Intelligent multi-functional printing and dyeing device for non-woven fabric for processing paper diapers

A technology for non-woven fabrics and diapers, which is applied in the field of printing and dyeing devices of non-woven fabrics for multi-functional diaper processing, can solve the problems of inconvenient collection of dyes, easy movement, environmental pollution, etc., so as to improve work efficiency, meet printing and dyeing needs, and avoid Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

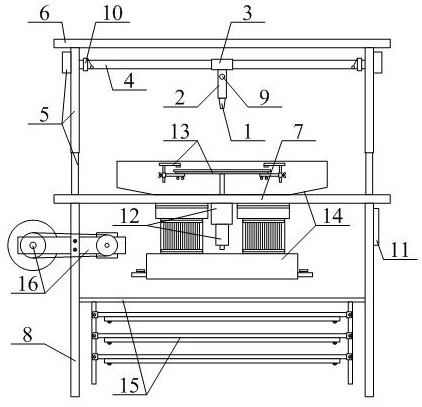

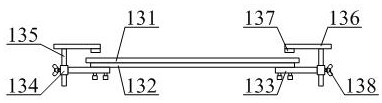

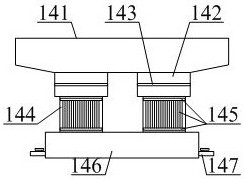

[0034] Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, the printing and dyeing device of the non-woven fabric of intelligent multifunctional paper diaper processing, comprises printing and dyeing nozzle 1, printing and dyeing nozzle 2, automatic slider 3 , linear slide rail 4, electric moving rod 5, frame 6, machine base 7, support leg 8, dye connector 9, limit switch 10, intelligent control panel 11, deceleration rotating motor 12, non-woven fabric printing and dyeing to prevent movement Pressing plate structure 13, printing and dyeing dye residue collection filter box structure 14, adjustable drying plate structure 15 after printing and dyeing, and rotating storage wheel structure 16 after printing and dyeing drying. The printing and dyeing nozzle 1 is threadedly connected to the printing and dyeing nozzle 2; the longitudinal upper end of the printing and dyeing nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com