Uniform cleaning device suitable for cleaning structure of precision machine tool equipment

A precision machine tool and cleaning device technology, applied in metal processing equipment, lighting and heating equipment, cleaning methods using liquids, etc., can solve the problems of low water pressure, low air pressure, insufficient decontamination ability, poor cleaning effect, etc., to achieve increased Great rinsing blow force, good rinsing effect and drying effect, and even cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

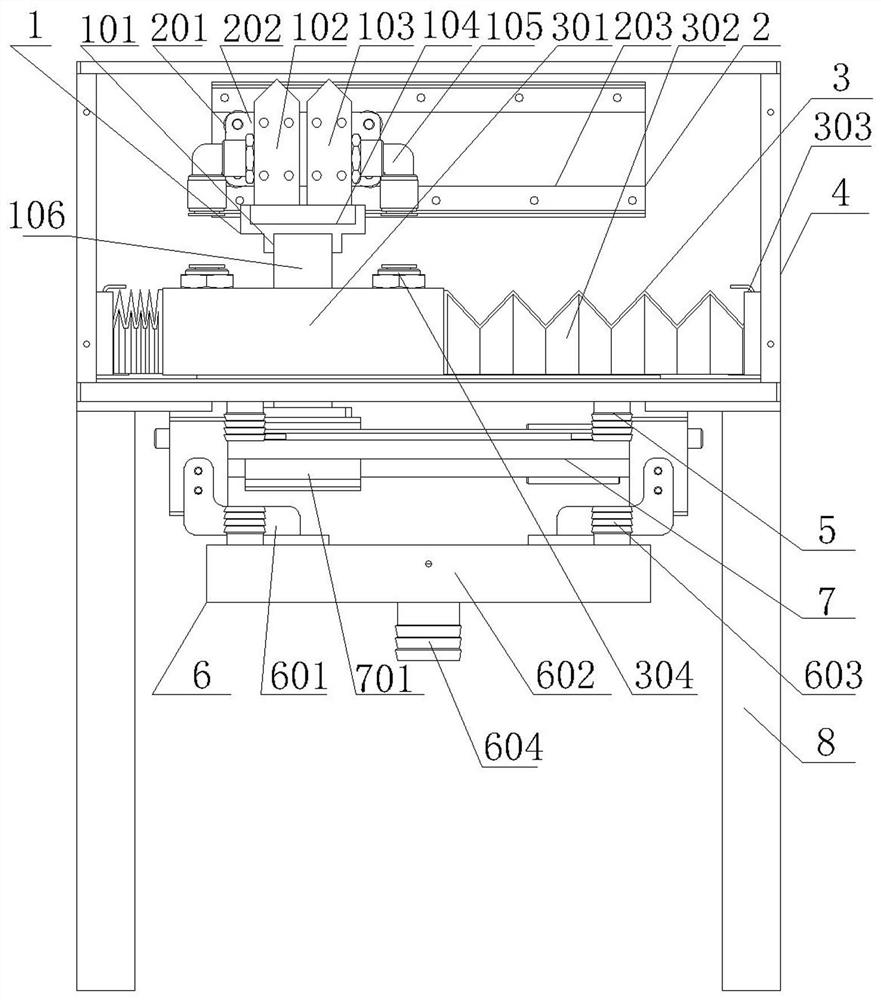

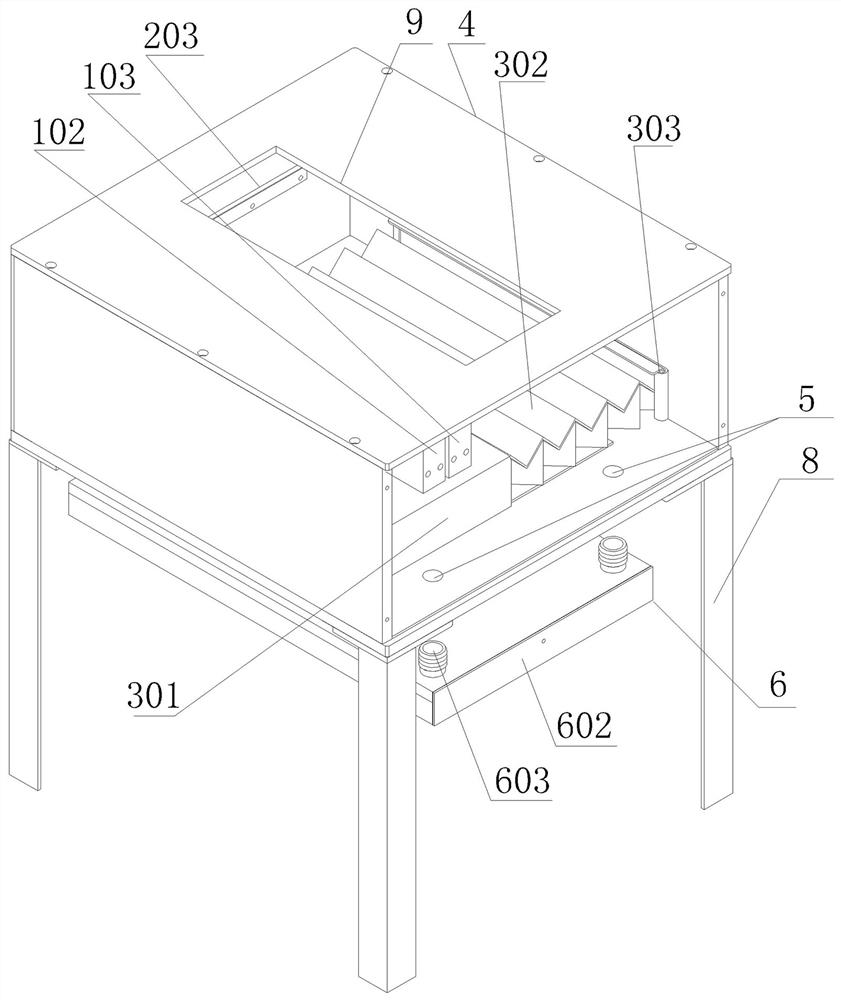

[0027] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

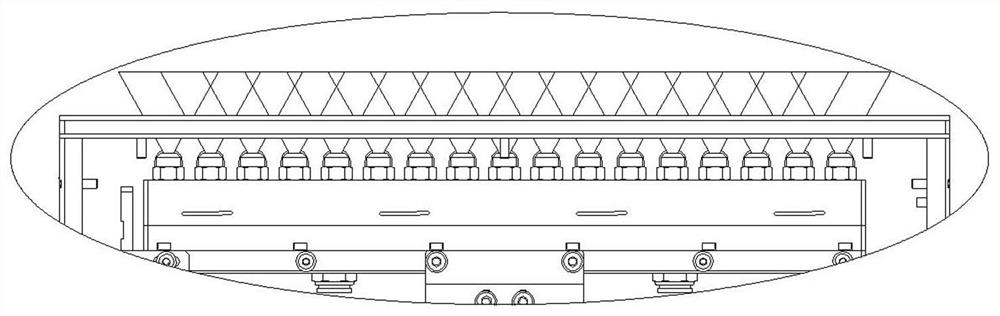

[0028] like figure 1 Shown is a schematic diagram of the upper part of the traditional continuous row nozzle structure cleaning module, which adopts a structural design in which more water spray heads and air jet heads are arranged and distributed in a cross manner to achieve a longer distance cleaning effect; this traditional continuous row nozzles The water spray head and air jet head of the structural cleaning module are fan-shaped structures, and the water sprayed is also fan-shaped. The advantage is that the coverage area is large. The cleaning effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com