Patents

Literature

51results about How to "To achieve anti-rust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-rust spraying fluid for metals

ActiveCN104294274AShort film forming timeImprove quick-drying performanceSodium molybdateIsobutyl alcohol

The invention provides anti-rust spraying fluid for metals, which is composed of the following components in parts by mass: 12-15 parts of triethanolamine, 4-5 parts of borax, 1-2 parts of sodium molybdate, 3-5 parts of sodium bisulfate, 1-2 parts of diethanolamine, 2-3 parts of isobutanol, 0.5-1 parts of isopropyl alcohol, 0.5-1 parts of sodium chloride, 8-12 parts of ethanol, and 85-95 parts of water. When the anti-rust spraying fluid for metals disclosed by the invention is splayed on a metal workpiece, an anti-oxidation protection film can be formed on the surface of the metal workpiece, and the film is compact in tissue structure and fine in particles, so that a rust protection effect is achieved; the anti-rust spraying fluid for metals disclosed by the invention is short in film-forming time and good in fast drying property, and can form a film in 2-3 minutes; and in a normal environment, metals can be prevented from rusting in 5-6 months.

Owner:武汉腾耀新材料工程有限公司

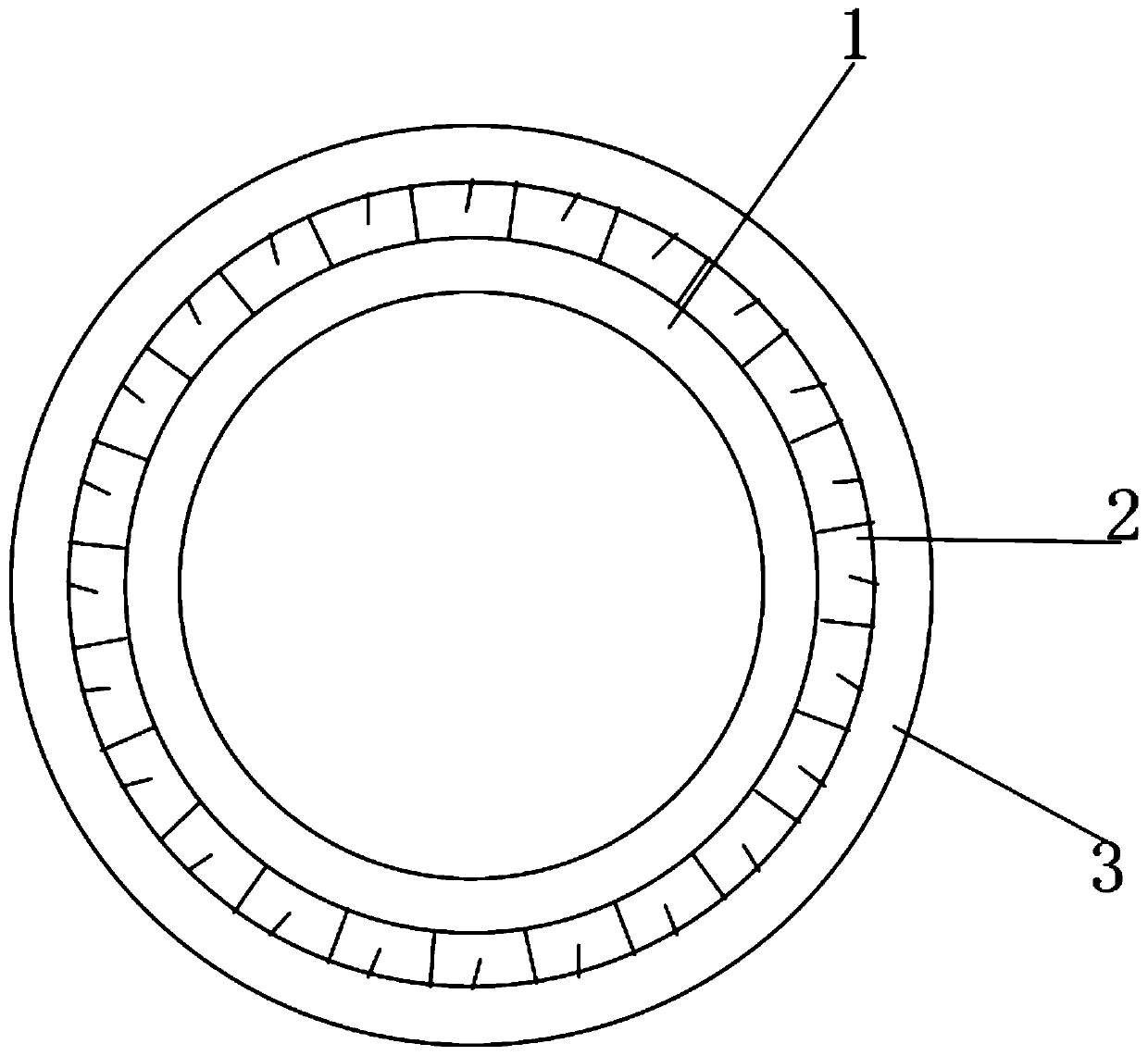

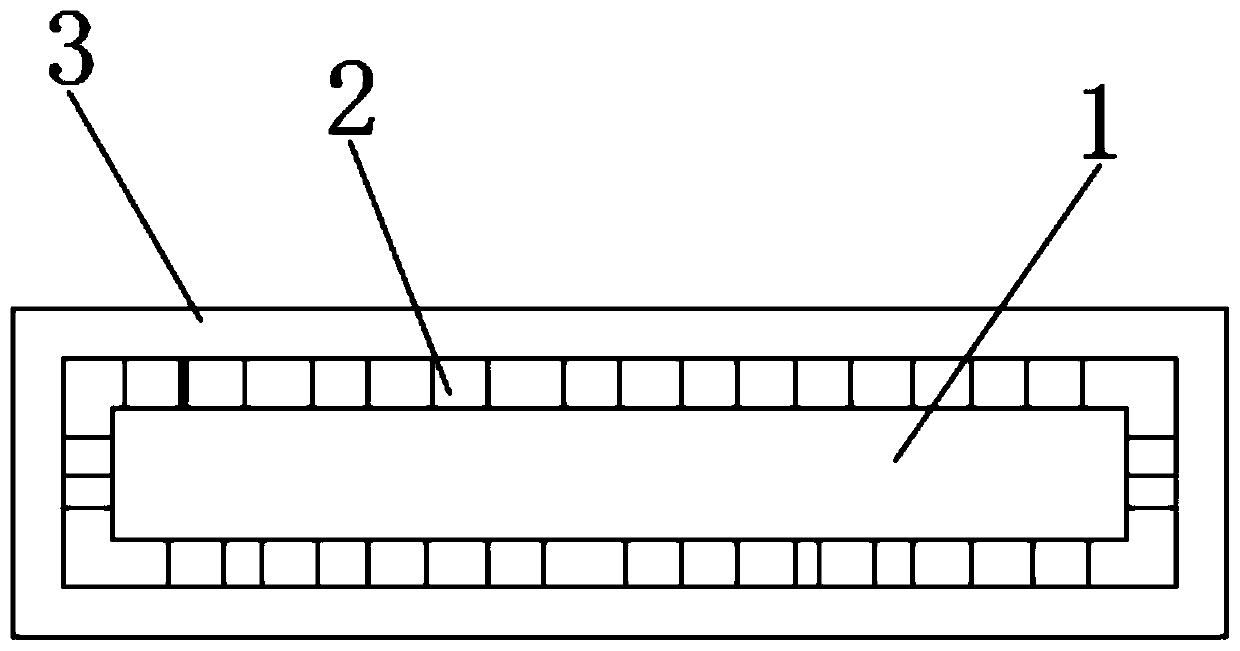

High-strength oxidation-resisting anti-rust film

InactiveCN102173151AIncrease productivityReduce manufacturing costFlexible coversWrappersVolatile corrosion inhibitorAlcohol

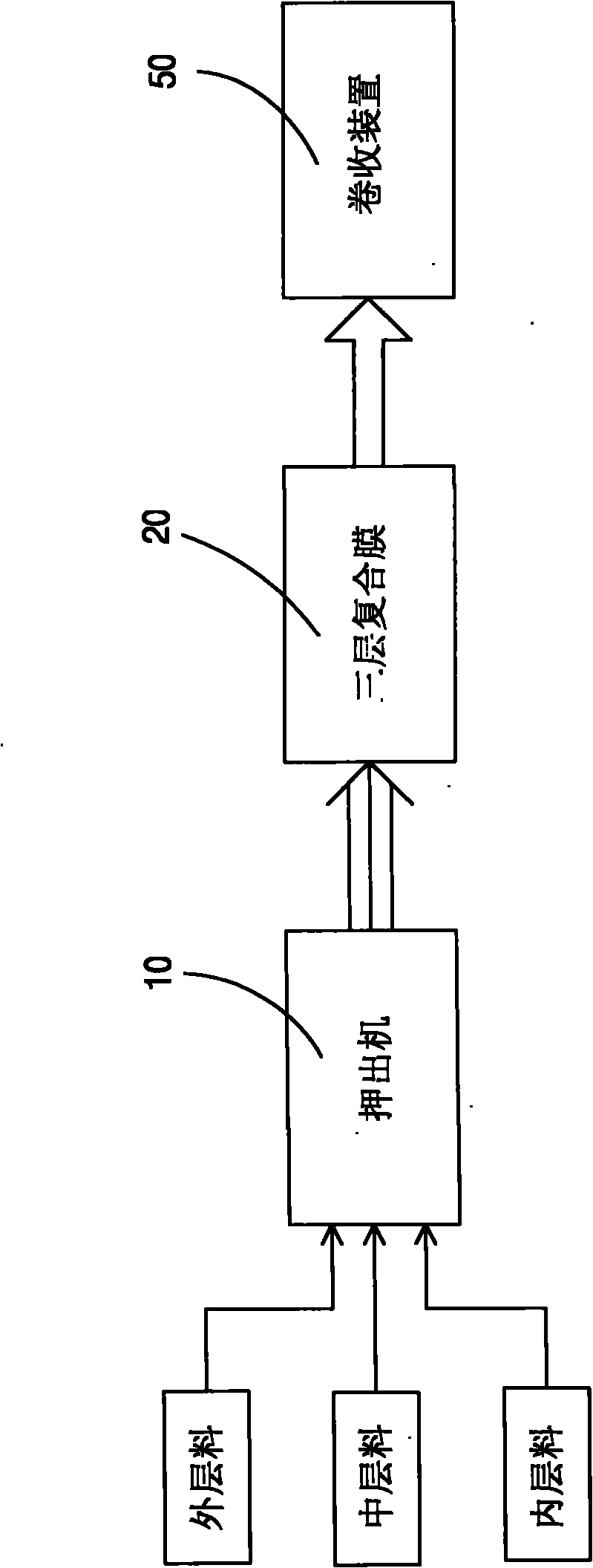

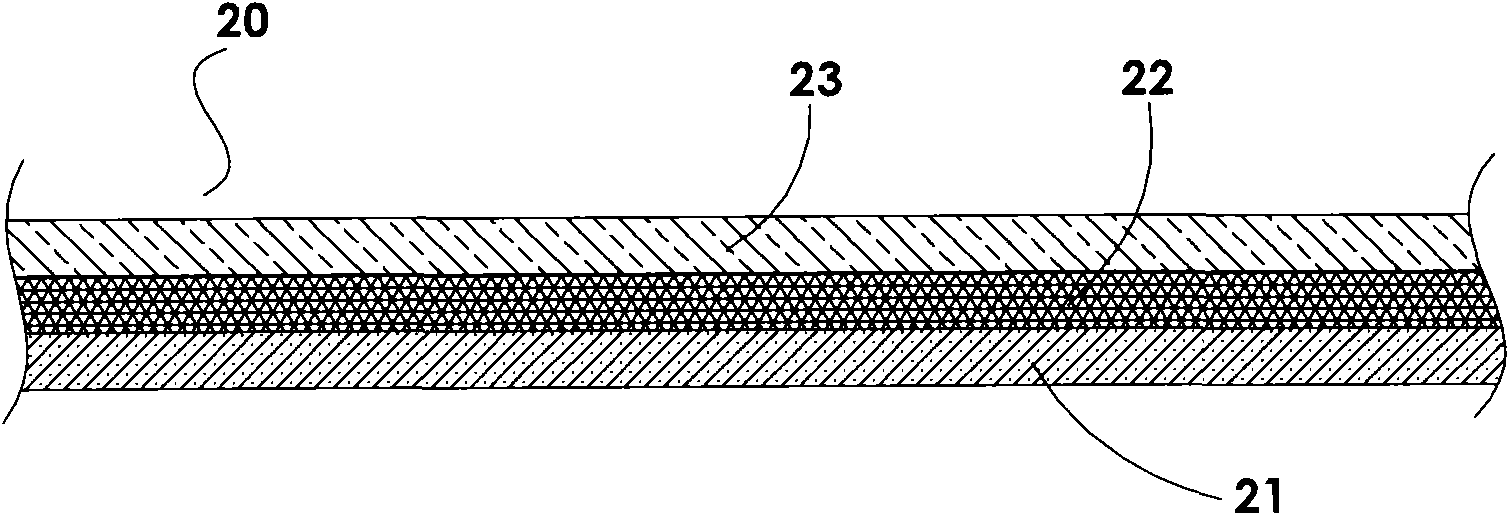

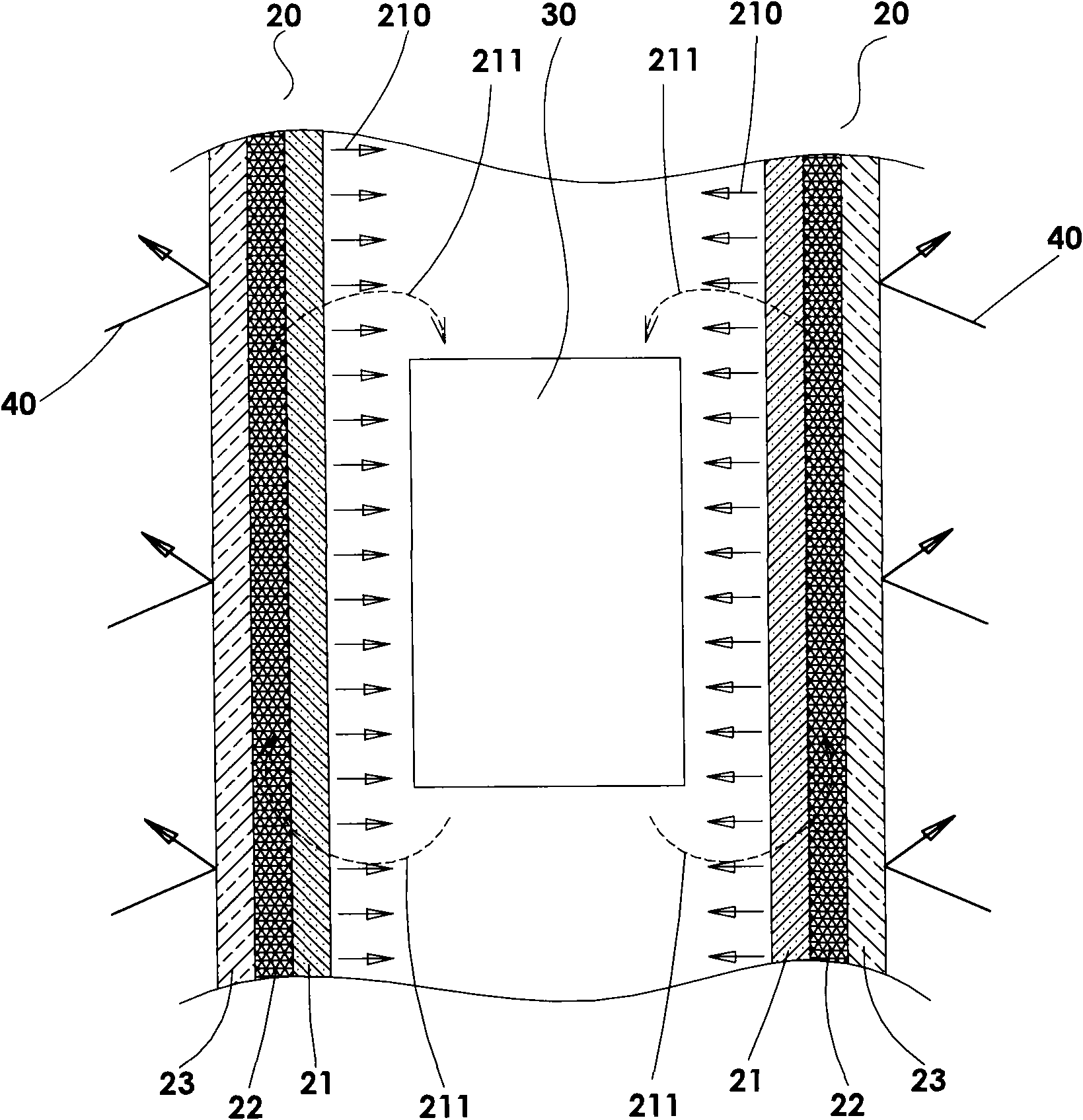

The invention discloses a high-strength oxidation-resisting anti-rust film which is prepared through the following steps: completing the preparation of an inner-layer material, a middle-layer material and an outer-layer material in an independent dispensing procedure; and then forming a three-layer compound film by extruding the inner-layer material, the middle-layer material and the outer-layer material in a multi-layer coextrusion mode by using an extrusion machine, wherein the inner-layer material contains a volatile corrosion inhibitor VCI (accounting for about 5wt% of the inner-layer material), through uniformly mixing the volatile corrosion inhibitor with a polyethylene PE master batch, an inner VCI anti-rust layer is formed; the middle-layer material contains 4,4'-Isopropylidenediphenol C12-15 alcohol phosphite (accounting for 3wt% of the middle-layer material), through uniformly mixing the 4,4'-Isopropylidenediphenol C12-15 alcohol phosphite with a polyethylene PE master batch, a middle bridging layer is formed; and the outer-layer material contains a polypropylene PP (accounting for 13wt% of the outer-layer material) and a metalized polypropylene MPP (accounting for 30wt% of the outer-layer material), through uniformly mixing the PP and the MPP with a polyethylene PE batch, an outer isolation layer is formed. The film disclosed by the invention has the economic effect of low manufacturing cost, and can be applied to metal product packaging; and meanwhile, the film also has the effects of weather fastness, tear resistance, antioxidation, waterproofing moisture-proofing and rust protection.

Owner:HON BOUW

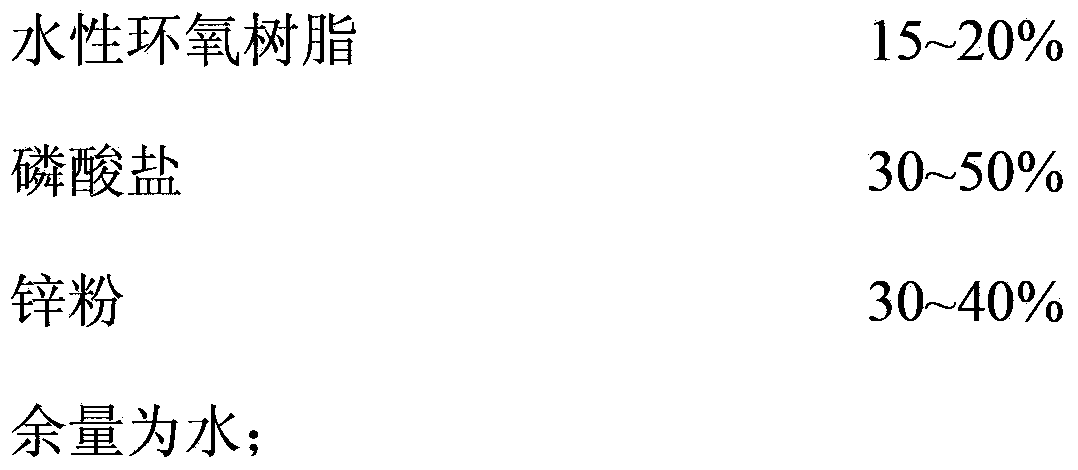

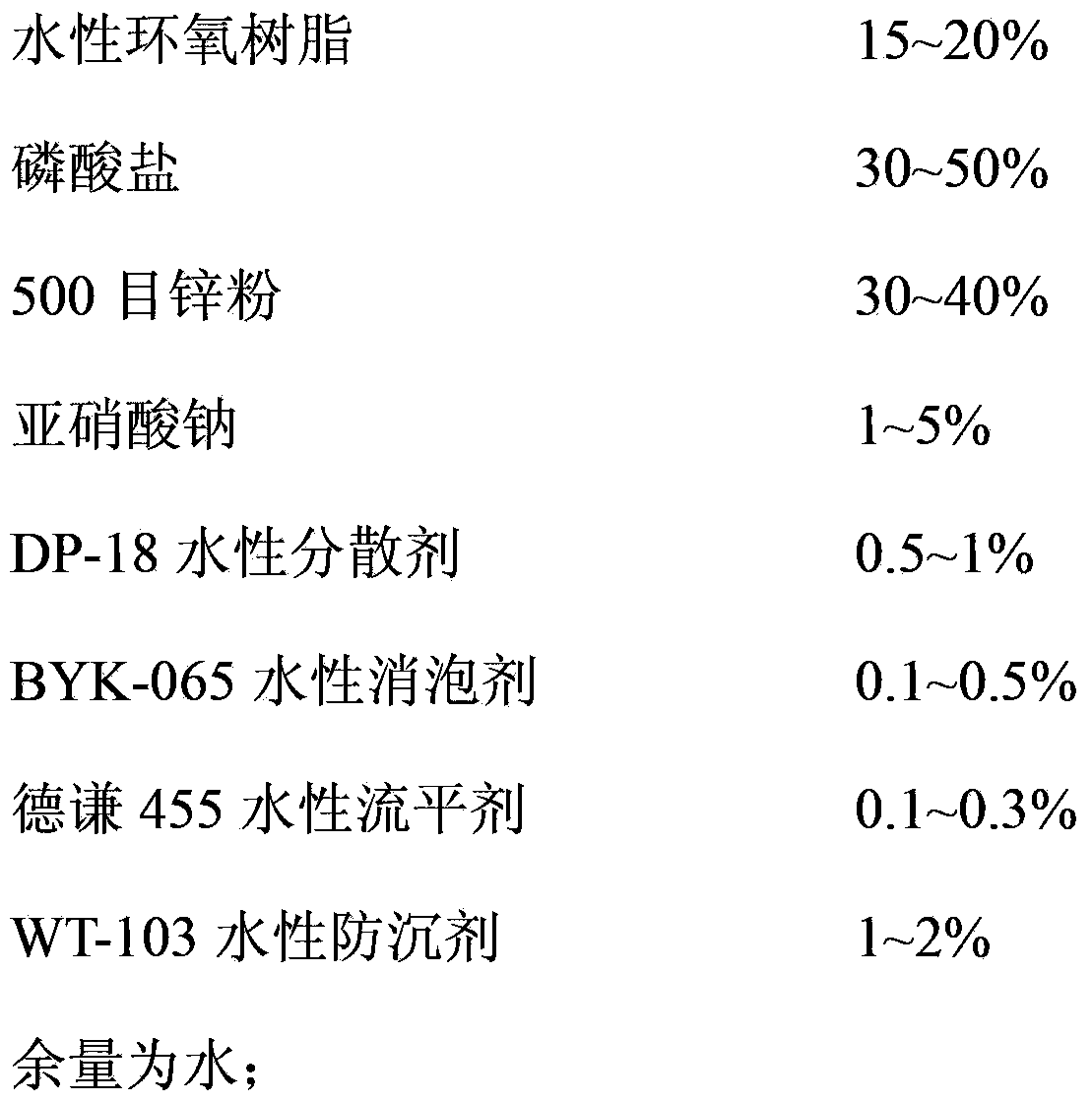

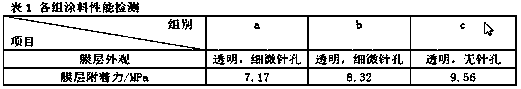

Waterborne epoxy phosphatic zinc dust antirust paint and its preparation method

InactiveCN103360903ALow toxicityImprove permeabilityAnti-corrosive paintsEpoxy resin coatingsChemistryFineness

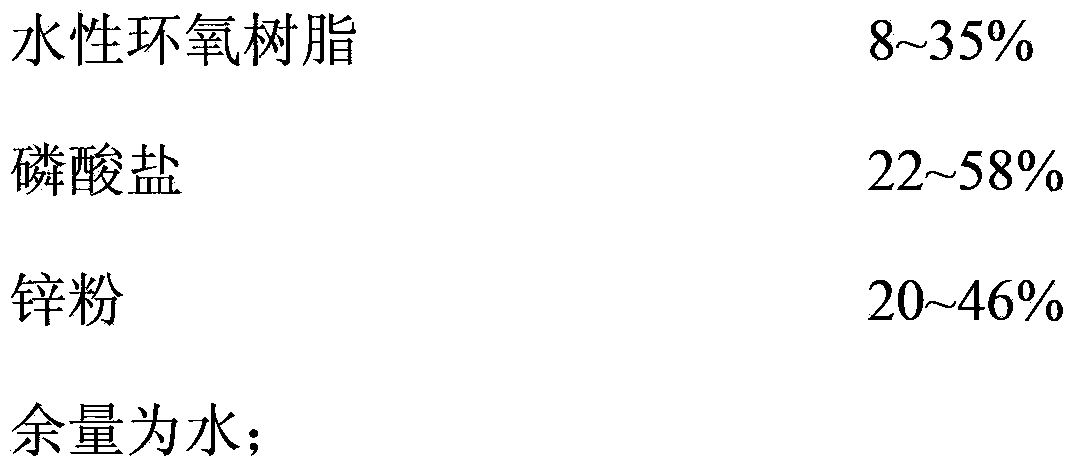

The invention relates to a waterborne epoxy phosphatic zinc dust antirust paint and its preparation method. The antirust paint is mainly composed of a component A and a component B: 1) the component A comprises the following ingredients: by weight, 8-35% of waterborne epoxy resin, 22-58% of phosphate, 20-46% of zinc dust and the balance water; and 2) the component B is a curing agent. The preparation method comprises the following steps: firstly mixing waterborne epoxy resin, phosphate, zinc dust, sodium nitrite, a dispersant and water according to the formula ratio, dispersing, and carrying out sand milling until the fineness is below 70 microns; adding other auxiliary agents into the obtained mixture and uniformly stirring, adjusting viscosity to 3-5 Pa, filtering and packaging to obtain the component B; and packaging the obtained component A and the component B according to the mass ratio.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

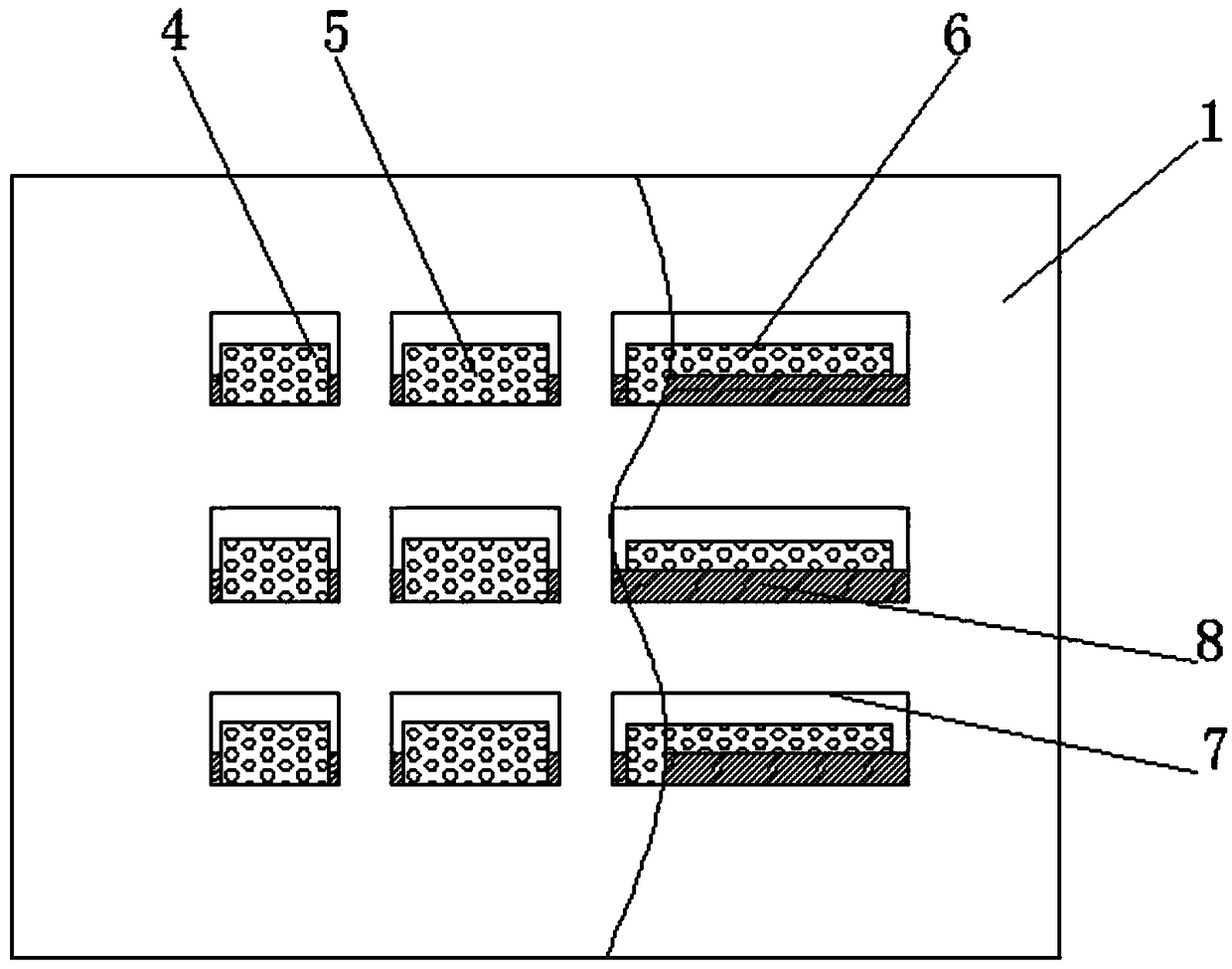

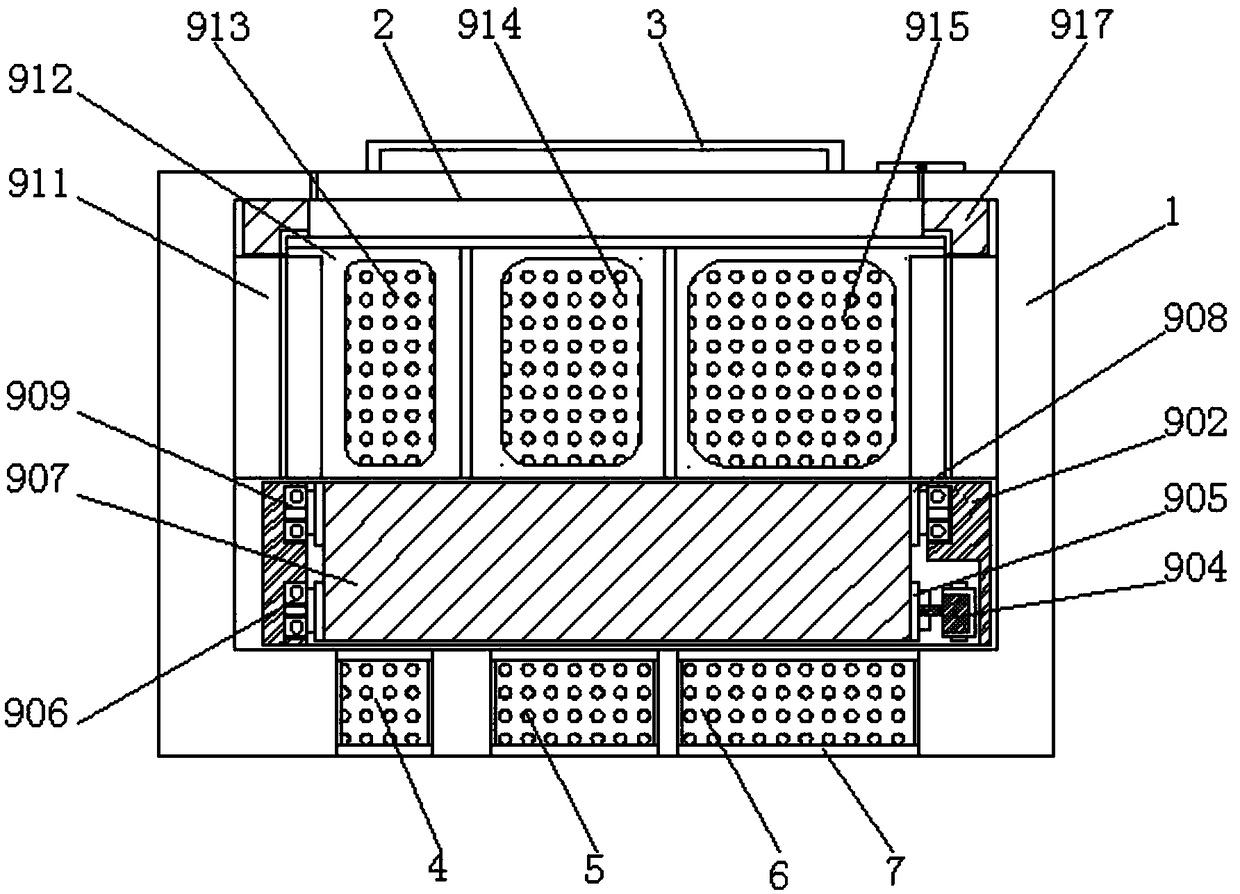

Rust-proof storage box for automobile parts

InactiveCN109368041APrevent rustTo achieve anti-rust effectPackaging under vacuum/special atmosphereDischarging meansRustOperations management

The invention discloses an rust-proof storage box for automobile parts. The rust-proof storage box comprises a storage box body. The surface of the storage box body is movably connected with an opening and closing door through hinges. A handle pull rod is fixedly connected to the surface of the opening and closing door. The front side of the storage box body is fixedly connected with small oil coating sponges; middle oil coating sponges are fixedly connected to one side, close to the small oil coating sponges, of the storage box body; and large oil coating sponges is fixedly connected to one side, close to the middle oil coating sponges, of the storage box body. According to the rust-proof storage box for the automobile parts, the fixed through holes matched with the size of the parts areselected, so that the parts of the same type can be transmitted in the same type of rail; and a rust-proof storage plate is divided into grids of different specifications through part baffle plates; when a part needs to be taken out, the opening and closing door is opened by manpower, the rust-proof storage plate is drawn out through movable holes, so that the effect of conveniently classifying and storing the parts by people is achieved.

Owner:嘉兴奥驰汽车零部件有限公司

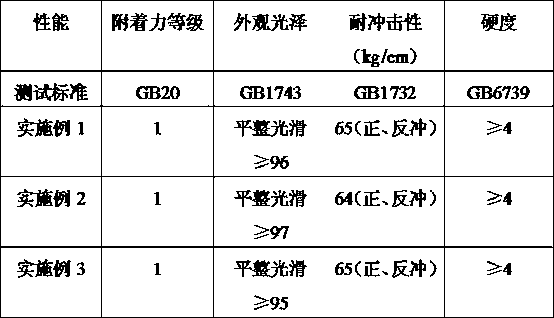

Electrostatic powder coating sprayed on tent support

ActiveCN103305093AImprove adhesionNot easy to fall offAnti-corrosive paintsEpoxy resin coatingsWaxEpoxy

The invention discloses an electrostatic powder coating sprayed on a tent support. The electrostatic powder coating comprises the following components in parts by weight: 25 to 40 parts of epoxy resin, 30 to 35 parts of polyester resin, 0.15 to 0.22 part of a flatting agent, 10 to 30 parts of titanium dioxide, 6 to 12 parts of calcium carbonate, 0.4 to 3 parts of wax powder, 0.8 to 3.2 parts of pigments and 0.5 to 2.5 parts of a promoter. The electrostatic powder coating sprayed on the tent support is good in adhesive force and hard to drop off after being well sprayed, an antirust effect can be realized by spraying little electrostatic powder coating, the surface of the electrostatic powder coating is smooth, the spraying thickness is reduced by 20 percent compared with that of the original powder coating, and the production cost is greatly reduced. The electrostatic powder coating sprayed on the tent support also has excellent weather resistance, high temperature resistance and abrasion resistance, and the like.

Owner:GUANGDONG UPAL DISPLAY TECH CO LTD

Water-based antirust preparation technique

The present invention relates to a water-base metal antirusting agent and its preparation method. Said preparation method includes the following steps: mixing 2 portions of triethylene tetraine and 5 portions of sebacic acid in a reactor, heating to 130deg.C-150deg.C, after 40min, adding 3 portions of tri-isopropanolamine in said reactor and uniformly stirring them for 10min so as to obtain the invented product.

Owner:冯为民

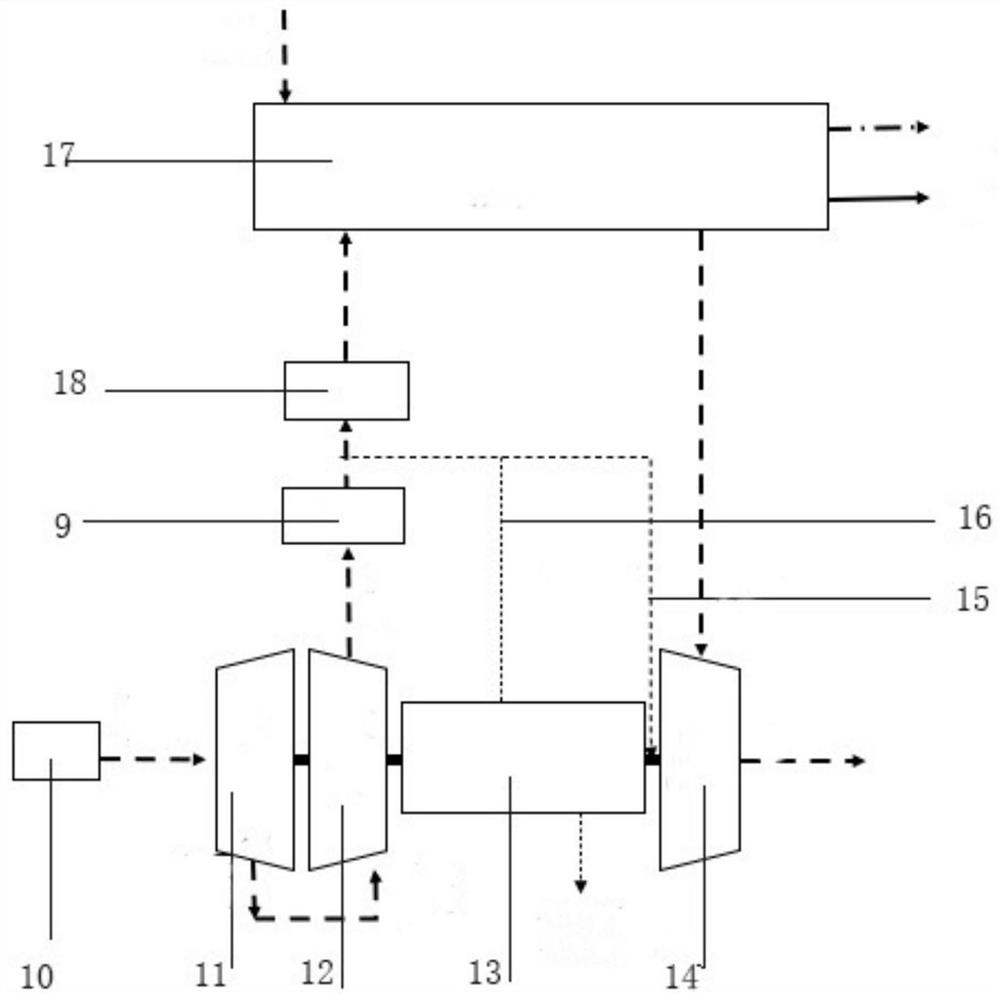

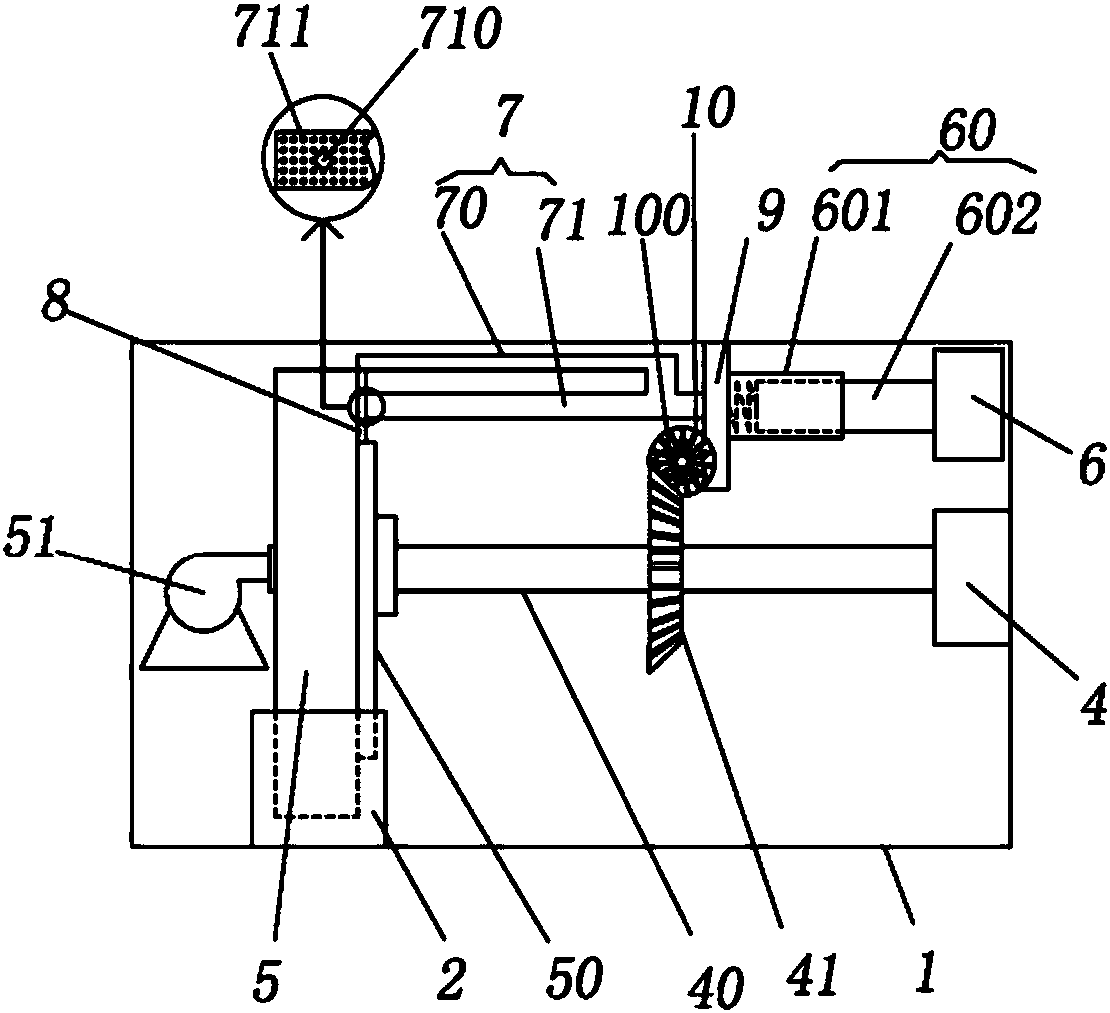

Automatic machining equipment for mass production of threaded rods

InactiveCN110293407AConvenient processing workHigh hardnessOther manufacturing equipments/toolsEngineeringThreaded rod

The invention relates to threaded rod machining equipment, in particular to automatic machining equipment for mass production of threaded rods. The automatic machining equipment is capable of saving manpower, high in safety and high in machining efficiency. According to the technical scheme, the automatic machining equipment comprises a bottom plate, a control box, a power main switch, an installation frame, an installation plate, a sliding rail, a sliding block, a clamp, a nut, a first bearing seat, a first rotating rod, a screw rod and the like; the control box is arranged in the middle of the top of the bottom plate and comprises a power supply module and a control module; the power supply module is connected with a switching power supply through a wire; and the control module is connected with the power supply module through a wire. According to the automatic machining equipment, a crank handle is rotated anticlockwise so as to drive the nut to move inwards through the screw rod, therefore, an iron rod is clamped through the clamp, and machining of the threaded rods is convenient; and through a tapping device, the iron rod can be tapped without using a threading die manually, so that manpower is saved.

Owner:叶玉芳

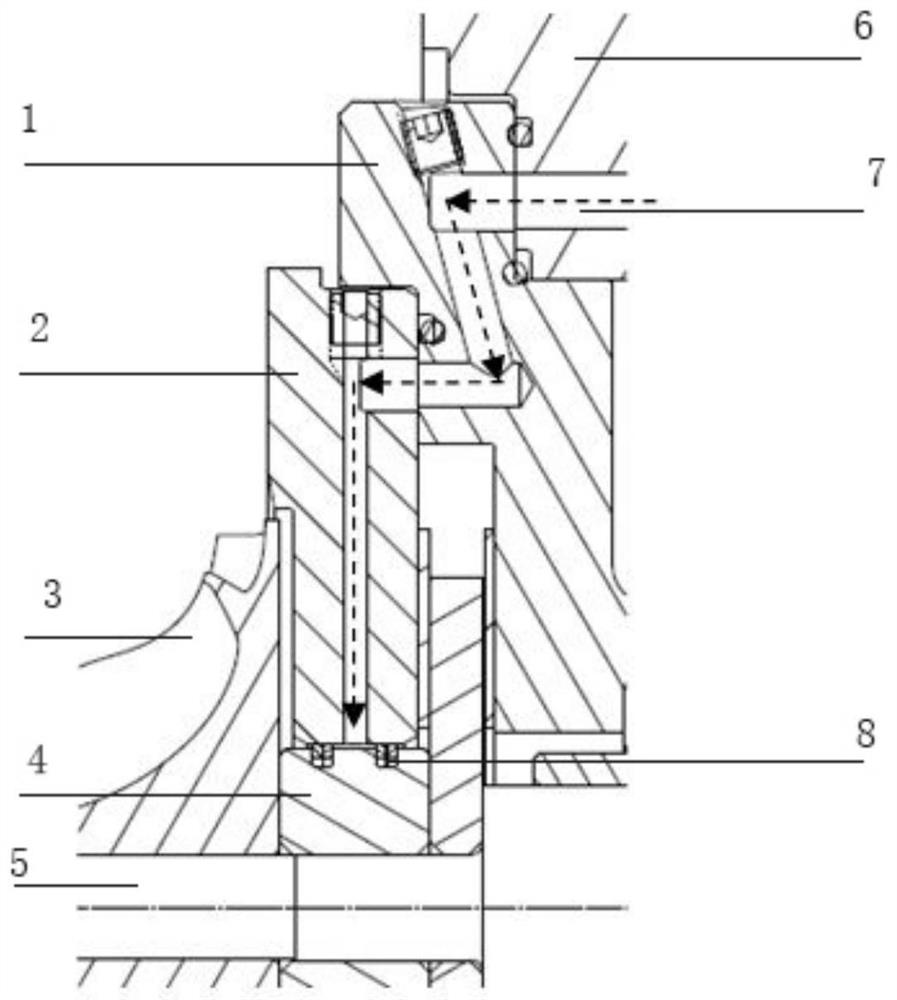

Air compressor system with turbo expander

InactiveCN112360569ALow manufacturing costSimple structureFinal product manufactureLeakage preventionElectric machineryAutomotive engineering

The invention discloses an air compressor system with a turbo expander. The air compressor system comprises a compressor, an intercooler, a humidifier, a motor, the turbo expander and a sealing air path; the intercooler and the humidifier are sequentially connected with an exhaust port of the compressor, and the humidifier is connected with a fuel cell; compressed gas exhausted by the compressor sequentially passes through the intercooler and the humidifier and then enters the fuel cell; the motor is arranged coaxial with the compressor; the turbo expander is arranged coaxial with the motor, and the turbo expander and the compressor are located at the two sides of the motor respectively; the turbo expander is configured to drive the compressor together with the motor under the drive of airexhausted by the fuel cell; and the sealing air path is connected between the motor and the turbo expander from an exhaust port of the intercooler, and the sealing air path can prevent air in the turbo expander from entering the motor. According to the air compressor system, rust-proof treatment on liable-to-be-rusted parts of the motor is avoided, and the manufacturing cost is reduced.

Owner:HYDROWELL (TAICANG) ENERGY TECH CO LTD

Nano-alumina-epichlorohydrin rubber composite tolerant coating for rusty surfaces

InactiveCN105838209AStrong adhesionTo achieve anti-rust effectWax coatingsConjugated diene hydrocarbon coatingsLacquerPolyethylene glycol

The invention discloses a nano-alumina-epichlorohydrin rubber composite tolerant coating for rusty surfaces, and relates to the technical field of industrial coatings .The nano-alumina-epichlorohydrin rubber composite tolerant coating for rusty surfaces is prepared from, by weight, 5-8 parts of nano-alumina, 50-55 parts of epichlorohydrin rubber, 12-16 parts of terpene resin, 10-15 parts of butadiene rubber, 8-11 parts of mineral flour, 6-10 parts of carnauba wax, 6-10 parts of polyoxyethylene, 5-8 parts of sodium alginate, 5-8 parts of polyethylene glycol 400, 4-6 parts of iron-titanium compound powder, 4-6 parts of sodium polyacrylate, 3-5 parts of trioctyl citrate, 3-5 parts of nano-rubber powder, 2-4 parts of poloxamer, 1-2 parts of coal tar and 100-150 parts of water .The coating can be directly sprayed to rusty metal surfaces without polishing or deoiling treatment, and rusty layers are passivated to achieve the rust protection effect; besides, curing time is short, a formed coating film is large in adhesion force and does not effloresce or shed or the like, and the service life is long.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Anti-rust polyethylene film material and preparation method thereof, as well as anti-rust bag

The invention discloses an anti-rust polyethylene film material and a preparation method thereof, as well as an anti-rust bag. The anti-rust polyethylene film material is prepared from the following raw materials in percentage by weight: 60-70 percent of linear low-density polyethylene, 20-30 percent of high-pressure polyethylene, 2-5 percent of flame-retardant masterbatches and 1-5 percent of anti-rust masterbatches. The preparation method of the anti-static polyethylene film material comprises the following steps: respectively weighing all the components in part by weight; putting all the components in an extruder for extrusion, wherein the temperature of a first zone of the extruder is 145-155 DEG C, the temperature of a second zone is 150-160 DEG C, the temperature of a third zone is 150-160 DEG C, the temperature of a die head of the extruder is 150-170 DEG C, the rotating speed of a lead screw is 100-120 r / min, and the host frequency is 12-14 HZ; after extrusion, cooling, formingand winding to obtain the anti-rust polyethylene film material. As the anti-rust masterbatches are added, the anti-rust polyethylene film material disclosed by the invention has a special anti-rust smell; particles in the anti-rust masterbatches are gasified into gas, and the anti-rust gas can form a protective film on the metal surface to cut off the possibility of contact metal ions with waterand oxygen. Therefore, an anti-rust effect is achieved.

Owner:苏州汤志塑料制品有限公司

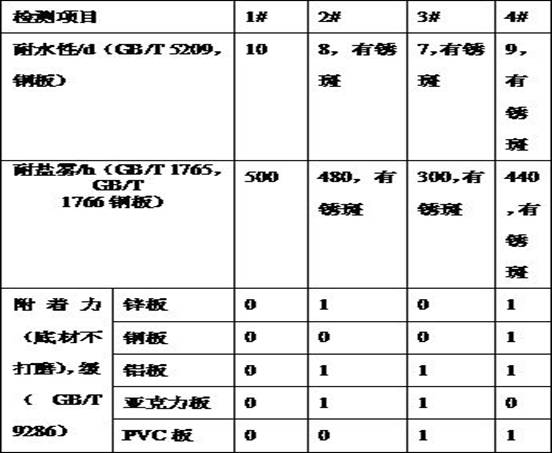

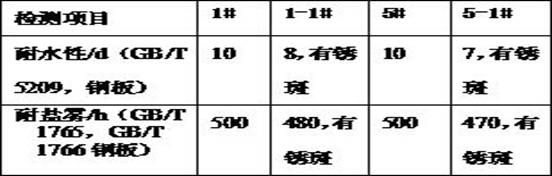

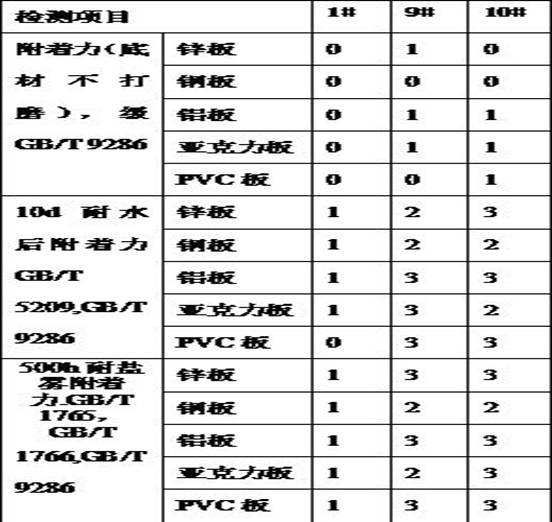

Multipurpose primer-topcoat water-based coating and preparation method thereof

The invention relates to a coating and a preparation method thereof, and concretely relates to a multipurpose primer-topcoat water-based coating and a preparation method thereof. The multipurpose primer-topcoat water-based coating comprises 38-52 parts of a self-drying water-based acrylic emulsion, 1-2 parts of ethylene glycol monobutyl ether, 1-2 parts of dipropylene glycol monomethyl ether, 1-2 parts of texanol, 0.2-0.7 part of a dispersant, 1-3 parts of a siloxane-based coupling agent, 1-3 parts of an epoxy phosphate polymer, 1-3 parts of a zinc molybdate modified pigment, 2-5 parts of a calcium ion exchange type antirust pigment, 2-5 parts of a calcium phosphate based anti-corrosion inhibitor, 2-10 parts of siloxane modified nano mica powder, 2-6 parts of superfine talcum powder, 2-6 parts of superfine barium sulfate, 11-23 parts of titanium dioxide, 0.1-0.5 part of organic soil, 0.3-0.8 part of a flash rust inhibitor, 0.2-1 part of a thickening agent and 0.1-34 parts of deionized water. The coating is widely applied, and the adhesive force can be measured to be 0-1 level in a gridding manner on a steel plate, an aluminum plate, a galvanized plate, an acrylic plate and a PVC plate subjected to low surface treatment.

Owner:GUANGDONG YATU CHEM

Marine atmospheric saline alkali zone aqueous zinc strip rust free anticorrosive paint

The invention relates to a marine atmospheric saline alkali zone aqueous zinc strip rust free anticorrosive paint. The paint comprises 10-26% of deionized water, 0.1% of a mildew inhibitor, 0.8% of a dispersant, 0.5% of an antifoaming agent, 2.5% of a film forming assistant, 2.5% of an antifreeze agent, 0.2% of a neutralizer, 0.2% of a wetting agent, 0.2% of a foam inhibitor, 0.1% of a leveling agent, 1% of a corrosion agent, 1% of a corrosion inhibitor, 2% of a flash-rust inhibitor, 10% of iron oxide red or composite iron-titanium powder, 5-10% of aluminum triphosphate, 1-5% of rutile titanium dioxide, 9% of wollastonite, 5-10% of wet sericite, 40-60% of a vinyl versatate copolymer improved resin and 0.5-1% of a swelling reducing and thickening agent. The marine atmospheric saline alkali zone aqueous zinc strip rust free anticorrosive paint prepared by adopting a technical scheme in the invention has the advantages of omission of large rust removal engineering before enterprise coating, saving of huge cost for the enterprise, anticorrosion effect increase and very good market prospect.

Owner:张文彬

Water-based corrosion inhibition type rusted anti-rust coating and preparation method thereof

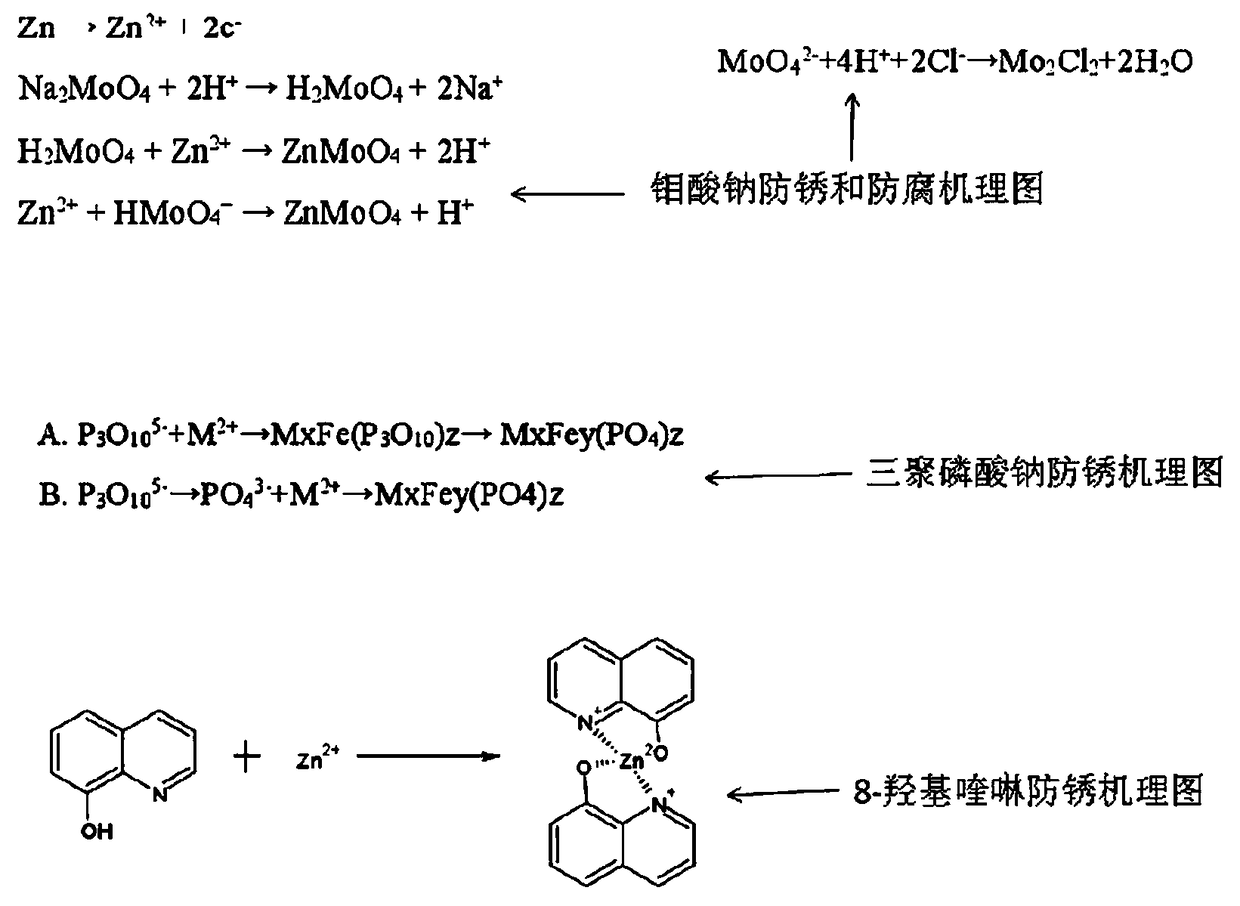

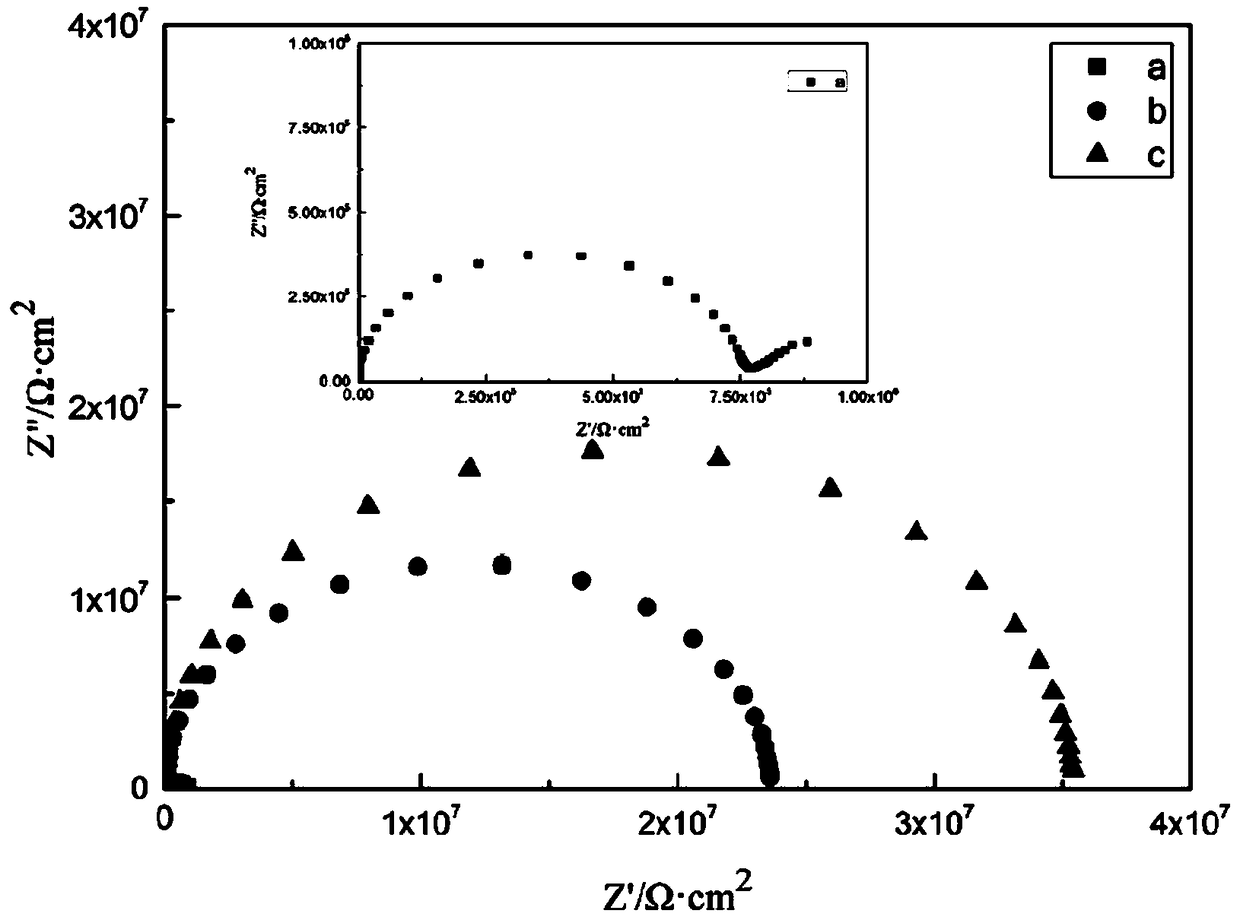

ActiveCN109337514AImprove anti-corrosion and anti-rust performanceGood dispersionAnti-corrosive paintsEpoxy resin coatingsEpoxySolubility

The invention relates to the field of a coating, and discloses a preparation method of a water-based corrosion inhibition type rusted anti-rust coating. According to the invention, cellulose-based aerogel with a porous structure is prepared by adopting a freeze-drying method; water solubility of sodium molybdate and sodium tripolyphosphate is utilized, and in the process of preparing the cellulose-based aerogel, the sodium molybdate and the sodium tripolyphosphate are added, so that the sodium molybdate and the sodium tripolyphosphate which have a rusted anti-rust function are loaded on the cellulose-based aerogel; and insolubility between 8-hydroxyquinoline and water is utilized, the 8-hydroxyquinoline is fed into pore passages of the cellulose-based aerogel by adopting an ultrasonic oscillation method, so that the 8-hydroxyquinoline with a rusted anti-rust function is positioned inside the pore passages. The cellulose-based aerogel with three rusted anti-rust functional materials isfilled into water-based epoxy resin, and the rusted anti-rust materials are utilized to be chelated with metal to generate a passivation film to protect a metal matrix, so that the anti-corrosion anti-rust ability of the coating is improved greatly.

Owner:SHENYANG SHUNFENG IND GRP CO LTD

Water soluble metal antirusting agent and preparation method thereof

The invention provides water soluble metal antirusting agent. The water soluble metal antirusting agent comprises the following constituents in part by mass: 7 to 10 parts of triethanolamine, 3 to 5 parts of zinc chloride, 2 to 3 parts of sodium borate, 1 to 2 parts of sodium methoxide, 4 to 6 parts of sodium carbonate, 3 to 5 parts of stannous mono-sulphate, 1 to 2 parts of diethanol amine, 1 to 2 parts of isopropyl alcohol, 10 to 15 parts of ethyl alcohol, and 70 to 80 parts of water. The invention further provides a preparation method of the antirusting agent. By soaking metal work pieces in the water soluble metal antirusting agent, a layer of oxide protective film can be formed on the surface of metal, the tissue structure is dense, and particles are fine, so that the effect of rust protection is achieved; the water soluble metal antirusting agent is short in film formation time and good in drying capacity, and can form a film in 1 to 2 minutes only; the water soluble metal antirusting agent can ensure that metal keeps rustless within 6 months in normal environment.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

Composite material structure and production method thereof

PendingCN109878149AImprove resistance to yieldingHigh strengthSynthetic resin layered productsMetal layered productsFiberCarbon fibers

The invention discloses a composite material structure and a production method thereof. The composite material structure comprises a base body, wherein a carbon fiber material and a prereg material cover the surface of the base body; the prereg material is immersed into the carbon fiber material to form a composite layer. The production method comprises the following steps of 1, preparing the basebody, the carbon fiber material and the prereg material; 2, coating the base body with the carbon fiber material; 3, brushing the prereg material onto the base body coated with the carbon fiber material so that the prereg material is immersed into the carbon fiber material to form a composite layer; performing drying. The composite material structure has the advantages that the yield resistance is high; the intensity is high; the tensile intensity is enhanced; the weight becomes light; meanwhile, the anti-corrosion performance is realized; in the processing and manufacturing process, the steel materials can be greatly saved, so that the material can be widely applied to various fields.

Owner:海添琪

Anti-rust gasket

The invention discloses an anti-rust gasket. The anti-rust gasket is characterized in that the gasket is of an ellipse structure; a round hole is formed in the middle of the gasket; four evenly-distributed rectangular notches are formed in the inner side of the round hole; and four round oil leakage holes are evenly distributed in the anti-rust gasket. The anti-rust gasket has the beneficial effects of being simple in structure, reasonable in design, wide in application range, low in cost and easy and convenient to operate.

Owner:NANTONG DILONG KNITTING GARMENT

Preparation method of carbonyl iron powder based rust-proof powder for producing integrally-formed inductor

ActiveCN111063535AImprove dielectric strengthGood flexibilityInductances/transformers/magnets manufactureSilicone resinCarbonyl group

The invention discloses a preparation method of carbonyl iron powder based rust-proof powder for producing an integrally-formed inductor. The preparation method comprises the following steps: phosphating carbonyl iron powder; dissolving epoxy resin and organic silicon resin into a glue solution by using acetone; diluting a special insulation treating agent with acetone; diluting a film-forming agent with acetone; and adding the glue solution into the phosphatized carbonyl iron powder and stirring into slurry, adding a special insulation treating agent solution and continuing stirring to a uniform state, adding a film-forming agent solution and continuing stirring to a uniform state, carrying out granulating, airing and drying the particles, then adding zinc stearate and carrying out stirring to a uniform state, and carrying out sieving and screening to obtain the carbonyl iron powder based rust-proof powder. By adding the special insulation treating agent and the film-forming agent, ahigh-insulation adhesive film with considerable strength is formed on the surfaces of carbonyl iron powder particles, environmental erosion can be effectively resisted, the product directly achieves an anti-rust effect, the production cycle can be shortened, the production efficiency can be improved, and the production cost can be reduced.

Owner:深圳市艺感科技有限公司

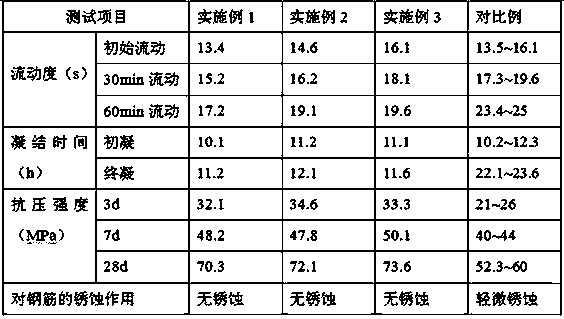

Preparation method of grouting material

The invention discloses a preparation method of a grouting material and belongs to the field of buildings. A water reducing agent with relatively good water solubility and surface activity is preparedby utilizing papermaking black liquid and a lubricating effect of bubbles is generated so that the flowability of concrete is improved and the workability becomes good; the air entraining content ofthe concrete is increased due to the foaming property and the strength is reduced; meanwhile, modification is carried out, and almost reducing sugars are oxidized in an oxidization process, so that the final condensation time is improved; free groups are formed by hydrogen peroxide and grafting polymerization reaction is easy to carry out, so that the content of carboxyl is increased and the waterreduction rate is improved, and furthermore, the strength of the concrete is improved; anionic and non-ionic surfactants are also added and compounded, so that a sulfonation reaction product is moredensely adsorbed on the surfaces of cement particles. By adopting the preparation method disclosed by the invention, the problems of a current grouting material that the antirust performance is relatively poor, the strength is not high enough and the condensation time of slurry under a negative-temperature environment is long are solved.

Owner:俞小峰

Antirust packaging material and preparation method thereof

The invention discloses an antirust packaging material and a preparation method thereof. The antirust packaging material comprises the following components in parts by weight: 50-100 parts of a thermoplastic or elastomer polymer base material and 0.1-50 parts of an active material, wherein the active material comprises one or more of metal micro-powder, metal oxide micro-powder and carbon micro-powder. The thermoplastic or elastomer polymer base material and the active material are used as main raw materials, the prepared antirust packaging material has the advantages of no gas volatilization,long-term protection, visible failure, recyclability, easiness in recovery and the like; moreover, the prepared antirust packaging material not only can be suitable for protection of various preciousmetal materials including copper, nickel and silver and ferrous metal materials mainly including iron and steel, but also can be used for long-term protection of electronic devices, electromechanicalautomation equipment and high-end intelligent equipment containing various metal materials.

Owner:沈阳防锈包装材料有限责任公司

Support

InactiveCN106583317ATo achieve the purpose of cleaningTo achieve anti-rust effectDrying gas arrangementsLiquid spraying apparatusKnife handlesEngineering

A support comprises a support body, fixing holes, rollers, tracks, a knife handle fixing device, a blade fixing device and a cavity, wherein the rollers are fixed by a self-locking function; a knife is mounted and fixed on the support; a spray cleaning device sprays a cleaning fluid onto the knife for cleaning; a dirt layer is dispersed, emulsified and stripped to achieve the cleaning purpose through direct and indirect actions of cavatition, acceleration and straight flow of ultrasonic waves in liquid on liquid and dirt; and the knife is subjected to hot-air drying through a hot-air drying device, compressed air is utilized to atomize anti-rust oil, the atomized anti-rust oil is uniformly sprayed onto the surface of the knife, and accordingly, the knife can achieve an anti-rust effect.

Owner:ZHONGSHAN YUANHENG HOUSEHOLD ARTICLES

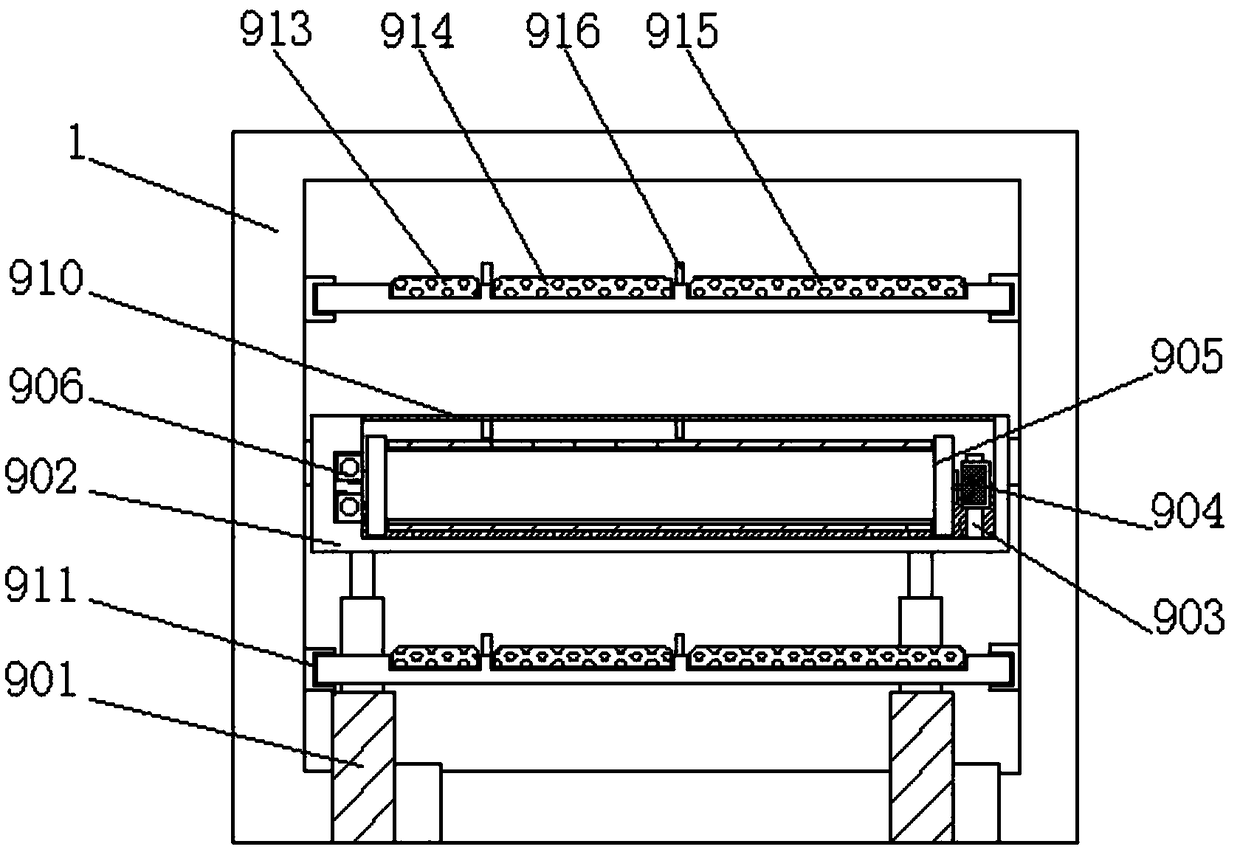

Preparation method for television back plate simple in process and good in anti-rust effect

InactiveCN109719019ASimple processImprove rust resistanceTelevision system detailsPretreated surfacesZincRust

The invention relates to the technical field of television back plate machining, in particular to a preparation method for a television back plate simple in process and good in anti-rust effect. The preparation method comprises the following steps that a, dust removal is performed on the surface of a cold-rolled plate, and then drying is performed; b, anti-rust paint is uniformly sprayed on one side face of the cold-rolled plate; c, punch forming is performed on the cold-rolled plate to obtain a formed television back plate; d, paint drying treatment is performed on the outer side face of thetelevision back plate; e, a conductive region on the outer side face of the television back plate is cleaned firstly, then covering protection is performed on the periphery of the conductive region, then conductive paint is sprayed to the conductive region, and drying is performed to obtain a finished product of the television back plate. According to the preparation method, the zinc plating process is omitted, the production working procedure is greatly simplified, so that the production cost is reduced by about 10%, meanwhile, the anti-rust effect and the conductive performance of the television back plate can be ensured, and the problem that in the prior art, a punch notch located at the edge of the lower end of the television back plate is prone to oxidization and rusting is solved.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

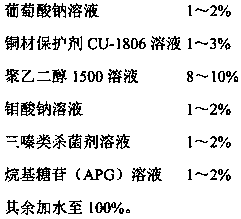

Environmentally-friendly safety type copper material cleaning protection agent and preparation method thereof

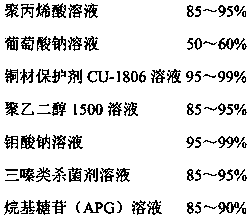

The present invention relates to the field of chemical cleaning agents, particularly to an environmentally-friendly safety type copper material cleaning protection agent and a preparation method thereof, wherein the environmentally-friendly safety type copper material cleaning protection agent comprises, 1-2% of a polyacrylic acid solution, 1-2% of a sodium gluconate solution, 1-3% of a copper material protection agent CU-1806, 8-10% of a polyethylene glycol 1500 solution, 1-2% of a sodium molybdate solution, 1-2% of a triazine-based bactericide solution, 1-2% of an alkyl glycoside (APG) solution, and the balance of water. According to the present invention, the environmentally-friendly safety type copper material cleaning protection agent is prepared by using the organic acid, the surfactant, the copper material protection agent and the bactericide as the main raw materials through the scientific processing technology, does not require the rinsing after the cleaning, and can achieve the ultra-long copper material protection requirement, wherein the surface of the part cleaned with the environmentally-friendly safety type copper material cleaning protection agent has characteristics of no white spot and complete brightening; and the environmentally-friendly safety type copper material cleaning protection agent is weakly alkaline, can perform the cleaning and the protection in one step so as to solve the difficult problem of complex cleaning and protection, and is especially suitable for the cleaning and antirust of a variety of copper materials.

Owner:北京洁航箭达环保科技有限公司

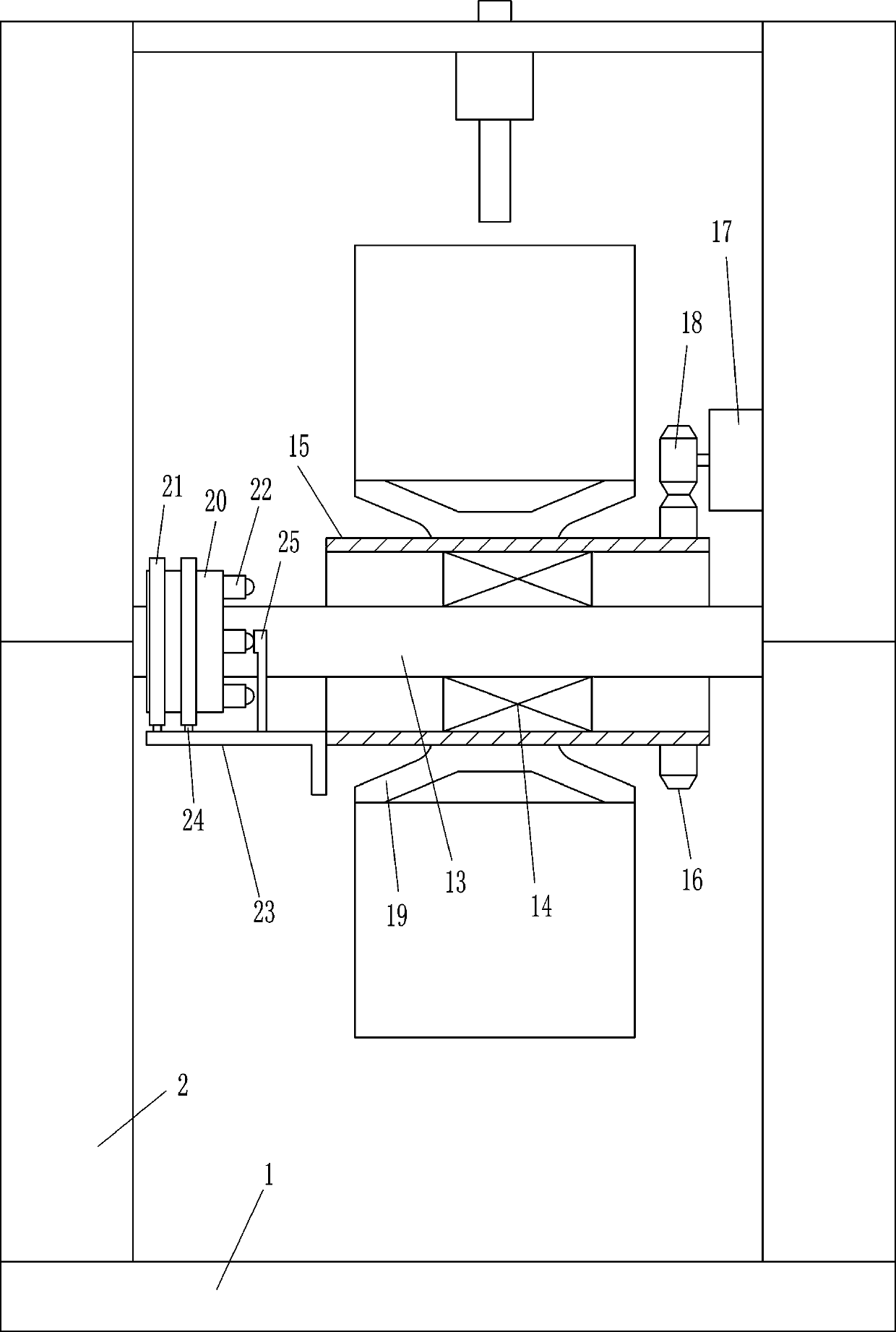

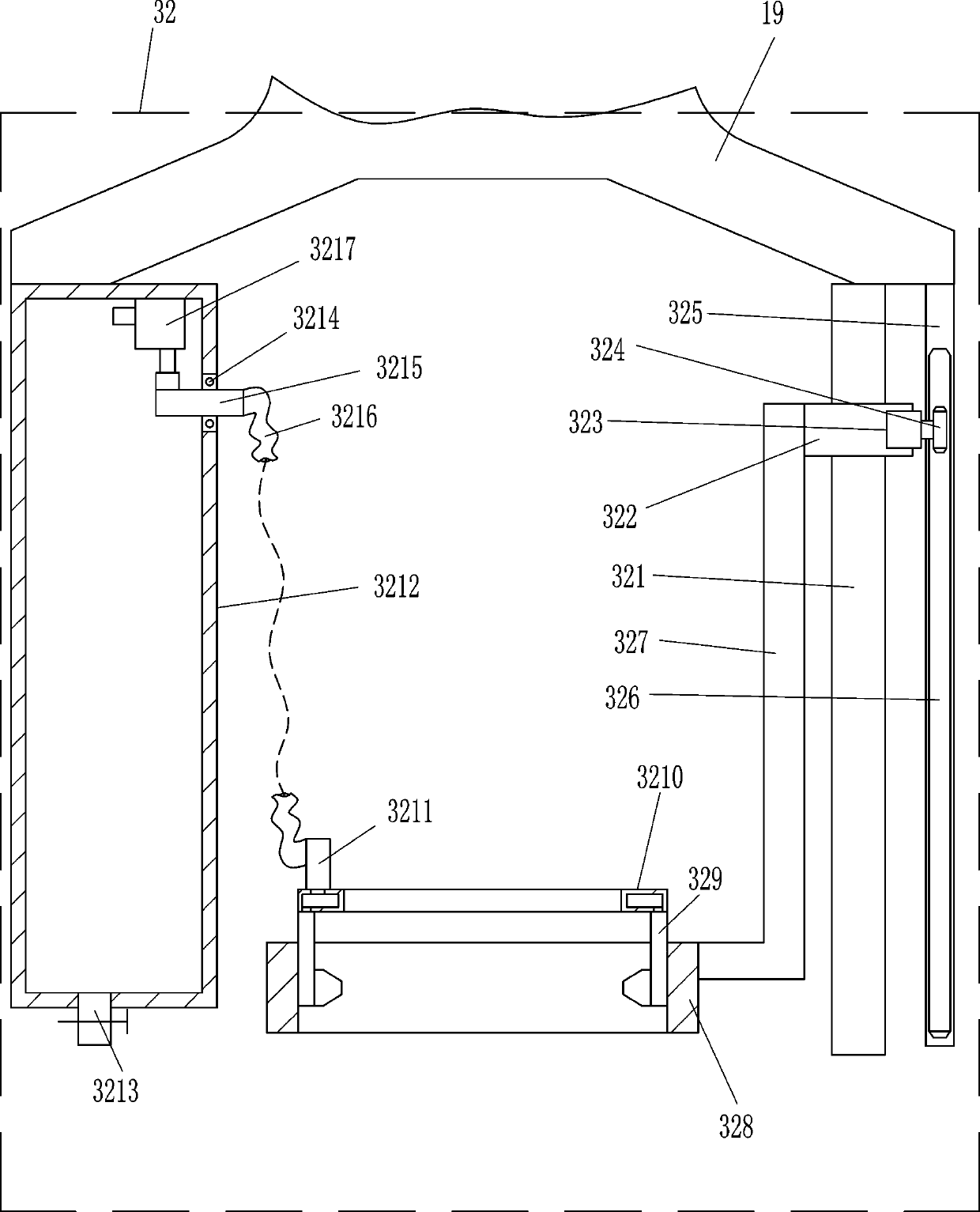

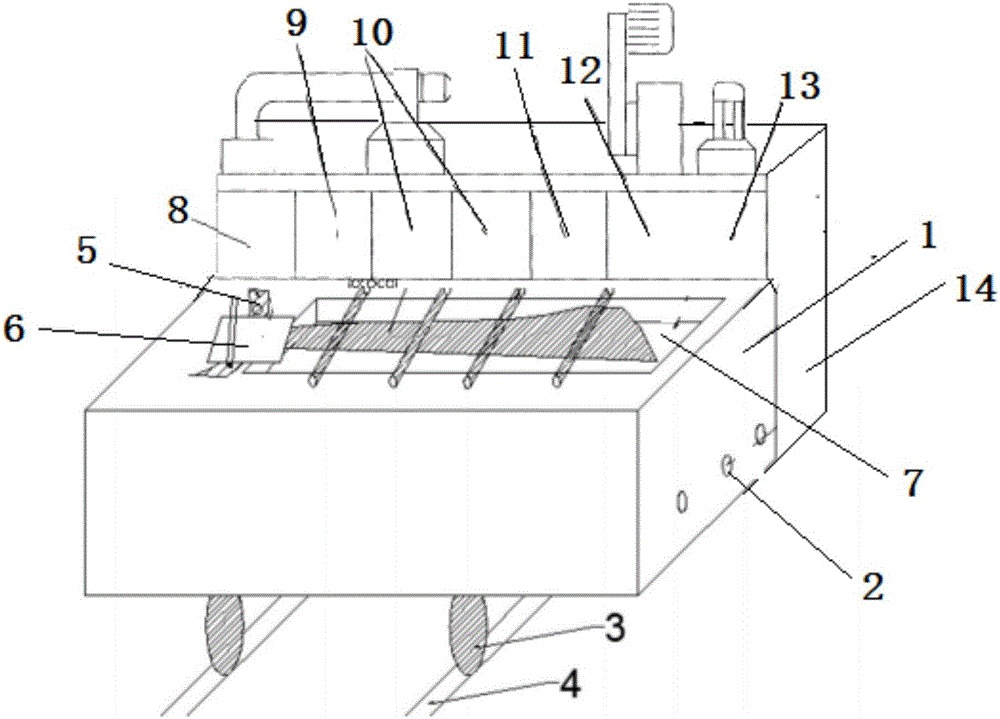

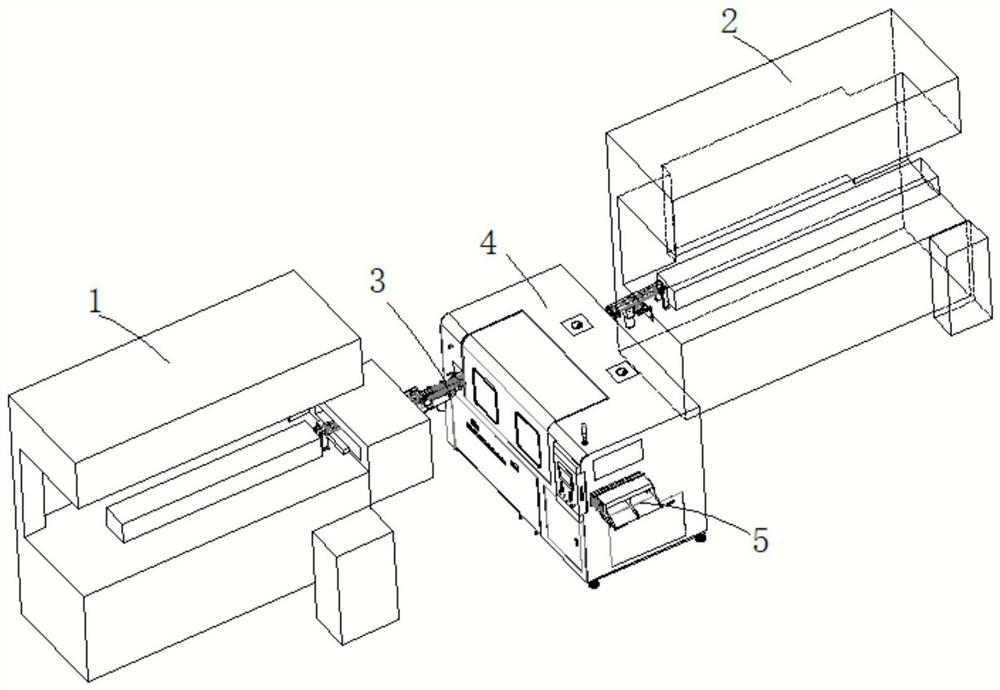

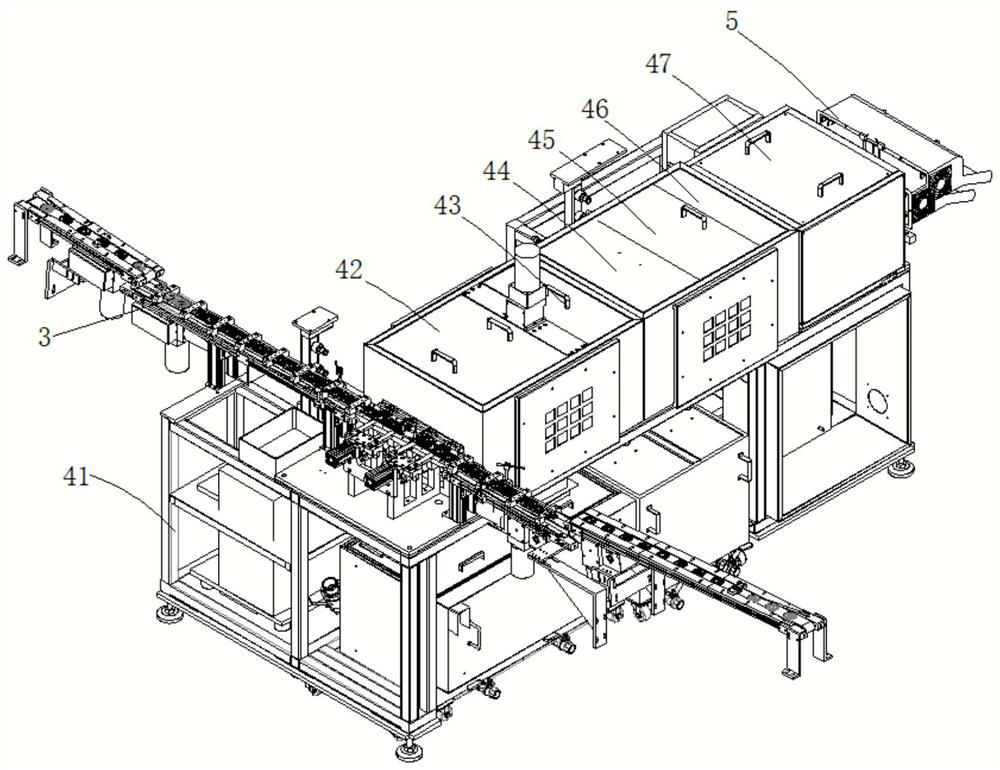

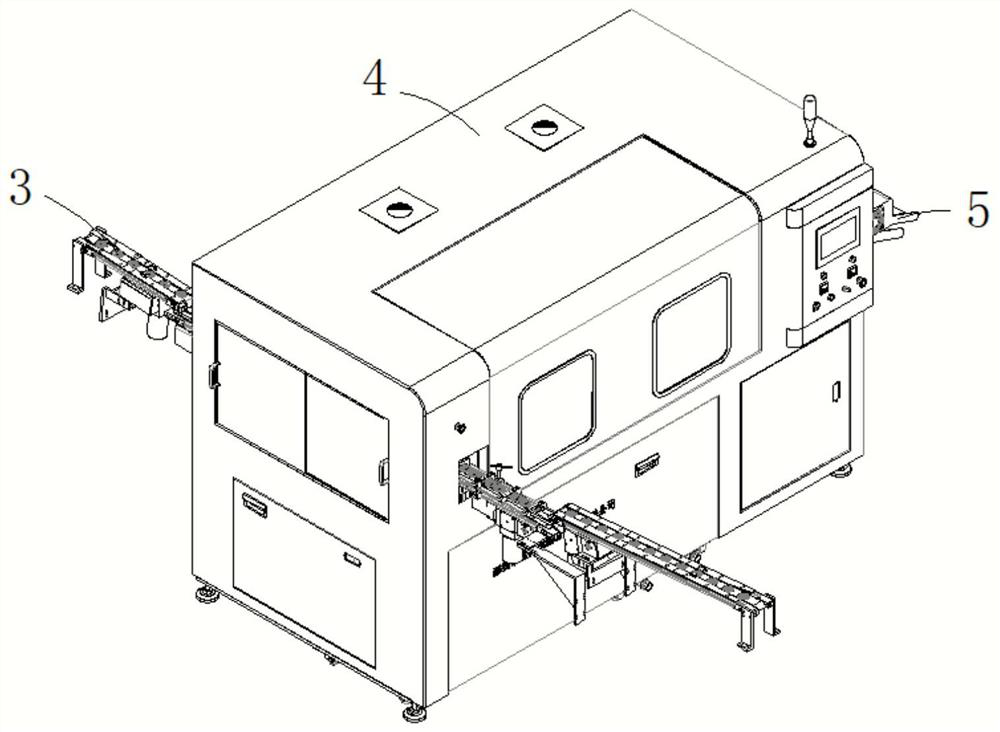

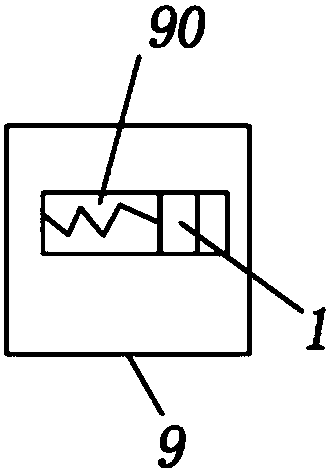

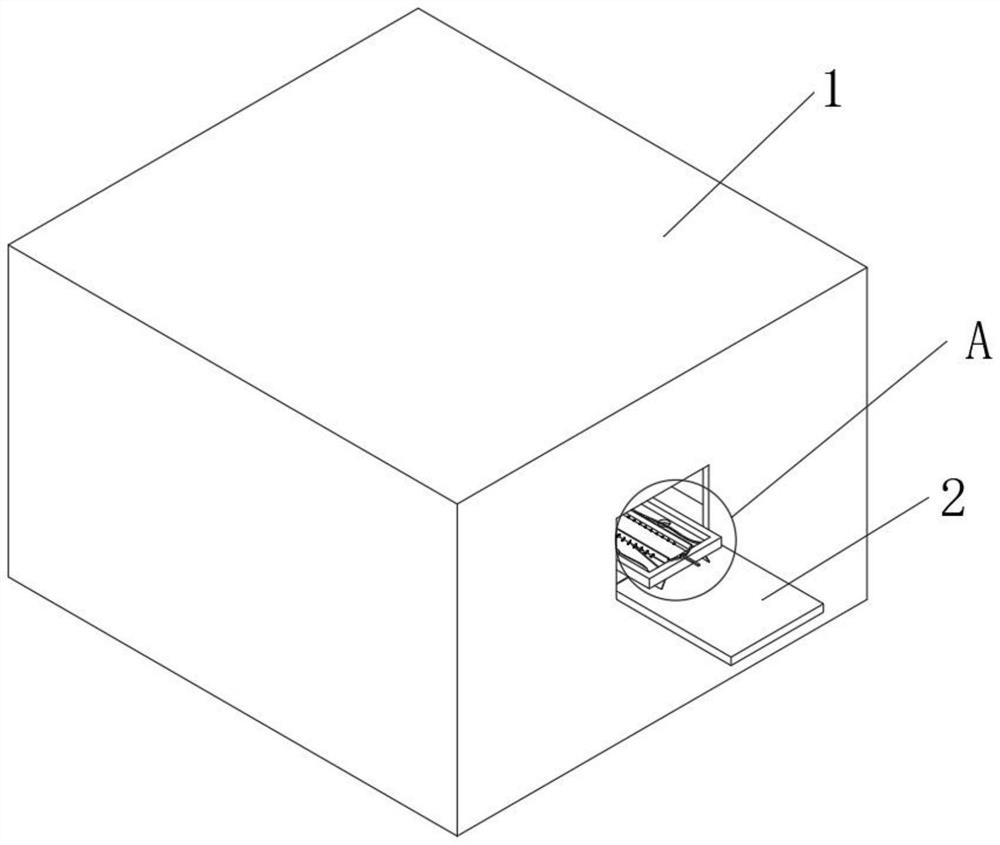

An efficient and environmentally friendly cleaning equipment for stamping parts

ActiveCN112295998BImprove work efficiencyGuaranteed cleaning effectDrying gas arrangementsCleaning using liquidsPunch pressProcess engineering

The invention relates to the technical field of stamping cleaning, in particular to a high-efficiency and environment-friendly cleaning equipment for stamping parts, comprising a first punch, a second punch, and an environment-friendly washing device, wherein the first punch and the second punch are distributed on the left and right sides of the environment-friendly washing device. On the other hand, the discharge ends of the first punch press and the second punch press are fixedly connected with conveying rails, and the tail ends of the conveying rails are connected with the conveying rails inside the environmental protection washing equipment. The environmental protection washing equipment includes a frame, a washing machine components, pre-water removal components, passivation liquid components, water spray components, complete water removal components and baking components. In the present invention, the punched parts punched by the first punch and the second punch are transported to the inside of the environmental protection flushing equipment through the conveying track, and the high-pressure cleaning, pre-water removal, passivation liquid addition, clear water, baking and cooling processes are completed, and the punching process is completed. After the stamping is completed, the parts are directly and completely cleaned and meet the anti-rust standard. The automatic operation not only saves energy and protects the environment, but also improves the work efficiency.

Owner:深圳市鑫昌顺精密机械有限公司

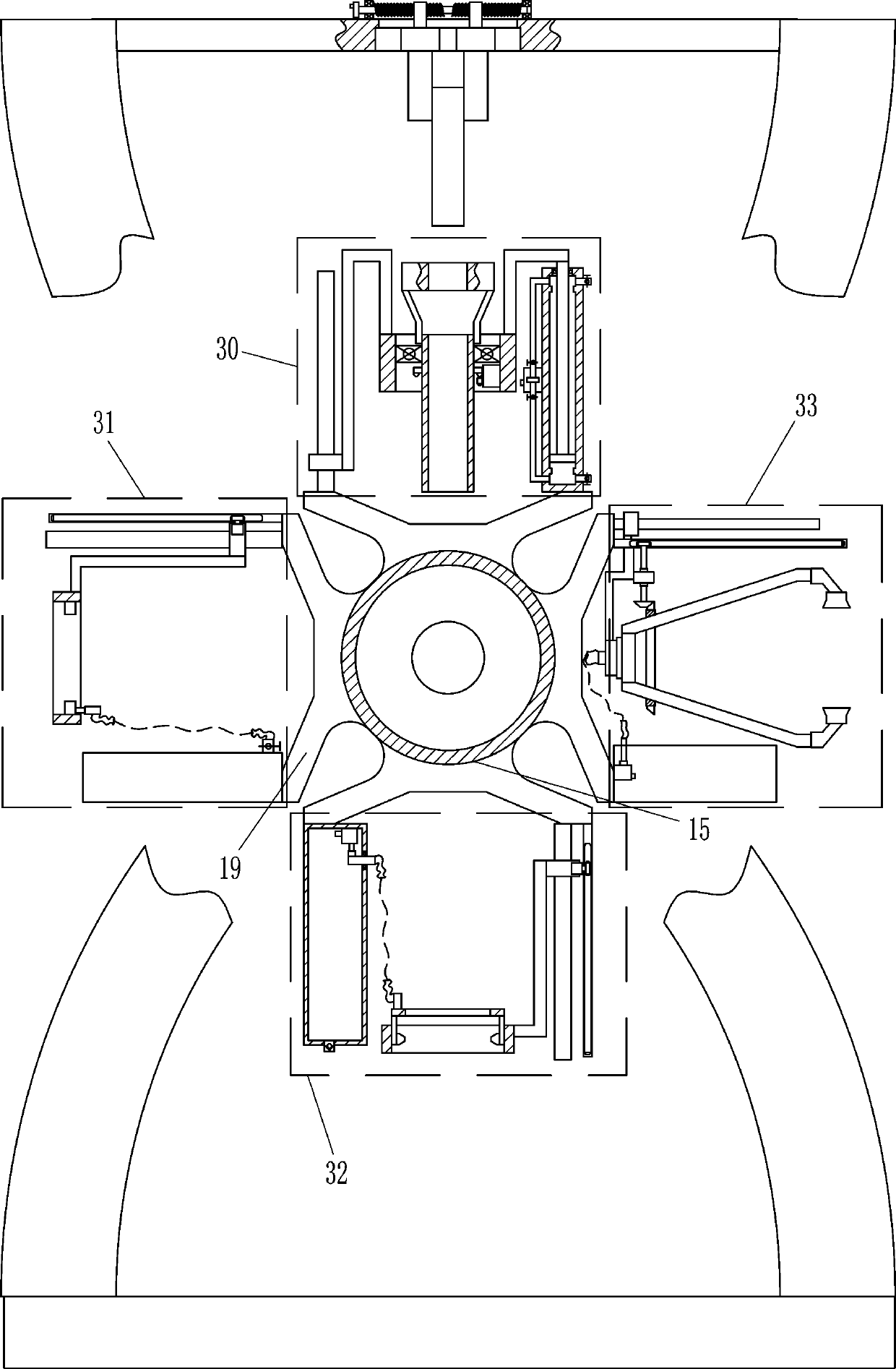

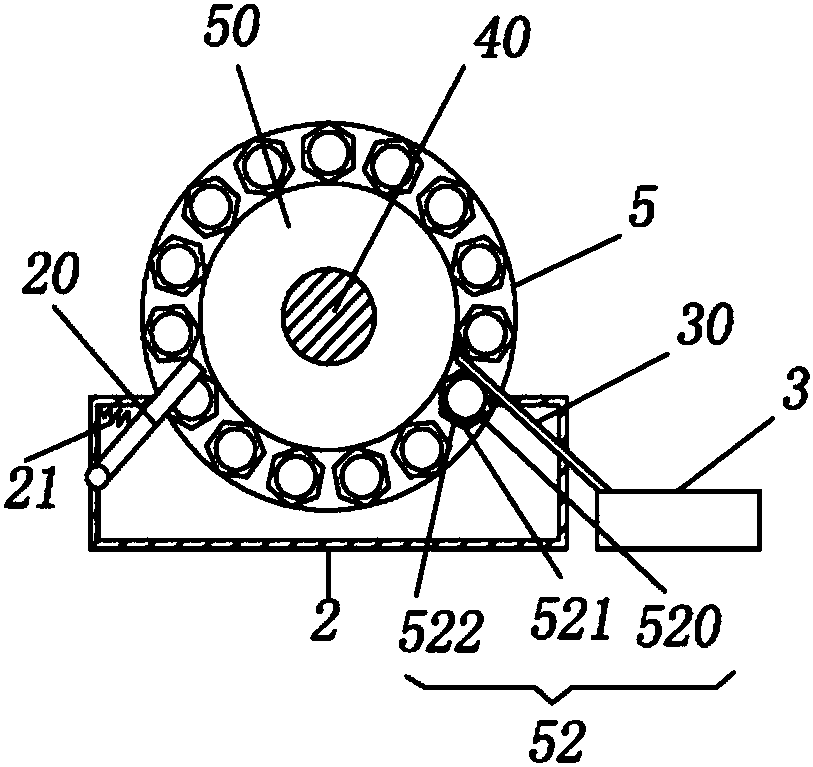

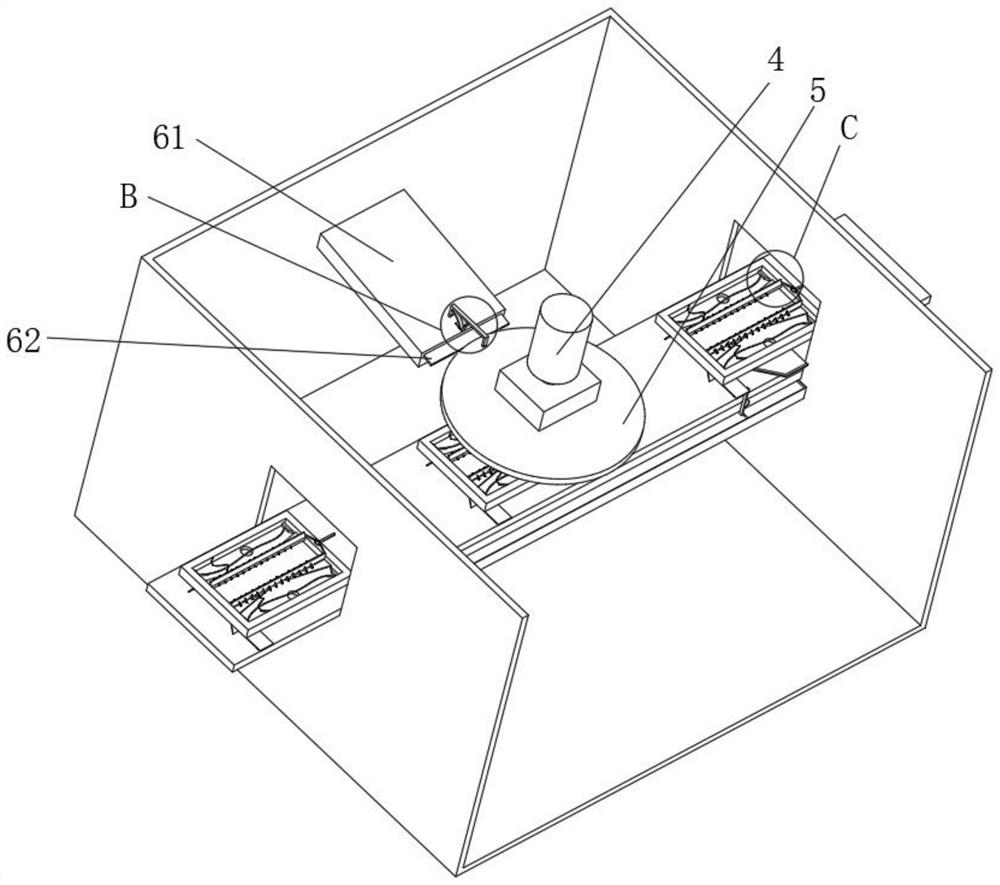

Automatic industrial cleaning method

InactiveCN108144881ATo achieve the purpose of cleaningRealize pipeline operationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineering

The invention belongs to the technical field of cleaning, and particularly relates to an automatic industrial cleaning method. The automatic industrial cleaning method includes the steps that firstly,cleaning liquid is prepared; secondly, the cleaning liquid is made; thirdly, a feeding box is prepared, to-be-cleaned nuts are placed in the feeding box, and a rotating disk for automatically suckingthe nuts in the feeding box is installed above the feeding box; and a cleaning mechanism for cleaning the outer walls and the inner walls of the nuts at the same time in the rotating process and an intermittent mechanism for making the cleaning mechanism intermittently leave the nuts on the rotating disk are installed on one side of the rotating disk; fourthly, the cleaning liquid made in the second step is added in the cleaning mechanism in the third step; fifthly, secondary cleaning is performed; and sixthly, drying is performed. By means of the scheme, the cleaning effect of the nuts can be improved.

Owner:重庆创赢清洗有限公司

Rust removal and prevention agent as well as synthesis process and application thereof

ActiveCN114164036AEfficient removalAvoid contactLubricant compositionO-Phosphoric AcidALUMINUM PHOSPHATE

The invention relates to a rust removal and prevention agent as well as a synthesis process and application thereof. The rust removal and prevention agent is prepared from PSHAD, stearic acid, oleic acid, nano-zinc oxide, aluminum metaphosphate, vinyl acetate, potassium pyrophosphate, triethanolamine, diethanol amine, laurate, ethyl methacrylate, butyl methacrylate, a coupling agent and water, wherein the ratio of m1 to m2 to m3 is (47-53): (18-22): (15-17). M1 is the total mass of PSHAD, nano zinc oxide, aluminum metaphosphate and potassium pyrophosphate, m2 is the total mass of stearic acid, oleic acid, triethanolamine and diethanol amine, and m3 is the total mass of vinyl acetate, laurate, ethyl methacrylate and butyl methacrylate; pSHAD is a mixture of phosphoric acid and aluminum zinc phosphate. The rust removing and preventing agent can effectively remove rust on the metal surface at the same time, enables the rusted metal surface to be bright and flat, and can generate a compact protective film on the metal surface to prevent the metal surface from making contact with the outside.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Antirust composite additive for lubricating oil and preparation method

The invention relates to the field of lubricating oil additives, and discloses an antirust composite additive for lubricating oil and a preparation method thereof. The preparation method comprises thefollowing steps: (1) adding a polyether carboxylic acid derivative and magnesium-aluminum hydrotalcite into alkali liquor, and carrying out heating, stirring, ageing, filtering and washing to obtainpolyether carboxylic acid derivative intercalated hydrotalcite; (2) adding the polyether carboxylic acid derivative intercalated hydrotalcite, 2,4-toluene diisocynate and an amine chain extender into4,4'-diaminodiphenyl ether, and carrying out heating and kneading to obtain a polyurea dispersion material; and (3) uniformly grinding and dispersing the polyurea dispersion material, barium alkyl benzene sulfonate, calcium alkyl benzene sulfonate, ammonium borate, zinc dialkyl dithiophosphate, nanometer polytetrafluoroethylene and base oil 150BS to obtain the antirust composite additive for lubricating oil . The polyether carboxylic acid derivative intercalated hydrotalcite is dispersed in a polyurea system to prepare the antirust composite additive, so when being used for lubricating oil, the antirust composite additive has better antifriction and antiwear properties and can form a stable antirust protective film to realize long-term rust prevention.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Hardware polishing device with antirust function

PendingCN114770292AAvoid Spraying EffectsTo achieve anti-rust effectGrinding machinesGrinding feedersEngineeringGrinding

The invention discloses a hardware grinding device with an anti-rust function, and relates to the technical field of hardware grinding. The hardware grinding device with the antirust function comprises a device body, a supporting plate is fixedly installed on the inner wall of the device body, a conveying belt is arranged on the supporting plate, a driving device is fixedly installed at the top of the inner wall of the device body, and a grinding plate is fixedly installed at the output end of the driving device. According to the hardware grinding device with the anti-rust function, a grinding plate can be driven by the driving device to move up and down, after grinding is completed, the grinding plate can be driven by the driving device to move upwards, a connecting rod and a pull rod can be driven to move upwards when the grinding plate moves upwards, and a sealing plate can be driven to move upwards after the pull rod moves upwards; and at the moment, a discharging opening of the sealing plate communicates with a spray head, so that the anti-rust oil in the storage frame can be sprayed out of the spray head, and therefore the anti-rust oil can be sprayed to the polished hardware in time to achieve the anti-rust effect.

Owner:蚌埠滤佳纳米科技有限公司

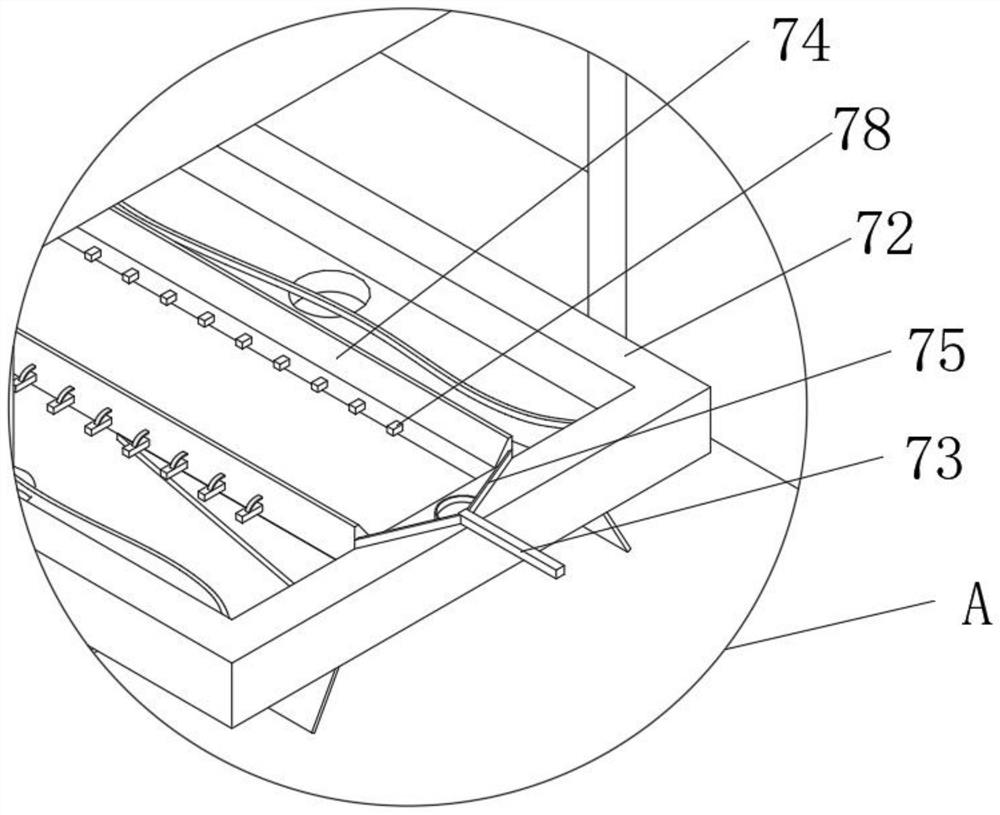

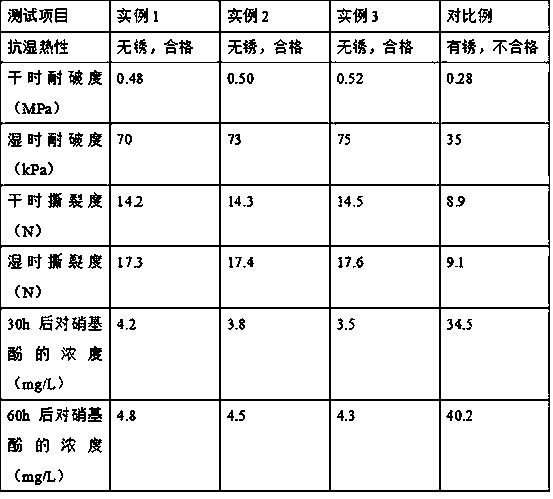

Preparation method of damp-proof slow-release antirust paper

InactiveCN108560002AAvoid enteringNot prone to corruptionLaminationLamination apparatusHigh concentrationAdhesive

The invention discloses a preparation method of damp-proof slow-release antirust paper, and belongs to the technical field of antirust paper preparation. Limestone water is used for neutralizing and precipitating calcium phytic acid from broad beans, the calcium phytic acid and pomegranate peels are subjected to the action of active microorganisms in rottenwood to obtain a mixed fermentation solution containing phytic acid and tannin, in addition, the tannin can be bound with protein in a protein adhesive to generate a dense, flexible and impermeable leather layer not likely to decay; proteinis extracted from soybeans to be subjected to acid heat modification, the soybean protein molecular chains are extended, the soybean protein is subjected to alkali modification under the high concentration of a sodium hydroxide solution, some soybean proteins are subjected to hydrolysis, p-nitrophenol and the alkali protein adhesive react to generate sodium para-nitrophenolate, the sodium para-nitrophenolate can be gasified, a layer of special complex is generated on the surface of metal through a rust-proof inner film, particles of the PET film can be distributed and loosened in the gasification process of the sodium para-nitrophenolate, a gas-phase corrosion inhibitor can be slowly released, and the application prospect is wide.

Owner:裴泽民

A kind of water-soluble metal antirust agent and preparation method thereof

The invention provides water soluble metal antirusting agent. The water soluble metal antirusting agent comprises the following constituents in part by mass: 7 to 10 parts of triethanolamine, 3 to 5 parts of zinc chloride, 2 to 3 parts of sodium borate, 1 to 2 parts of sodium methoxide, 4 to 6 parts of sodium carbonate, 3 to 5 parts of stannous mono-sulphate, 1 to 2 parts of diethanol amine, 1 to 2 parts of isopropyl alcohol, 10 to 15 parts of ethyl alcohol, and 70 to 80 parts of water. The invention further provides a preparation method of the antirusting agent. By soaking metal work pieces in the water soluble metal antirusting agent, a layer of oxide protective film can be formed on the surface of metal, the tissue structure is dense, and particles are fine, so that the effect of rust protection is achieved; the water soluble metal antirusting agent is short in film formation time and good in drying capacity, and can form a film in 1 to 2 minutes only; the water soluble metal antirusting agent can ensure that metal keeps rustless within 6 months in normal environment.

Owner:TONGXIANG TONGDE ELECTRIC POWER FITTING

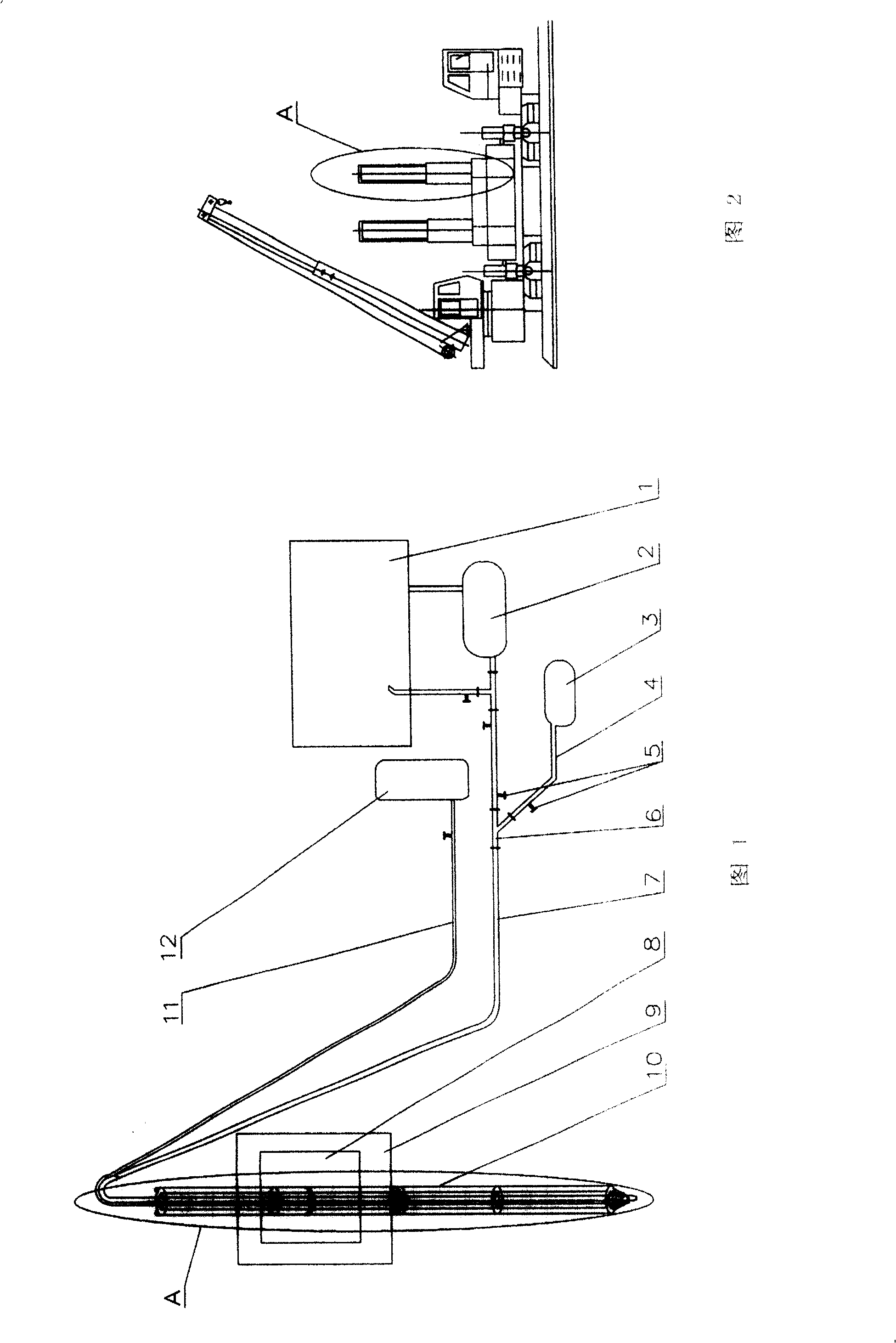

After-grouting self-guiding hole PHC tubular pole tip anti-rusting cap construction device and construction process

InactiveCN100432341CBlocking corrosionTo achieve anti-rust effectBulkheads/pilesPressure transmissionStructural engineering

The invention relates to a pouring self-priming hole PHC tube pile sharp anti-rust cap constructing device, which is connected to the static hydraulic compress machine formed by water tank, multistage eccentric pump, high-pressure transmission tube, clamper, transmission tube, PHC hollow tube pile, high-pressure gas transmission tube and air compressor, with water jet gas jet priming hole, wherein the high-pressure pouring pump via high-pressure pouring tube and three-way tube is connected to the high-pressure water transmission tube; one-way valves are mounted between three-way tube and multistage eccentric pump, three-way tube and high-pressure pouring pump; when the PHC chamber tube pile is fed to the holding layer, and stopping jetting water and gas, starting the high-pressure pouring pump; using high-pressure pouring tube, three-way tube and high-pressure water transmission tube to feed some cement pulp to the pile sharp pump; filling steel pile sharp inner and outer; the forming anti-rust cap packed by cement pulp at the surface of pile sharp, to separate the pile sharp and soil, to resist rust and strengthen foundation, to improve its carrier force.

Owner:钱勇 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com