Composite fireproof material

A fire-resistant material and fire-resistant technology, applied in the field of fire prevention, can solve the problems of not being able to use multiple fire-proof materials at the same time, and the texture of the fire-proof material is single, and achieve good heat insulation effect, simple structure, and good fire prevention function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

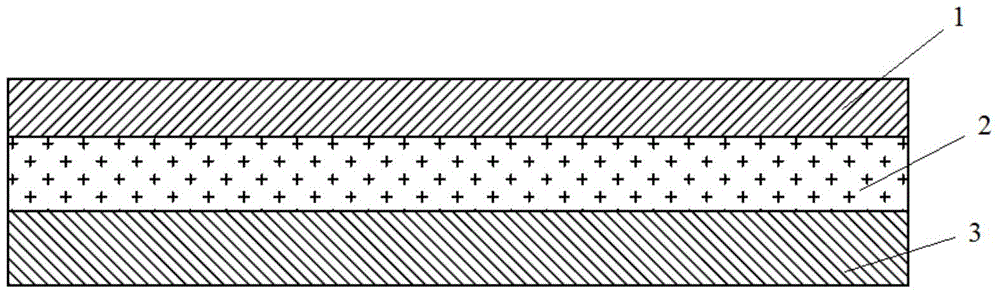

[0011] A composite fireproof material, characterized in that it includes a quartz sand layer 1, a refractory rock wool layer 2, and an aluminum silicate fiber layer 3, wherein the quartz sand layer 1 is located above the refractory rock wool layer 2, and the aluminum silicate fiber layer 3 is located on the Below the refractory rock wool layer 2, the quartz sand layer 1, the refractory rock wool layer 2, and the aluminum silicate fiber layer 3 are closely bonded and compounded into one. Wherein the thickness of the quartz sand layer 1 is 1 cm, the thickness of the refractory rock wool layer 2 is 1.5 cm, and the thickness of the aluminum silicate fiber layer 3 is 2 cm.

[0012] The embodiments of the present invention have been described in detail above, but the content is only a preferred embodiment of the present invention, and is not intended to limit the present invention. All modifications, equivalent replacements and improvements made within the application scope of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com