Pole piece roller compression machine

A pole piece roller and roller press technology is applied in the field of battery pole piece manufacturing equipment, which can solve the problems of inability to achieve pressure balance between upper and lower rolls, easy to generate vibration, low measurement efficiency, etc., to ensure rolling quality and equipment service life, The rolling process is convenient and the effect of reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described in detail through embodiments in combination with the drawings.

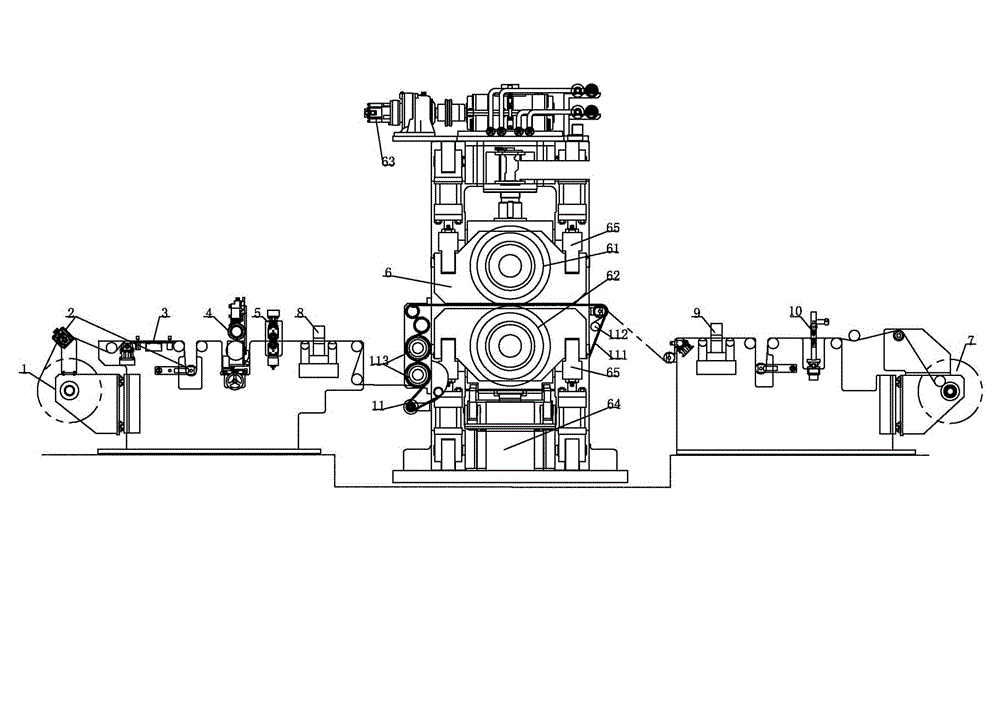

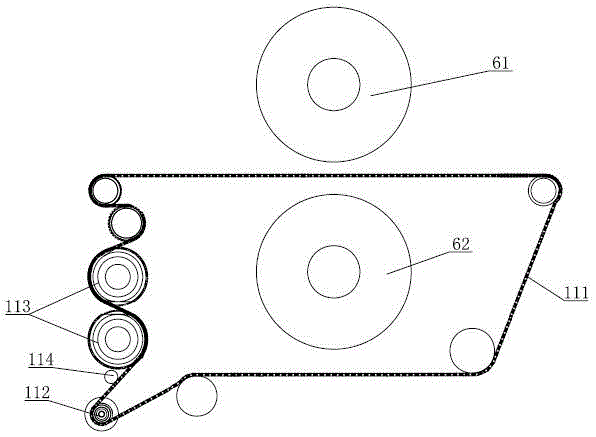

[0031] See figure 1 In one embodiment, the pole piece roller press may include an unwinding mechanism 1, a conveying mechanism, a rolling mechanism 6, and a winding mechanism 7, wherein the rolling mechanism 6 includes a relatively movable upper pressure roller, a lower pressure roller, and a reverse Pressure mechanism and drive mechanism respectively configured for the upper pressure roller and the lower pressure roller. The counter-pressure mechanism may be a hydraulic cylinder or an air cylinder, and is referred to as a counter-pressure cylinder hereinafter. In some preferred embodiments, the pole piece roller press may further include one or more of the tension control mechanism 2, the automatic tape connecting mechanism 3, the trimming mechanism 4, and the powder brushing mechanism 5.

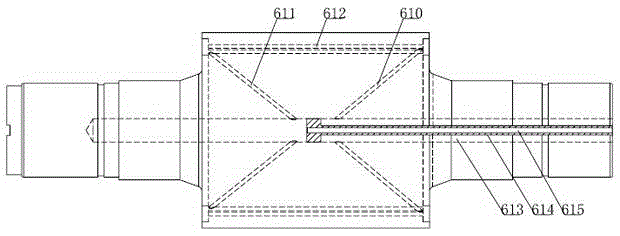

[0032] The driving mechanism of the roller pressing mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com