Method for measuring melting rate of covering slag

A melting rate and mold flux technology, applied in the field of mold flux performance measurement, can solve problems such as poor test reproducibility, errors, and laboratory failure to meet test conditions, improve test repeatability, reduce test costs, Quick and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

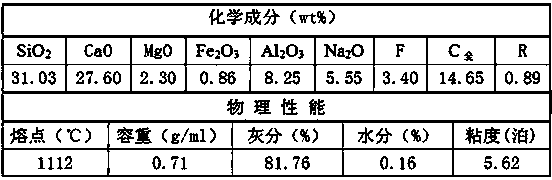

[0026] Take mold flux sample A, its chemical composition and physical properties are as follows:

[0027]

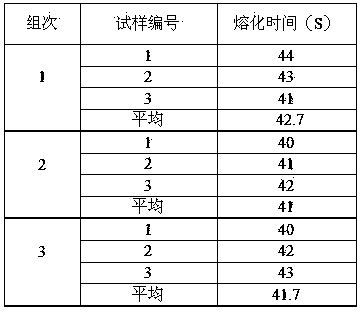

[0028] Divide the mold flux sample into three groups, and use the above-mentioned specific measurement steps to measure the melting speed of the three samples in each group and calculate the average value of each group. The melting speed is shown in the following table:

[0029]

Embodiment 2

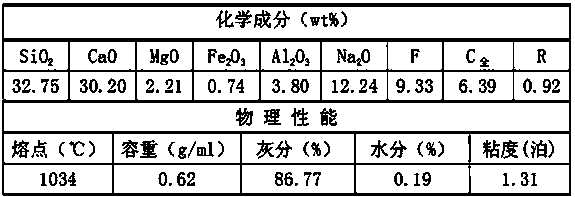

[0031] Take mold flux sample B, its chemical composition and physical properties are as follows:

[0032]

[0033] Divide the mold flux sample into three groups, and use the above-mentioned specific measurement steps to measure the melting speed of the three samples in each group and calculate the average value of each group. The melting speed is shown in the following table:

[0034]

[0035] It can be obtained from the repeated test results of mold slag. This method of testing the melting speed of continuous casting mold slag is simple, has good reproducibility, and has high reliability of test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com