Triangular-strip-groove-based annular heating furnace bottom working layer construction method

A ring-shaped heating furnace and strip-shaped groove technology, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of increasing maintenance times, expanding costs, and uneven heating, ensuring rolling quality and extending service life. Longevity and the effect of reducing the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

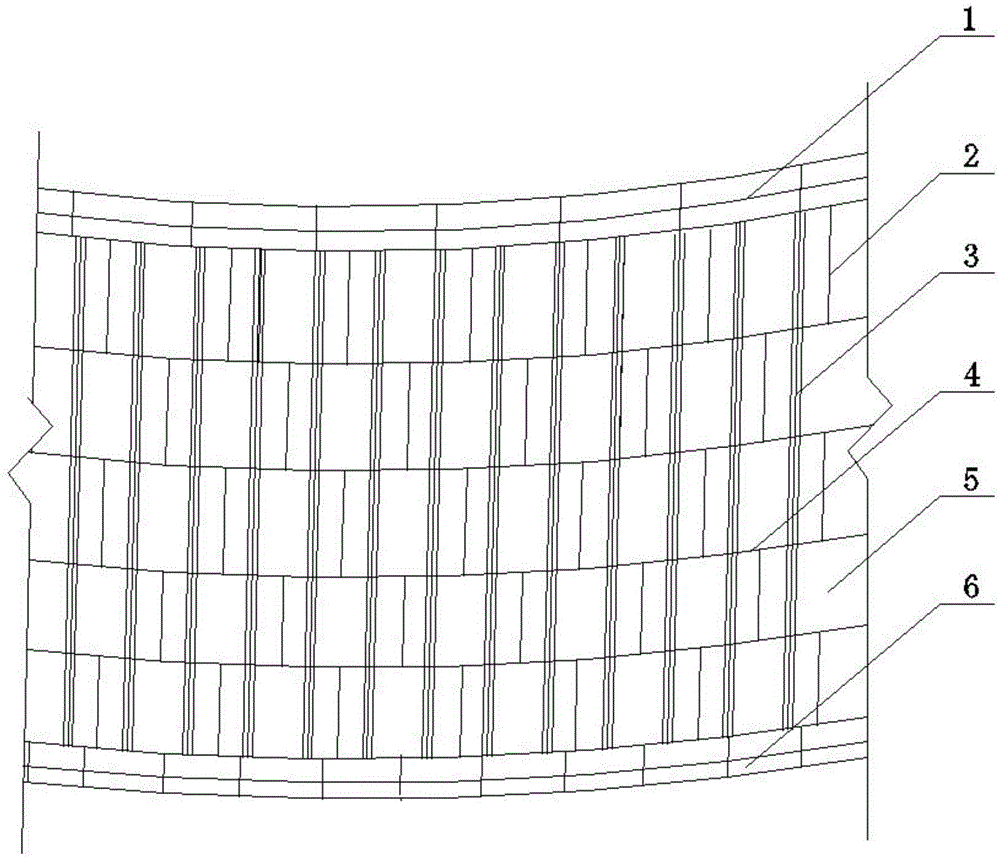

[0019] A construction method for the bottom working layer of an annular heating furnace based on triangular strip grooves, the steps of the construction method are:

[0020] (1) Base line construction: Hang and measure the center line of the incoming and outgoing materials outside the annular heating furnace on the platform outside the furnace. The center line of the incoming and outgoing materials outside the heating furnace is measured on the bottom layer of the annular heating furnace, and used as the reference line of the working layer on the bottom layer of the annular heating furnace;

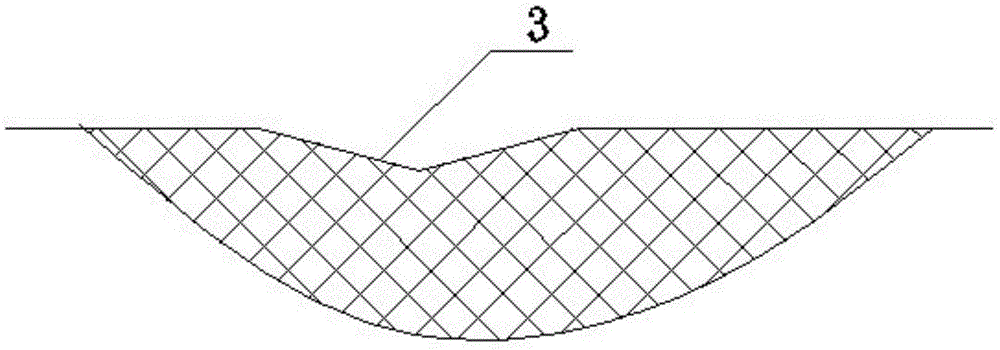

[0021] (2) Support the strip groove mold; install the strip groove mold at radial intervals on the pouring block surface of the working layer between the inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com