Clamping and fixing device for processing treatment of complex-form materials

A material processing, clamping and fixing technology, applied in the field of machining, can solve problems such as poor stability, low machining accuracy, and unfavorable use, and achieve the effects of improving stability, improving machining accuracy, and facilitating positioning and machining work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

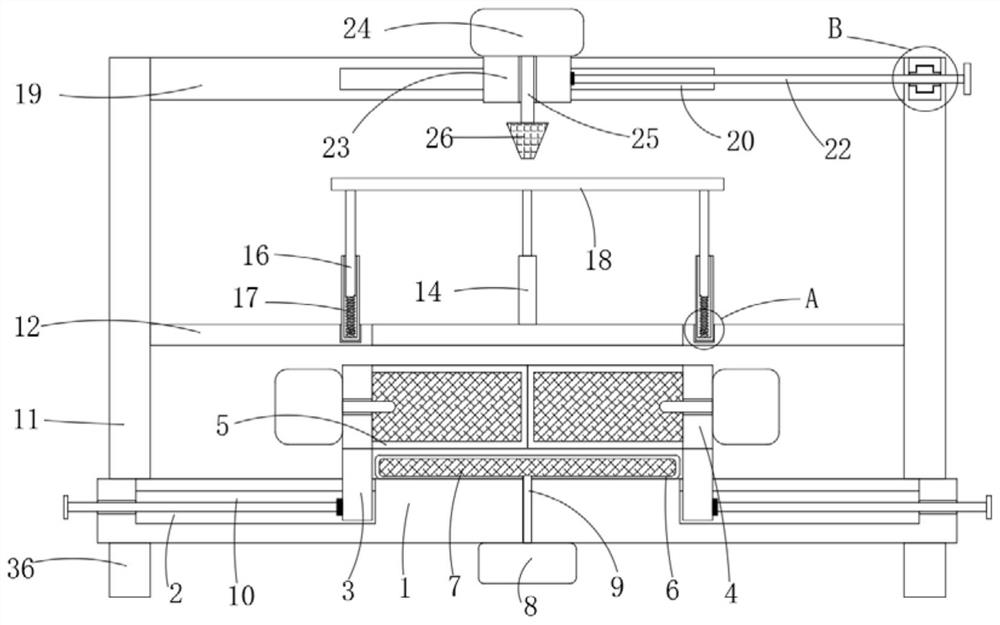

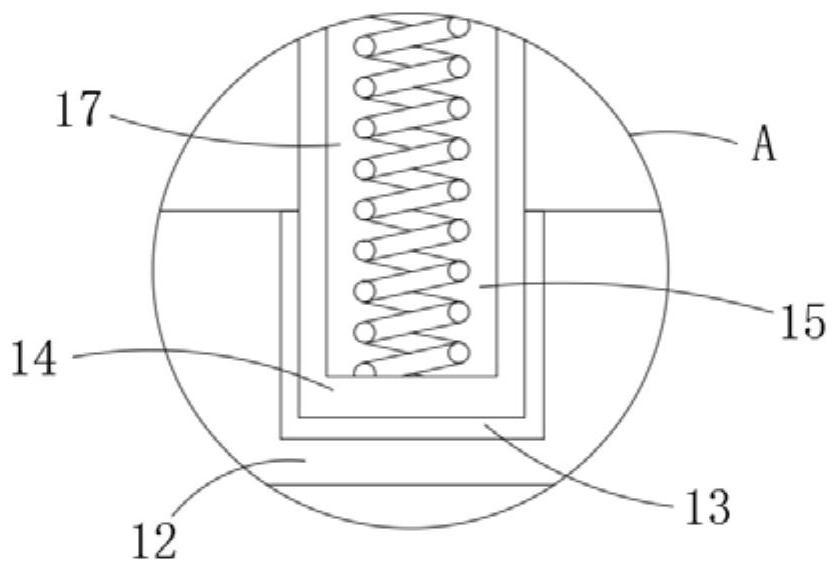

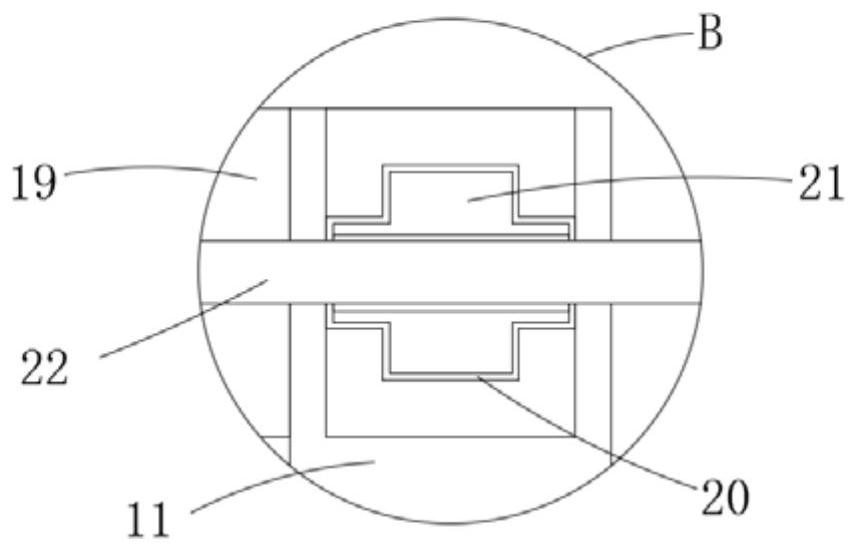

[0023] refer to Figure 1-4 , a clamping and fixing device for complex shape material processing, including a base 1, four feet 36 arranged symmetrically to each other are fixedly connected to the lower end surface of the base 1, and the feet 36 can complete the supporting work for the base 1 more stably , and then complete the supporting work of the whole device, and the feet 36 can keep the base 1 away from the supporting surface, so that the power supply equipment 8 under the base 1 can safely complete the power supply work, and the upper end surface of the base 1 is provided with two Symmetrically arranged sliding grooves 2, sliding blocks 3 are slidably connected in the two sliding grooves 2, and clamping plates 4 are fixedly connected on the side walls of the two sliding blocks 3 away from the sliding groove 2, and the two clamping plates 4 The side walls close to each other are fixedly connected with elastic bags 5, and the upper end surface of the base 1 is fixedly con...

Embodiment 2

[0028] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 lies in the setting of the two positioning devices. The support ring 12 is provided with two positioning devices arranged in a staggered manner. The staggered arrangement allows the two positioning devices to cooperate to complete the center positioning of the material, which is extremely It greatly facilitates the user to accurately process regular and symmetrical materials. The two positioning devices all include two round rods 27 that are slidably connected in the annular groove 13. The heights of the round rods 27 in the two positioning devices are different, so that Effectively avoid the two positioning devices from interfering with each other during work. The sliding connection of the round rod 27 in the annular groove 13 facilitates the user to move the round rod 27, and then the positioning device can complete the positioning work at a suitable position, which is also convenient for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com