Packaging box forming machine

A packaging box and forming machine technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve problems such as waste of resources, increase of production and processing costs, and impact on production capacity, and achieve strong applicability, wide application range, and improved The effect of using flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

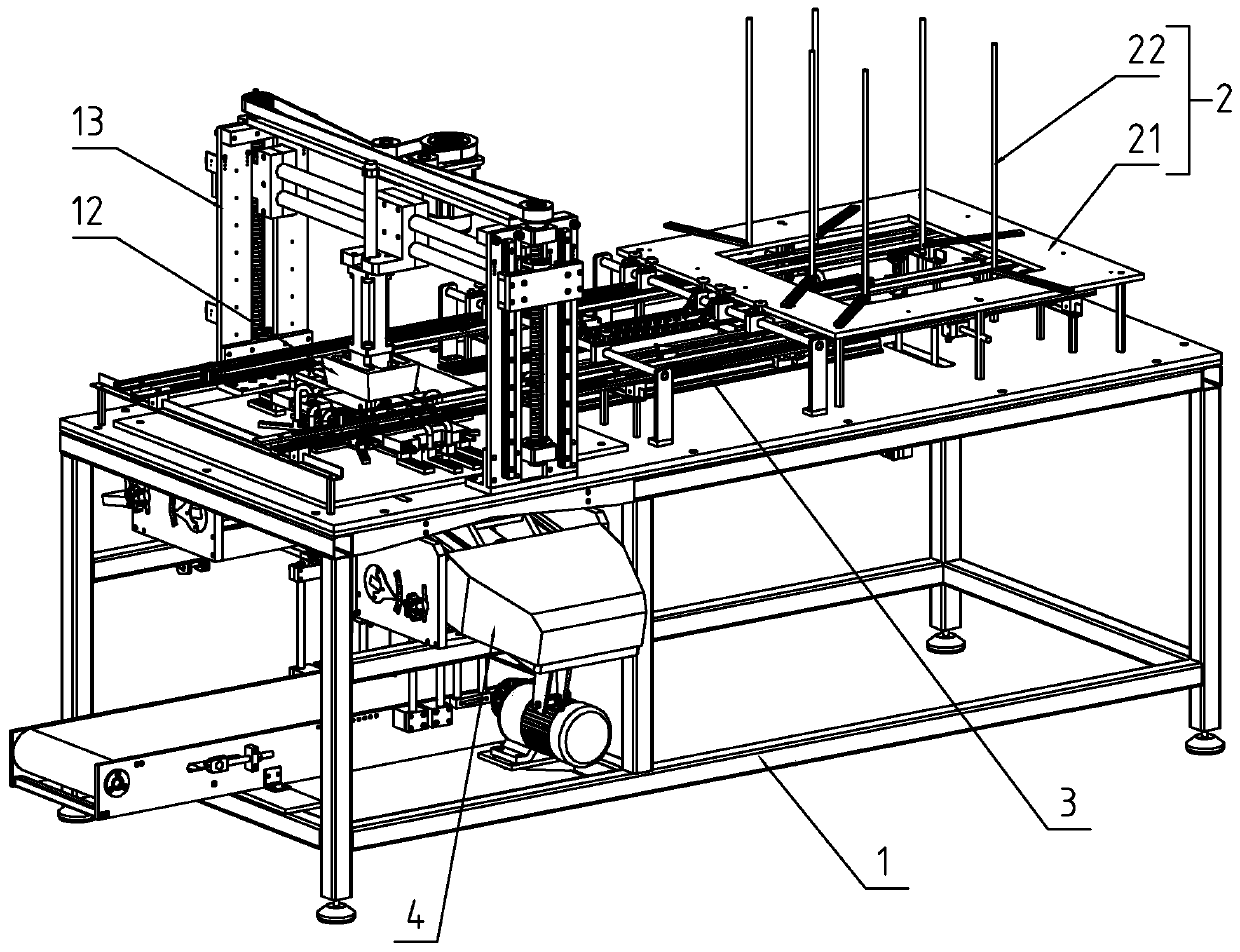

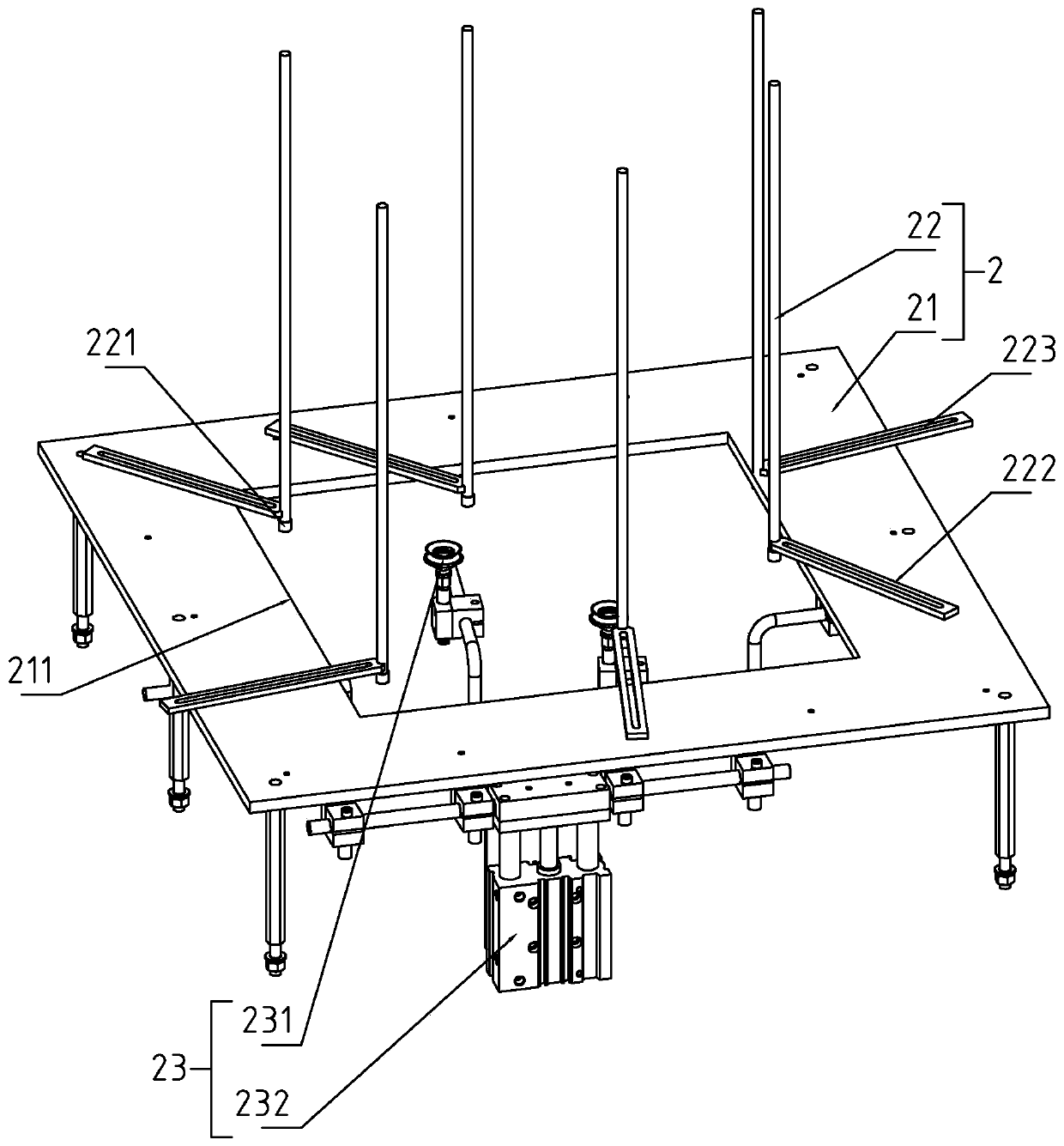

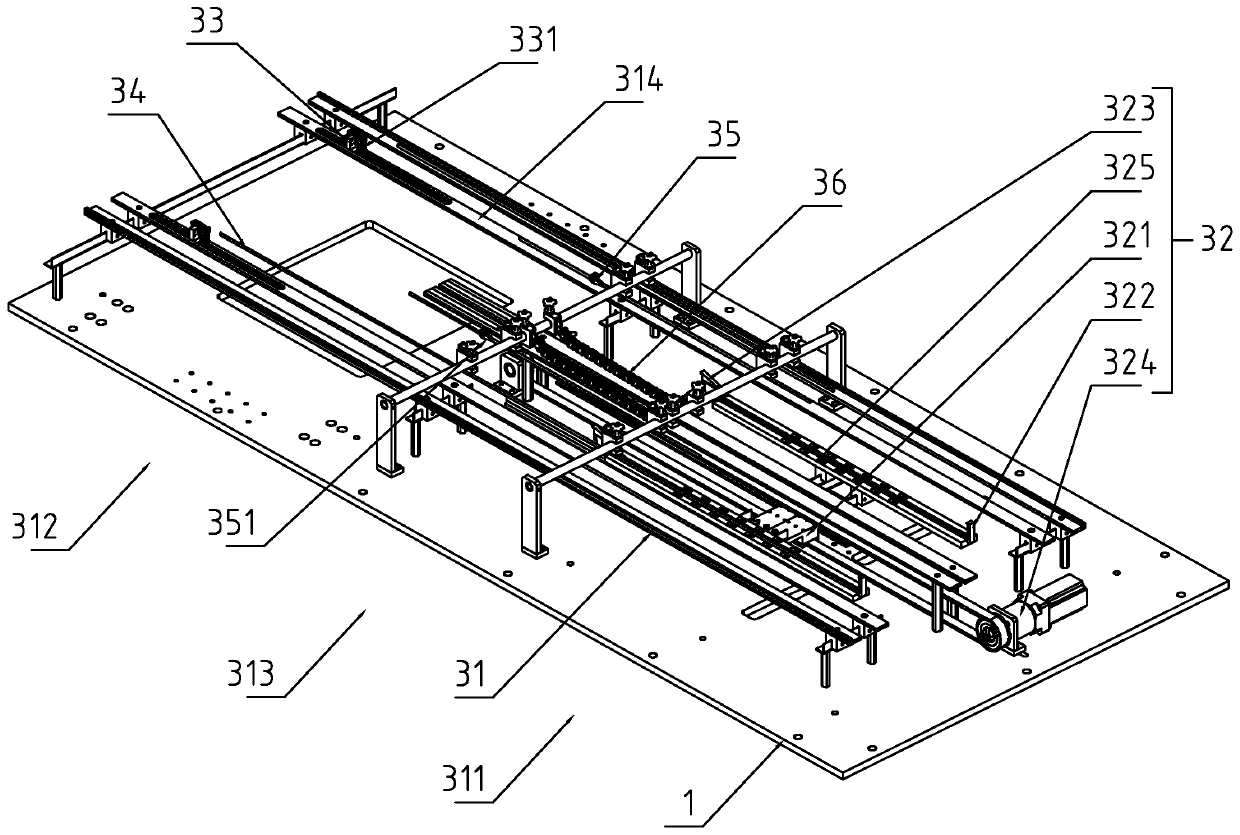

[0029] refer to Figure 1-9 As shown, stacks of creased cardboards are placed on the feed base 21 between each feed bar 22, and the cardboards are restricted from dropping under the action of gravity by the material-limiting structure 221 on each feed bar 22, wherein Each feed rod 22 is distributed on the periphery of the cardboard, and interferes with the periphery of the cardboard to limit the dumping of the cardboard stack, so each feed rod 22 form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com