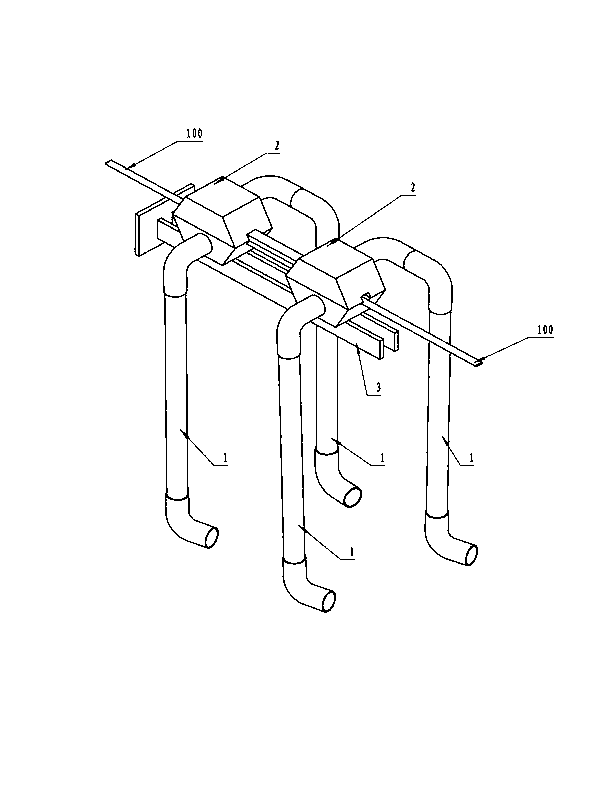

Electromagnetic wire drying device

A technology of electromagnetic wire and center position, which is used in the manufacture of circuits, electrical components, cables/conductors, etc. It can solve the problems of unreasonable structure, too large air outlet diameter, and inability to achieve drying effect, and achieve reasonable structure and good drying effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

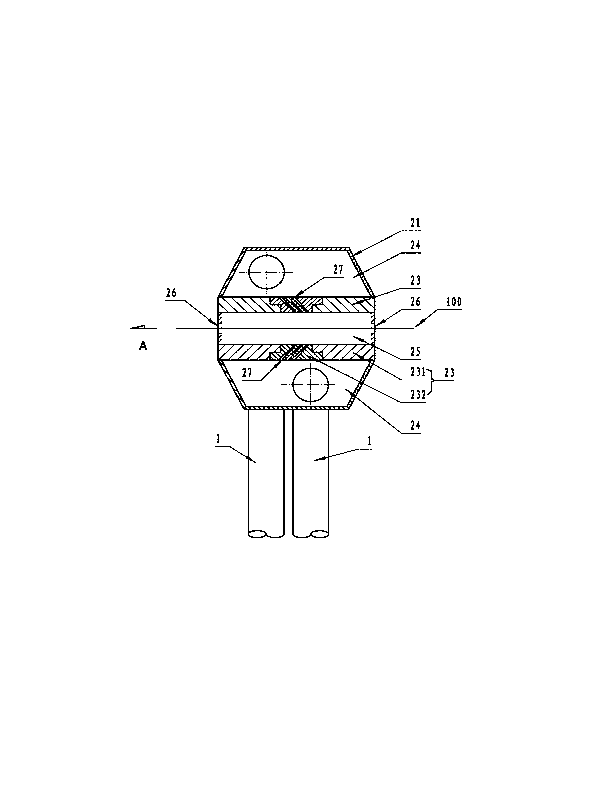

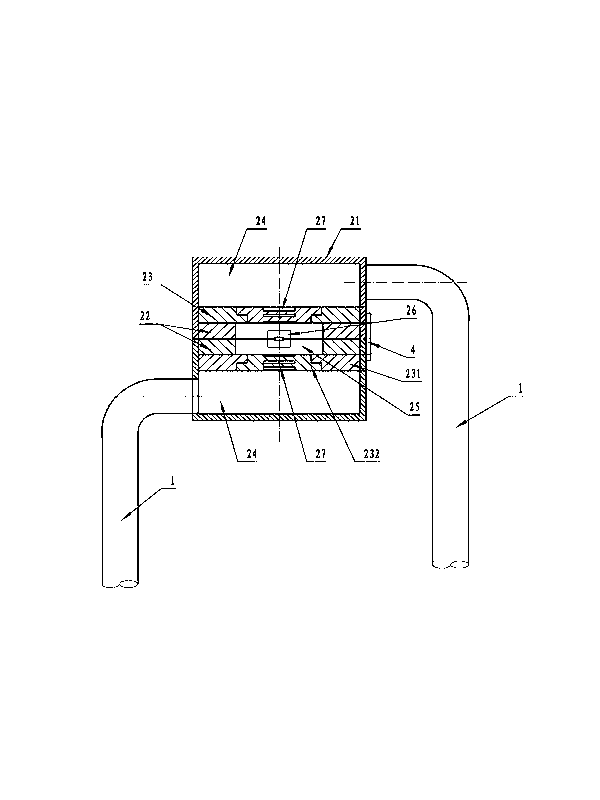

[0027] Embodiment two, see Figure 7 , the figure shows another blowing mechanism 2 of the electromagnetic wire drying device of the present invention. The difference from the blowing mechanism 2 in the previous embodiment is that the housing 21 is cylindrical and integral. The baffle 23 arranged in the housing 21 is in the shape of a cylindrical sleeve, the rear end of the baffle 23 has a locking ring 233 with a diameter larger than the front end and threaded surface, and the rear end of the housing 21 has a diameter smaller than the middle The threaded inner hole 211 whose position is matched with the locking ring 233 of the partition 23, the partition 23 is screwed with the threaded inner hole 211 at the rear end of the housing 21 through the locking ring 233 at the rear end, and the outer end of the locking sleeve 231 Lock nut 5 is arranged on and is used for locking both, prevents from loosening. The partition 23 divides the housing 21 into an outer air inlet chamber 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com