Automatic machining equipment for mass production of threaded rods

An automatic processing and threaded rod technology, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low processing efficiency, unfavorable mass production, burns, etc., and achieve the effects of improving processing efficiency, saving manpower, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

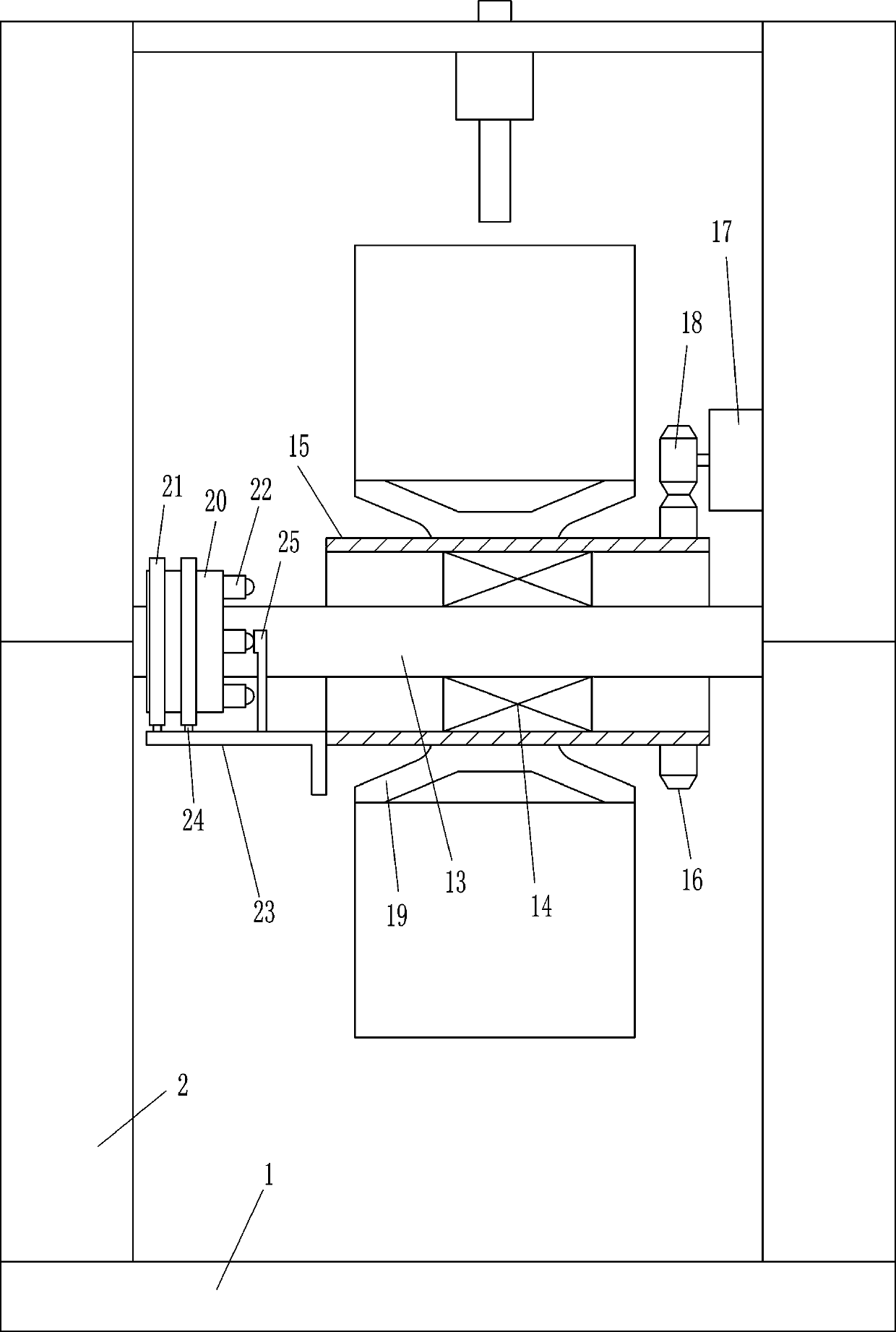

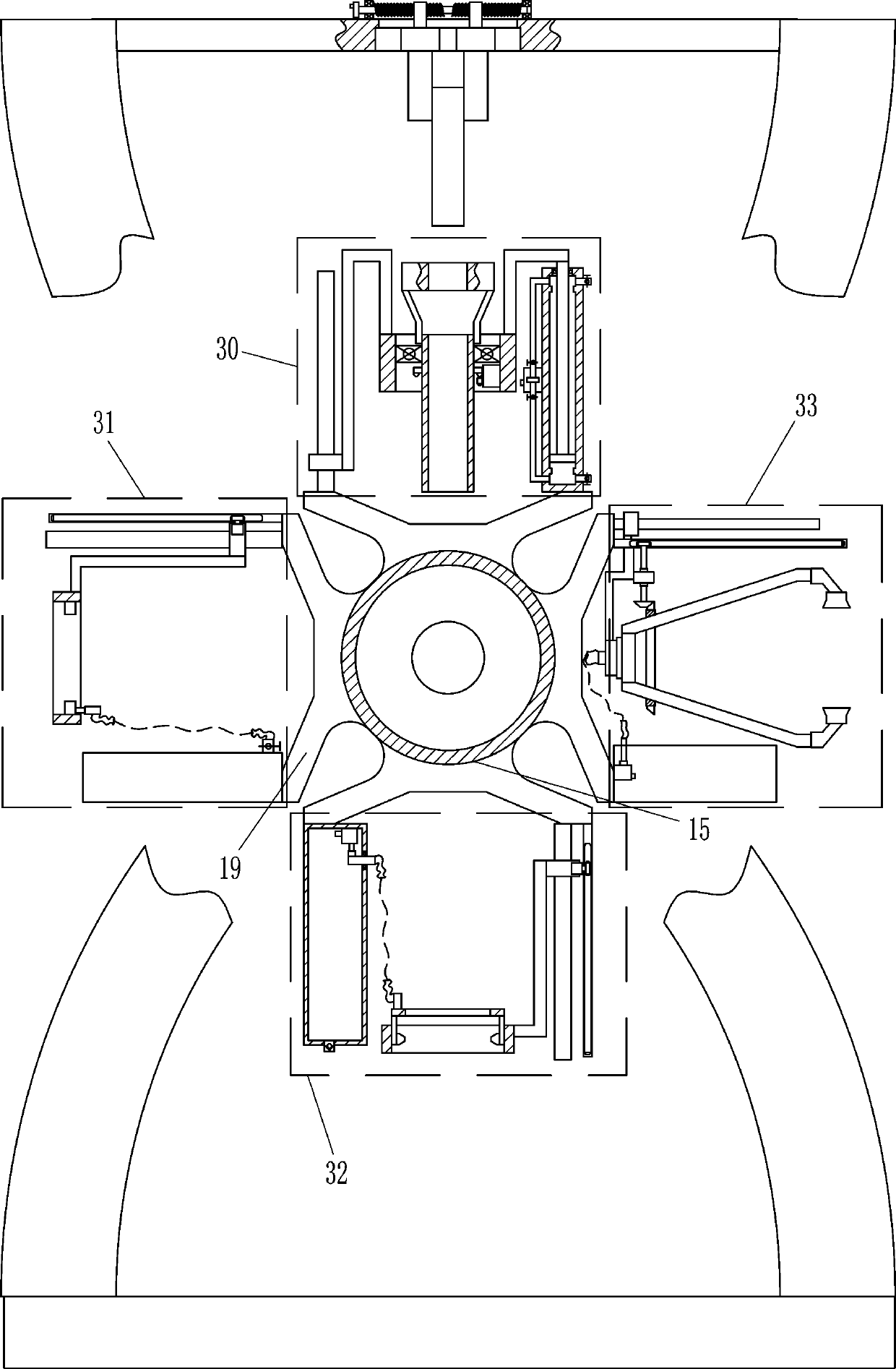

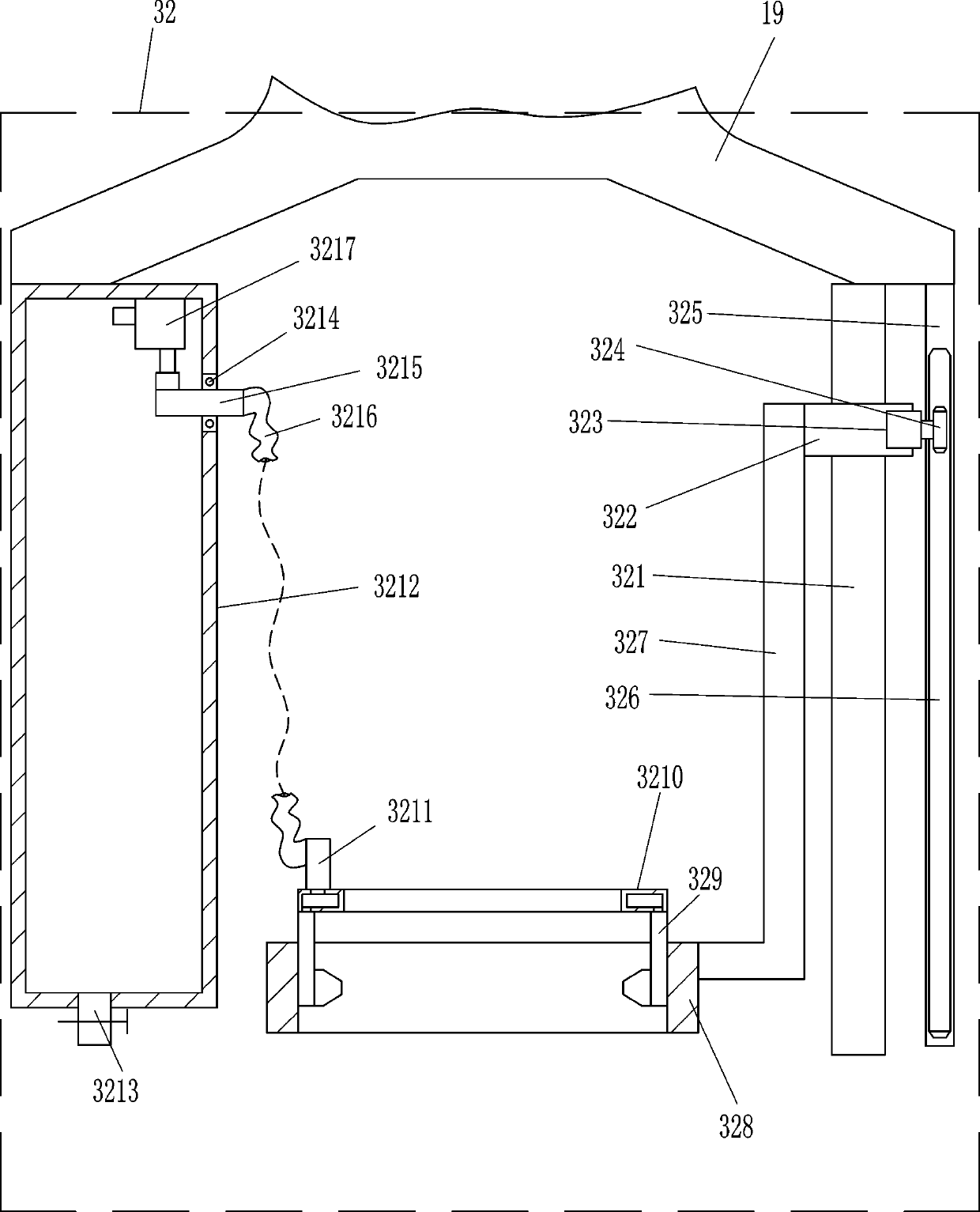

[0023] A mass-produced threaded rod automatic processing equipment, such as Figure 1-10 As shown, it includes a bottom plate 1, a control box 101, a main power switch 102, a mounting frame 2, a mounting plate 3, a slide rail 4, a slider 5, a clamp 6, a nut 8, a first bearing seat 9, and a first rotating rod 10 , Screw rod 11, handle 12, fixed rod 13, second bearing seat 14, first rotating ring 15, first gear 16, drive motor 17, second gear 18, fixed frame 19, rotating disc 20, brush 21 , contact switch 22, the first L-shaped bar 23, electrode 24, contact head 25, tapping device 30, thermal processing device 31, quenching device 32 and anti-rust treatment device 33, a control box 101 is installed in the middle of the top of the bottom plate 1, The bottom plate 1 is connected to the control box 101 by means of bolt connection. The control box 101 includes a power supply module and a control module. The main power switch 102 is connected to the top of the bottom plate 1, and th...

Embodiment 2

[0027] A mass-produced threaded rod automatic processing equipment, such as Figure 1-10As shown, it includes a bottom plate 1, a control box 101, a main power switch 102, a mounting frame 2, a mounting plate 3, a slide rail 4, a slider 5, a clamp 6, a nut 8, a first bearing seat 9, and a first rotating rod 10 , Screw rod 11, handle 12, fixed rod 13, second bearing seat 14, first rotating ring 15, first gear 16, drive motor 17, second gear 18, fixed frame 19, rotating disc 20, brush 21 , contact switch 22, the first L-shaped bar 23, electrode 24, contact head 25, tapping device 30, thermal processing device 31, quenching device 32 and anti-rust treatment device 33, a control box 101 is installed in the middle of the top of the bottom plate 1, The control box 101 includes a power supply module and a control module, the power supply module and the switching power supply are connected by a line, the control module and the power supply module are connected by a line, the front rig...

Embodiment 3

[0032] A mass-produced threaded rod automatic processing equipment, such as Figure 1-10 As shown, it includes a bottom plate 1, a control box 101, a main power switch 102, a mounting frame 2, a mounting plate 3, a slide rail 4, a slider 5, a clamp 6, a nut 8, a first bearing seat 9, and a first rotating rod 10 , Screw rod 11, handle 12, fixed rod 13, second bearing seat 14, first rotating ring 15, first gear 16, drive motor 17, second gear 18, fixed frame 19, rotating disc 20, brush 21 , contact switch 22, the first L-shaped bar 23, electrode 24, contact head 25, tapping device 30, thermal processing device 31, quenching device 32 and anti-rust treatment device 33, a control box 101 is installed in the middle of the top of the bottom plate 1, The control box 101 includes a power supply module and a control module, the power supply module and the switching power supply are connected by a line, the control module and the power supply module are connected by a line, the front ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com