Method for measuring phosphor content in cold rolled degreasing agent

A measurement method and degreasing agent technology, applied in the field of cold rolling aids, can solve problems such as degreasing agent interference, achieve good accuracy, strong anti-interference ability, and ensure the effect of rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

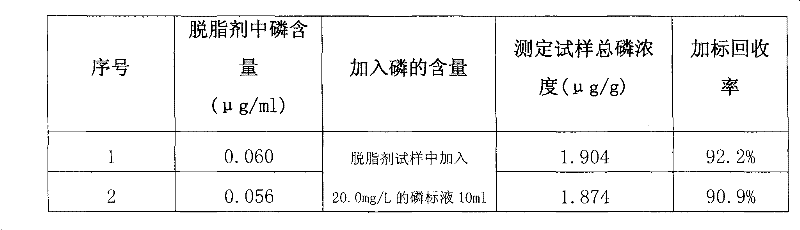

Examples

Embodiment Construction

[0019] A method for measuring phosphorus content in a cold-rolled degreasing agent of the present invention comprises:

[0020] Weigh 2.0000g of the sample degreasing agent in a polytetrafluoroethylene beaker, add a small amount of pure water, and add dilute nitric acid to adjust to pH=4-9;

[0021] Then add 2-5 ml of the dilute nitric acid, and digest on the electric furnace;

[0022] After boiling, slowly add 2-8 ml of hydrogen peroxide and keep it at a slight boil for 10 minutes;

[0023] Transfer the digestion solution to the test solution in a volumetric flask, control 0.5-2% nitric acid medium, dilute it with water to the mark, and shake well to obtain the sample to be tested;

[0024] The sample to be tested is injected into the ICP quartz tube, and the light radiation intensity generated by the ground state atoms of phosphorus at the detection wavelength of 213.618 nm is measured by plasma spectroscopy, thereby quantifying the content of phosphorus in the degreaser sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com