The PU film cloth covered with PU film is wound on the feeding mechanism 3, and the PU film cloth passes through the guide roller 4 and the flattening roller 5 successively, and the PU film cloth is guided and flattened successively, keeping The PU film cloth moves smoothly;

[0055] (2) Next, the PU film cloth enters between the silicone roller 71 and the heating roller 72 of the pressing mechanism 7, and is located on the upper surface of the silicone roller 71. The heating roller lifting motor 7211 drives the heating roller 72 to move down until it is in contact with the silicone roller. The PU film cloth on 71 contacts; Under the drive of silica gel roller drive motor 73, silica gel roller 71 rotates, and at the same time under the drive of pressing transmission assembly 74, heating roller 72 follows sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com