Film rolling machine and roller surface cleaning device thereof for battery pole pieces

A battery pole piece and cleaning device technology, which is applied to cleaning methods and appliances, cleaning methods using tools, and keeping roll equipment in an effective state, etc. It can avoid problems such as labor consumption, and achieve the effect of avoiding incomplete cleaning, reliable automatic cleaning, and keeping clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

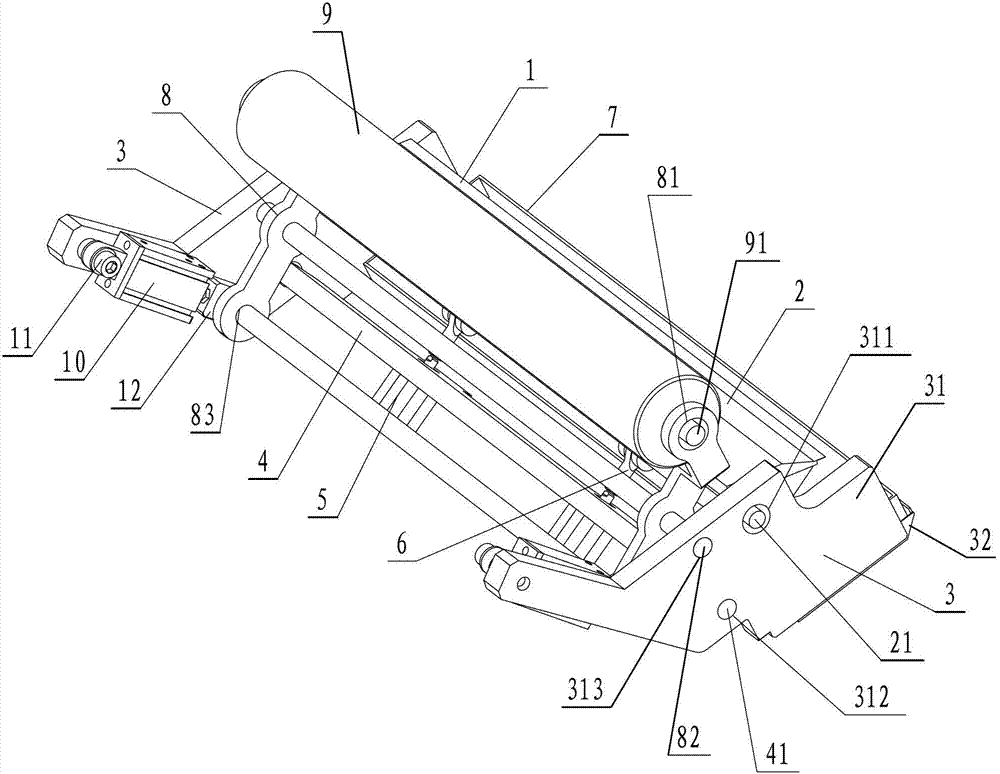

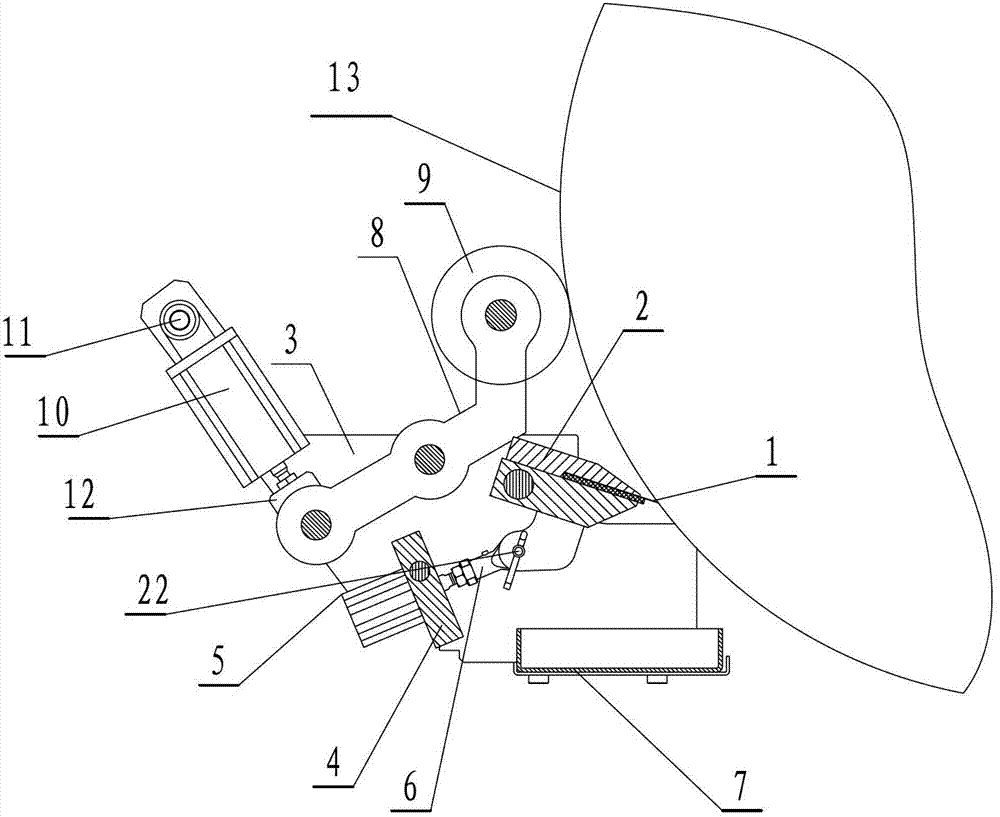

[0020] see figure 1 , 2 , The present embodiment provides a roller surface cleaning device of a battery pole piece film binding machine, which includes a fixed support 3, an adhesive roller mechanism and a scraper mechanism. Wherein the scraper mechanism includes a scraper 1, a scraper turret 2 and a scraper rotating device, and the adhesive roller mechanism includes an adhesive roller 9, an adhesive roller turret 8 and an adhesive roller rotating device. The fixed support 3 is further composed of two parallel side walls 31 and a connecting plate 32 connecting the two side walls 31 .

[0021] The scraper 1 of the above-mentioned scraper mechanism is fixed in the scraper turret 2, and the scraper turret 2 is hinged on the fixed support 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com