Dirt-removing, washing and processing device for steel wire rope

A processing device and a technology for steel wire ropes, which are applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc. Avoid scrap and facilitate walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

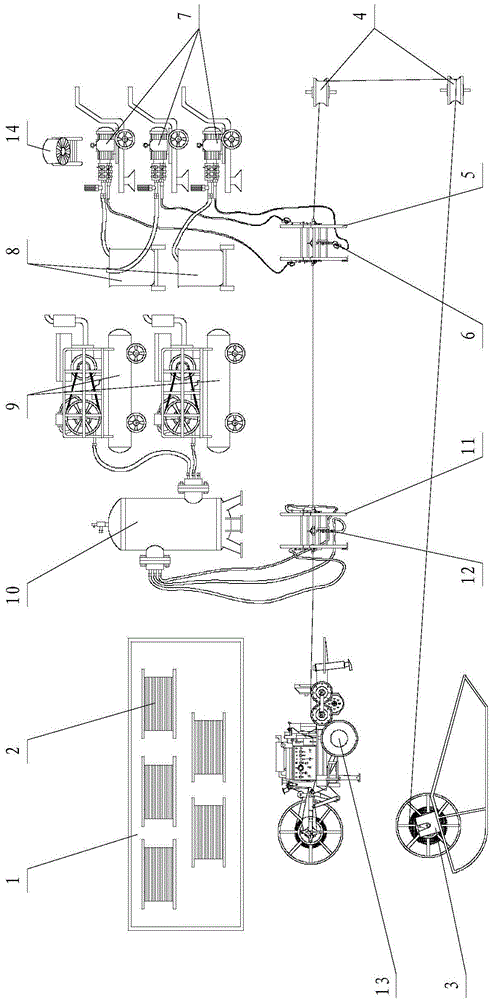

[0024] Such as figure 1 Shown, the present invention comprises ship type frame 3, steering tackle 4, cleaning mechanism, drying mechanism and tractor 13, to be cleaned, the reel 2 that is wrapped with wire rope is soaked in immersion pool 1; The reel 2 wrapped with steel wire rope soaked in 1 is rotated and installed on the boat frame 3, and the steel wire rope on the drum 2 wrapped with steel wire rope without cleaning is released from the boat frame 3, and after being turned by two steering blocks 4, In turn, it enters the cleaning mechanism for cleaning and the drying mechanism for drying. After cleaning and drying, the steel wire rope is wound up by the tractor.

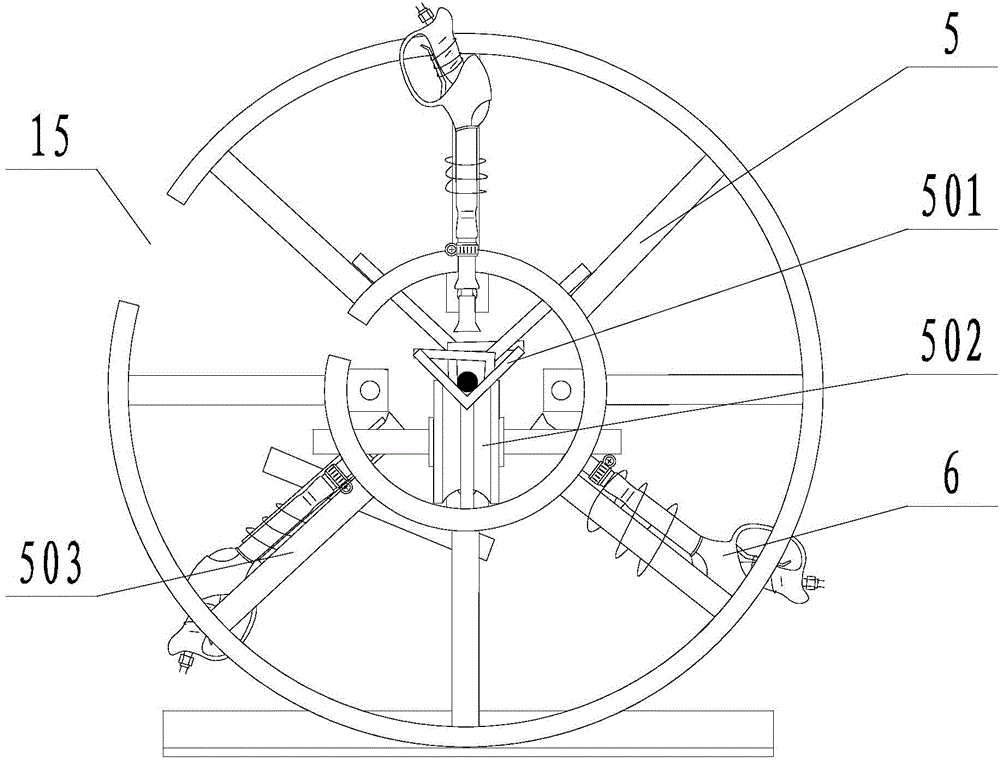

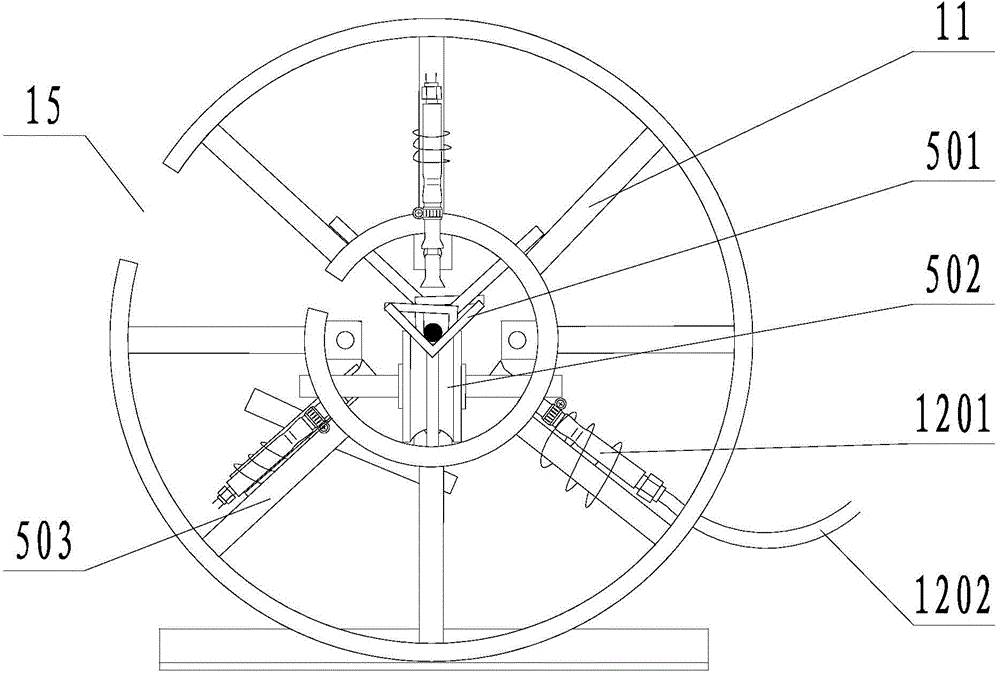

[0025] The cleaning mechanism comprises a water pump 7, a bucket 8, a water gun bracket 5, a fan 14 and a plurality of water guns 6 evenly distributed on the water gun bracket 5, the water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com