Novel noodle production process

A production process and noodle technology, used in food ingredients as thickeners, food science, applications, etc., can solve problems such as inability to achieve, reduce production efficiency, and increase production costs, and achieve the effect of avoiding breakage and enhancing toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

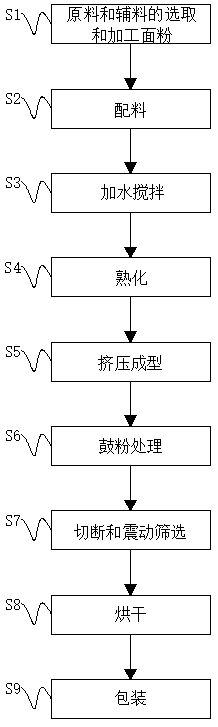

Method used

Image

Examples

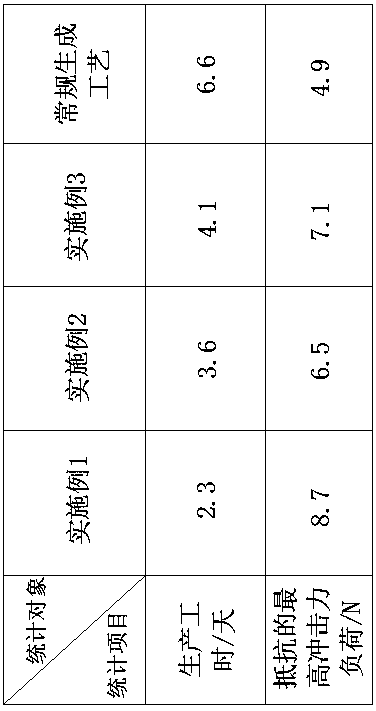

Embodiment 1

[0035] S1. Selection and processing of raw materials and auxiliary materials Flour: first select high-quality wheat, salt, thickener, oxidant, emulsifier, gluten and purified water without pests and impurities, and then process the selected high-quality wheat in sequence Cleaning, crushing, grinding and sifting processes to finally make refined flour, the thickener is a combination of sodium carboxymethylcellulose, gull gum, konjac powder and modified starch, and the oxidizing agent is azodicarbonamide and vitamin C Composition, emulsifier is the composition of monoglyceride, sucrose ester and sodium stearoyl lactylate;

[0036] S2. Ingredients: 70 parts of refined flour raw materials prepared in step S1, 7 parts of salt, 3 parts of thickener, 3 parts of oxidizing agent, 3 parts of emulsifier and 2 parts of emulsifier selected in step S1 were weighed respectively through the weighing mechanism in the batching equipment. After the weighing of each component is completed, pour it ...

Embodiment 2

[0045] S1. Selection and processing of raw materials and auxiliary materials Flour: first select high-quality wheat, salt, thickener, oxidant, emulsifier, gluten and purified water without pests and impurities, and then process the selected high-quality wheat in sequence Washing, crushing, grinding and sifting processes to finally make refined flour, the thickener is a combination of sodium carboxymethylcellulose and modified starch, the oxidizing agent is azodicarbonamide, and the emulsifier is monoglyceride and sodium stearoyl lactylate Compositions;

[0046] S2. Ingredients: 60 parts of refined flour raw materials prepared in step S1, 5 parts of salt, 1 part of thickener, 1 part of oxidant, 1 part of emulsifier and 1 part of emulsifier selected in step S1 were weighed respectively through the weighing mechanism in the batching equipment. After the weighing of each component is completed, pour it into the mixing and mixing equipment for mixing and dough;

[0047] S3. Add wa...

Embodiment 3

[0055] S1. Selection and processing of raw materials and auxiliary materials Flour: first select high-quality wheat, salt, thickener, oxidant, emulsifier, gluten and purified water without pests and impurities, and then process the selected high-quality wheat in sequence Cleaning, crushing, grinding and screening processes, finally made into refined flour, the thickener is sodium carboxymethyl cellulose, the oxidant is vitamin C, and the emulsifier is monoglyceride;

[0056] S2, batching: weigh 80 parts of refined flour raw materials prepared in step S1, and 10 parts of salt, 5 parts of thickener, 5 parts of oxidizing agent, 5 parts of emulsifier and 3 parts of selected in step S1 respectively through the weighing mechanism in the batching equipment After the weighing of each component is completed, pour it into the mixing and mixing equipment for mixing and dough;

[0057] S3. Add water and stir: put the pure water selected in step S1 into the heating equipment for preheating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com