Waterborne epoxy phosphatic zinc dust antirust paint and its preparation method

A technology of zinc epoxy phosphate and water-based epoxy, applied in the field of anti-rust paint, to achieve the effect of large adjustable range of viscosity, good permeability and adhesion, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A water-based epoxy phosphate zinc powder anti-rust paint, the anti-rust paint is composed of component A and component B in a mass ratio of 2:1:

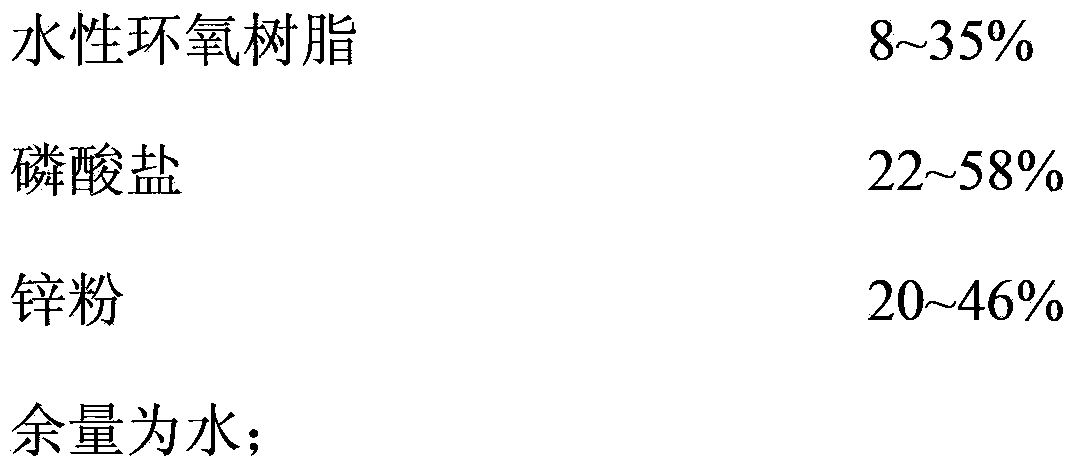

[0063] 1) The component A includes the following components by mass percentage:

[0064]

[0065]

[0066] 2) The second component is water-based epoxy curing agent AB-HGF.

[0067] The preparation method is as follows:

[0068] 1) First, mix the water-based epoxy resin, dispersant, phosphate, zinc powder, sodium nitrite, and water according to the formula amount, and then disperse, and sand to a fineness of 70μm or less;

[0069] 2) Add the remaining additives to the mixture obtained in step 1) and stir evenly. After adjusting the viscosity to 3~5Pa.S, filter and pack to obtain component A;

[0070] 3) Pack the component A and component B obtained in step 2) according to the mass ratio.

Embodiment 2

[0072] A water-based epoxy phosphate zinc powder anti-rust paint, the anti-rust paint is composed of component A and component B at a mass ratio of 8:1:

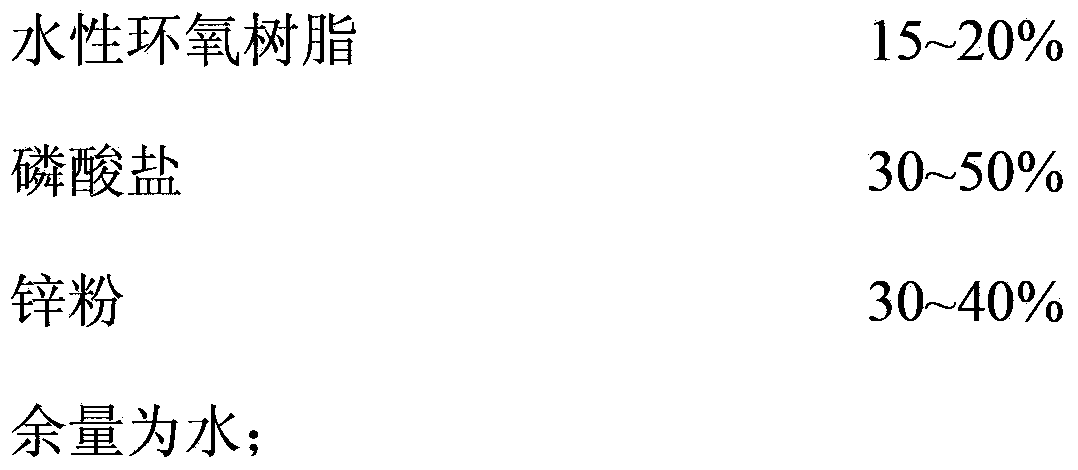

[0073] 1) The component A includes the following components by mass percentage:

[0074]

[0075]

[0076] 2) The second component is water-based epoxy curing agent AB-HGT.

[0077] The preparation method is the same as in Example 1.

Embodiment 3

[0079] A water-based epoxy phosphate zinc powder anti-rust paint, the anti-rust paint is composed of component A and component B at a mass ratio of 8:1:

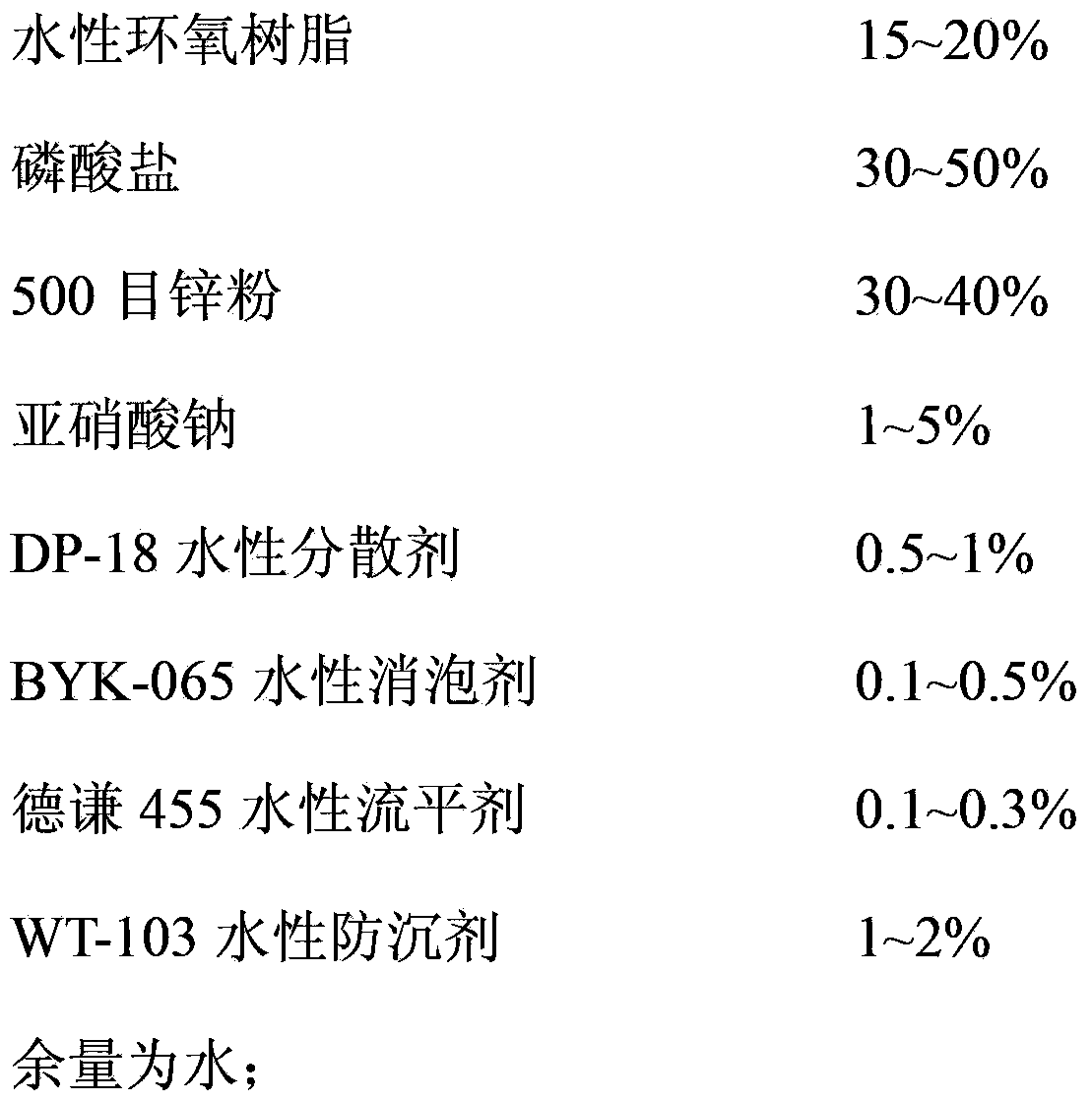

[0080] 1) The component A includes the following components by mass percentage:

[0081]

[0082] 2) The second component is water-based epoxy curing agent AB-HGT.

[0083] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com