A drying oven for fast drying auto parts

A technology for auto parts and drying boxes, which is used in drying, drying machines, drying solid materials, etc., can solve problems such as unsatisfactory drying speed, long time, and unfavorable production efficiency, so as to facilitate switching and improve drying. Dry speed, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

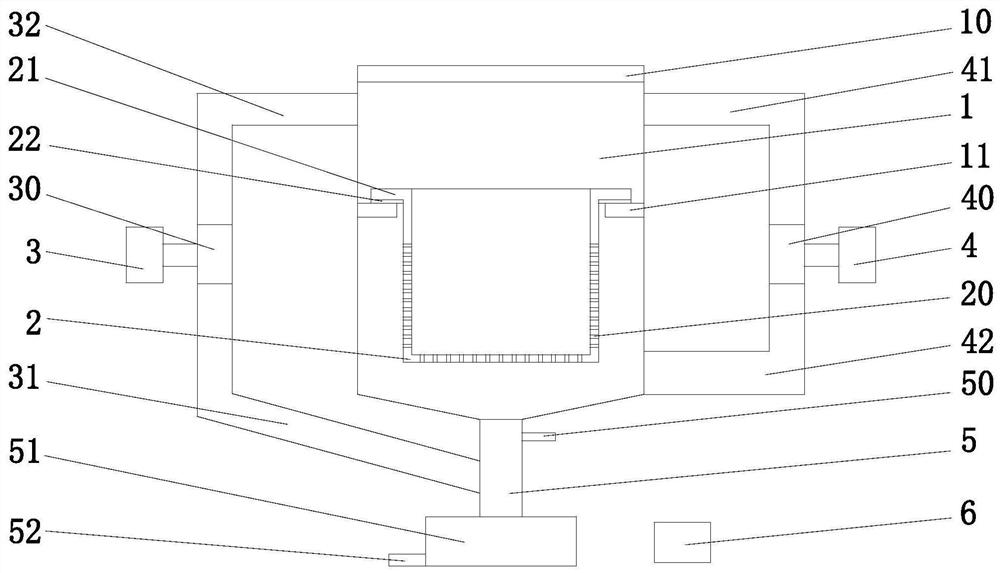

[0016]Seefigure 1 , The present invention is a drying box for auto parts with fast drying, including a box body 1, a baffle ring 11, a container 2, a first hot air pipe 41, a second hot air pipe 42, and a first suction pipe 31 , The second suction pipe 32, the through hole 20, the liquid outlet pipe 5, the electric control valve 50, the liquid contact box 51, the control device 6, the upper end of the box body 1 is open, and the upper end of the box body 1 is covered with a sealing cover 10 , A ring of retaining ring 11 is provided on the inner wall of the box body 1, a container 2 with an open upper end is provided in the box body 1, and a ring of flange 21 is provided on the outer wall of the top end of the container body 1, and the flange 21 is supported on the retaining ring On 11, the bottom wall and side wall of the container 2 are provided with a number of through holes 20, the bottom of the box body 1 is provided with a liquid outlet tube 5, and the end of the liquid outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com