Antirust packaging material and preparation method thereof

A technology for anti-rust packaging materials and active materials, applied in the field of anti-rust packaging materials, can solve the problems of reducing the barrier and sealing performance, high construction difficulty, material layering, etc., and achieve the effect of easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

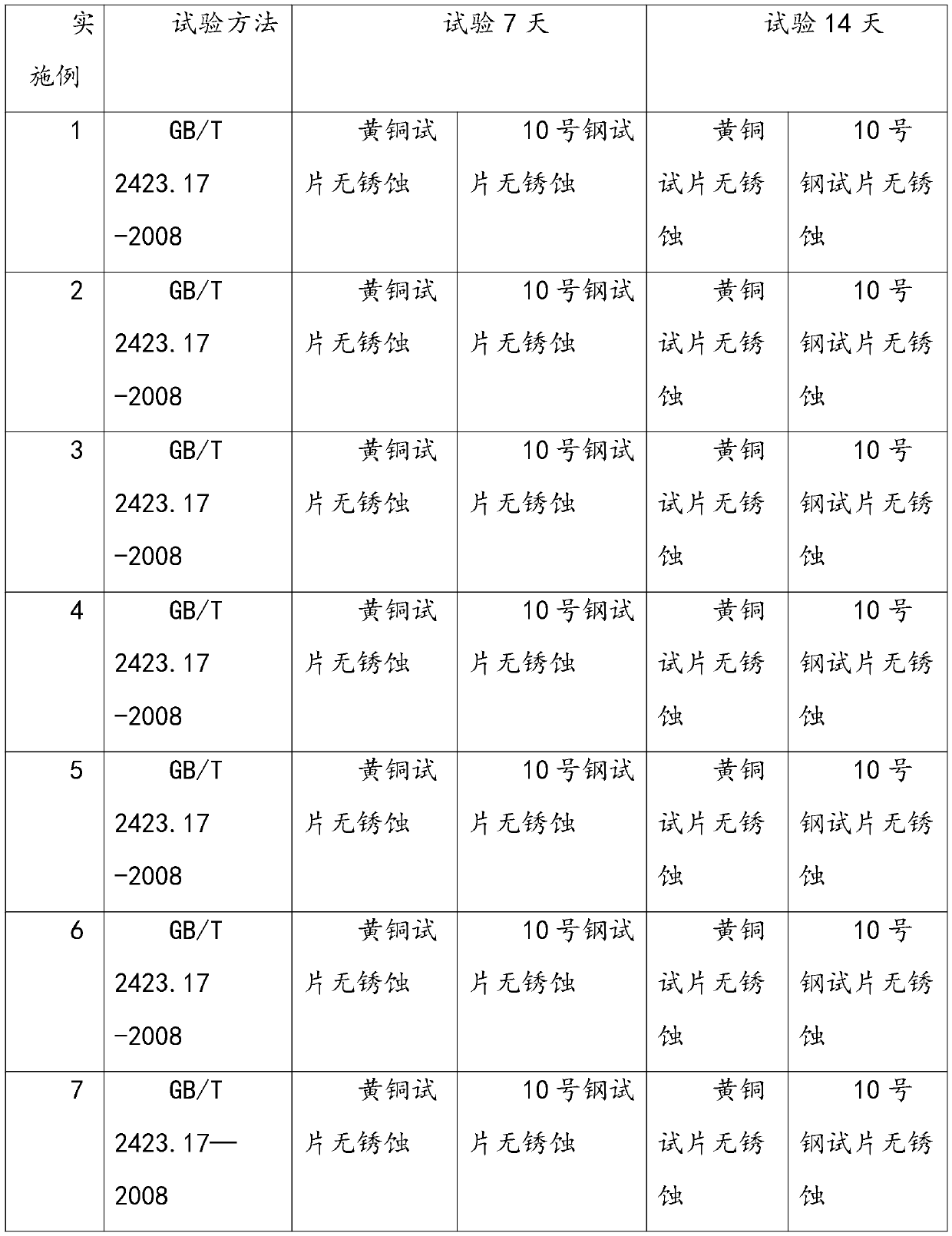

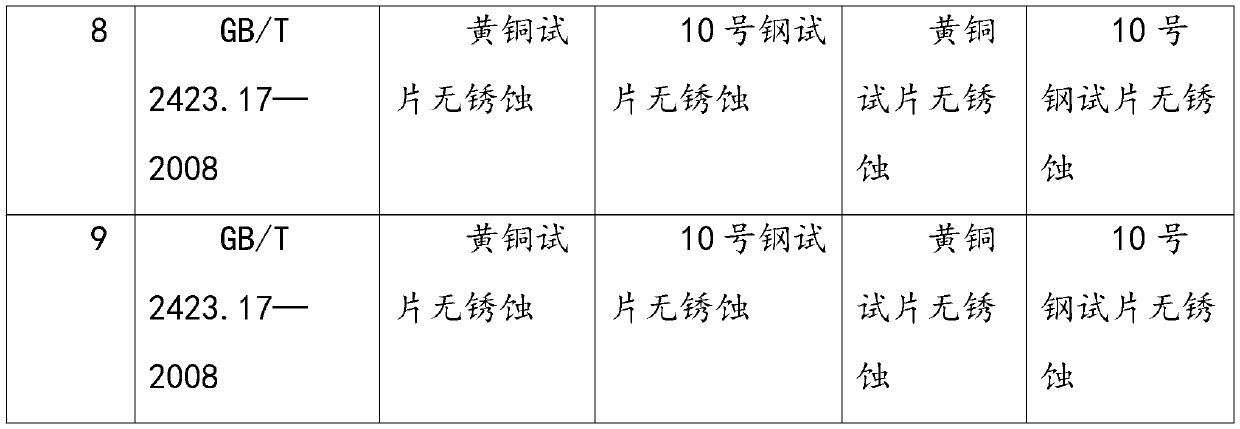

Examples

preparation example Construction

[0039] The present invention provides a kind of preparation method of antirust packaging material on the other hand, comprises the steps:

[0040] (1) Mix and stir 50-100 parts of thermoplastic or elastomeric polymer substrate and 0.1-50 parts of active material to obtain a compound;

[0041] (2) The compound is melted, plasticized, extruded and granulated by an extruder to obtain a masterbatch mixed with an active material;

[0042] (3) Process the masterbatch into packaging materials through plastic molding equipment.

[0043] Further, when mixing and stirring the thermoplastic or elastomeric polymer substrate and the active material to obtain a mixture, an additive is added, and the amount of the additive added is 0.1- 30%, wherein the additives are plasticizers, lubricants, antioxidants, light stabilizers, coupling agents, compatibilizers, pigments, flame retardants, antistatic agents, foaming agents, fillers and reinforcing agents one or more of.

[0044] The antirust ...

Embodiment 1

[0047] The present embodiment provides a kind of antirust packing material, comprises the following components of following parts by weight:

[0048] 95 parts of polyethylene LLDPE, 5 parts of copper powder; Among them, the microstructure of copper powder is flake, the average size of the horizontal axis is 10um, and the vertical axis is 100nm.

[0049] Present embodiment provides a kind of preparation method of antirust packaging material on the other hand, comprises the steps:

[0050] (1) Mix and stir 100 parts of polyethylene LLDPE and 5 parts of copper powder to obtain a compound;

[0051] (2) Pass the mixture through a twin-screw extrusion granulator, and at a processing temperature of 120-220° C., melt, plasticize, extrude and granulate the mixture to obtain a masterbatch 1 mixed with active materials;

[0052] (3) Process the masterbatch 1 through plastic molding equipment at a processing temperature of 145-220° C. to form a film packaging material with a thickness of...

Embodiment 2

[0054] The present embodiment provides a kind of antirust packing material, comprises the following components of following parts by weight:

[0055] 96 parts of polyurethane, 4 parts of iron powder; wherein, the microstructure of the iron powder is spherical, with an average diameter of 5um.

[0056] Present embodiment provides a kind of preparation method of antirust packaging material on the other hand, comprises the steps:

[0057] (1) 96 parts of polyurethane and 4 parts of iron powder are mixed and stirred to obtain a mixture;

[0058] (2) passing the mixture through a twin-screw extrusion granulator, and at a processing temperature of 120-220° C., melting, plasticizing, extruding and granulating the mixture to obtain masterbatch 2 mixed with active materials;

[0059] (3) Process the master batch 2 through plastic molding equipment at a processing temperature of 145-230° C. to form a film packaging material with a thickness of 80 um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com