Efficient heat dissipation electric power cabinet for electric power engineering

A technology of power engineering and power cabinets, applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve problems such as heating of electrical components, limited number of fans, affecting normal operation of electrical components, etc., to achieve reduction The amount of dust and the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

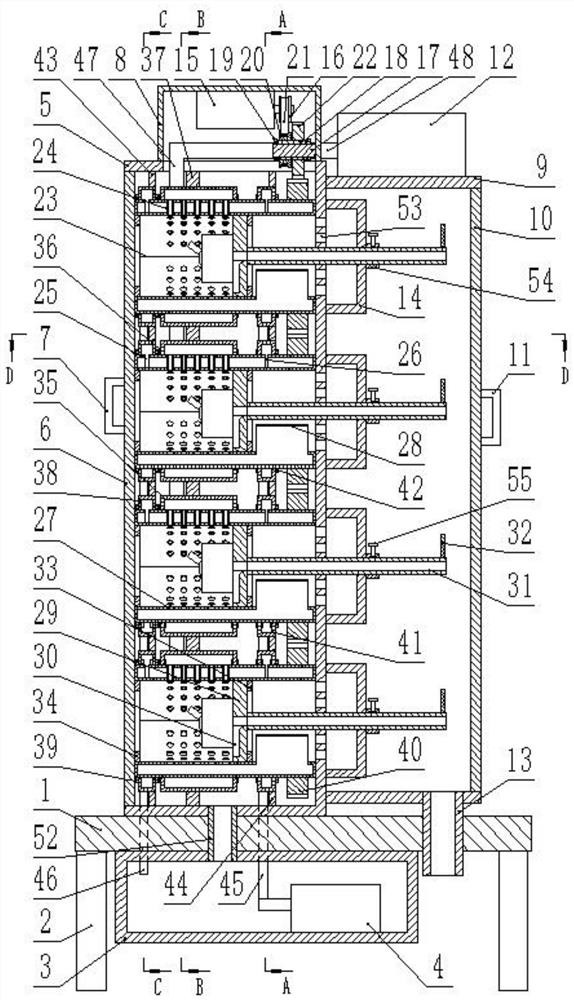

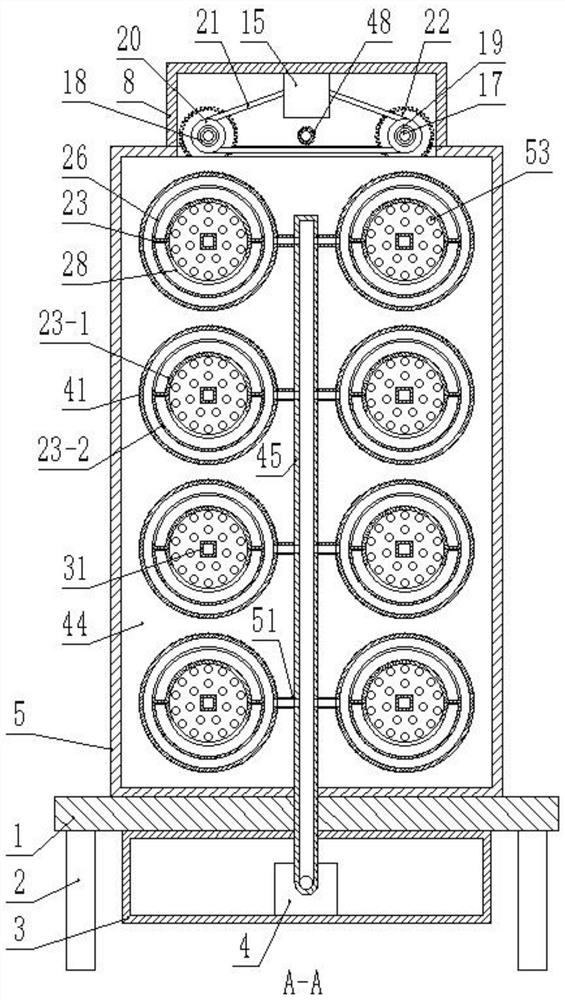

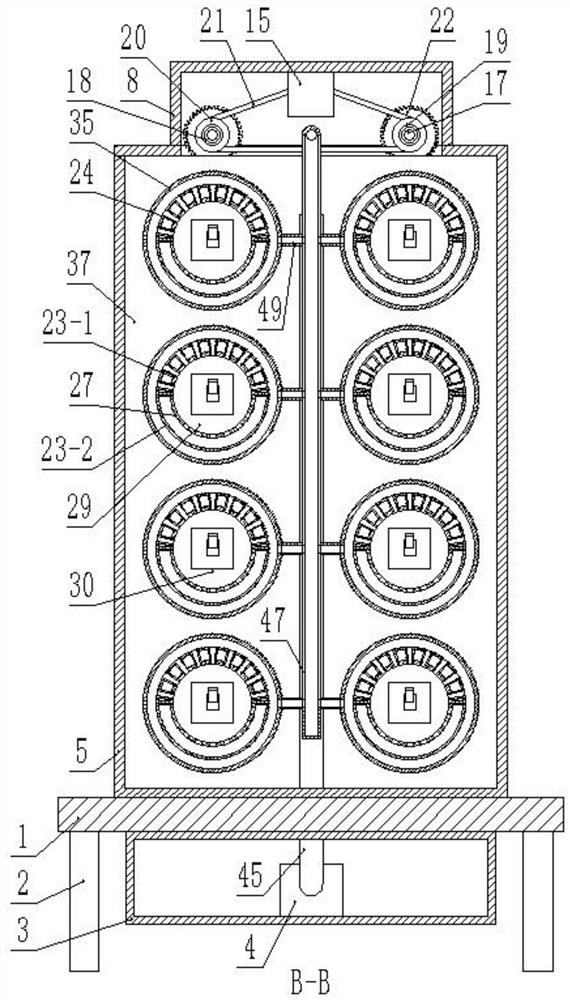

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a high-efficiency heat dissipation power cabinet for electric power engineering, including a base 1, is characterized in that; the four corners of the bottom of the base 1 are respectively fixed with outriggers 2, and the bottom of the base 1 is fixed with a water tank 3, and the water tank 3 is a A water inlet is opened on the side, a submersible pump 4 is fixedly installed on one side of the inner bottom of the water tank 3, a power cabinet body 5 is fixedly installed on the top surface of the base 1, and a box door 6 is hinged on one side of the power cabinet body 5, so A handle 7 is fixed on the side wall of the box door 6, a box body 9 is fixed on the other side of the power cabinet body 5, and a first box door 10 is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com