Preparation method of rancidity shaped heat storage material

A thermal storage material and waste technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of thermal storage material volume change, easy leakage, amorphous, etc., to achieve improved compatibility and increased lipophilicity , good miscibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

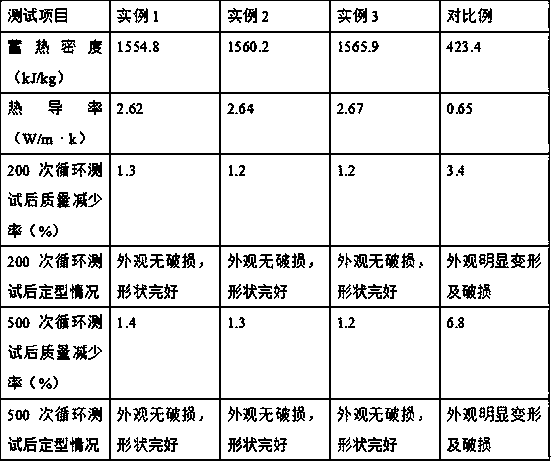

example 1

[0022] Weigh pork suet and place it in a tissue pulverizer for 20 minutes. Mix the pulverized material and water at a mass ratio of 5:1 and put it in an iron pan. Heat to 100°C, keep it warm and cook for 1 hour. After boiling, take advantage of Filter with hot mesh to separate the filtrate; mix the filtrate and carbon nanofibers at a mass ratio of 10:1 and pour it into a stainless steel tray, and move the stainless steel tray into a closed greenhouse with a temperature of 35°C and a relative humidity of 60%. In the middle, let stand rancidity treatment for 5 days to obtain the rancid product for use; add methyl methacrylate to the separatory funnel, wash with 5% sodium hydroxide solution until the washing liquid is colorless, and then deionize Washed with water to neutrality, dried with anhydrous sodium sulfate for 5 days, then distilled under atmospheric pressure, and collected the fraction at 98°C to obtain refined methyl methacrylate; the above-mentioned refined methyl methac...

example 2

[0024] Weigh pork suet and place it in a tissue pulverizer for 25 minutes, mix the pulverized material and water at a mass ratio of 5:1 and put it in an iron pan, heat it to 102°C, keep it warm and cook for 1.5 hours. After boiling, Filter the filtrate with a mesh screen while it is hot, and separate the filtrate; mix the filtrate and carbon nanofibers at a mass ratio of 10:1 and pour it into a stainless steel tray, and move the stainless steel tray into a sealed container with a temperature of 40℃ and a relative humidity of 65%. In the greenhouse, let it stand for 6 days to obtain the rancid product, which is ready for use; add methyl methacrylate to the separatory funnel, wash with 5% sodium hydroxide solution until the washing liquid is colorless, and then use it Ionized water was washed to neutrality, dried with anhydrous sodium sulfate for 6 days, and then distilled at atmospheric pressure. The fraction at 99°C was collected to obtain refined methyl methacrylate; the above-...

example 3

[0026] Weigh pork suet and place it in a tissue pulverizer for 30 minutes. Mix the pulverized material and water at a mass ratio of 5:1 and put it in an iron pan. Heat to 105°C, keep it and cook for 2 hours. Filter with hot mesh to separate the filtrate; mix the filtrate and nano-carbon fiber at a mass ratio of 10:1 and pour it into a stainless steel tray, and move the stainless steel tray into a closed greenhouse with a temperature of 45℃ and a relative humidity of 70%. In the middle, let it stand for 7 days to obtain the rancid product for use; add methyl methacrylate to the separatory funnel, wash with 5% sodium hydroxide solution until the washing liquid is colorless, and then deionize Washed with water to neutrality, dried with anhydrous sodium sulfate for 7 days, then distilled under normal pressure, and collected the fraction at 100°C to obtain refined methyl methacrylate; according to the mass ratio of 500:1, the above refined methyl methacrylate and couple After mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com