Composite material structure and production method thereof

A technology of composite materials and production methods, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of restricted steel use, rust, safety performance decline, etc., to achieve enhanced tensile strength , high yield resistance, and the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

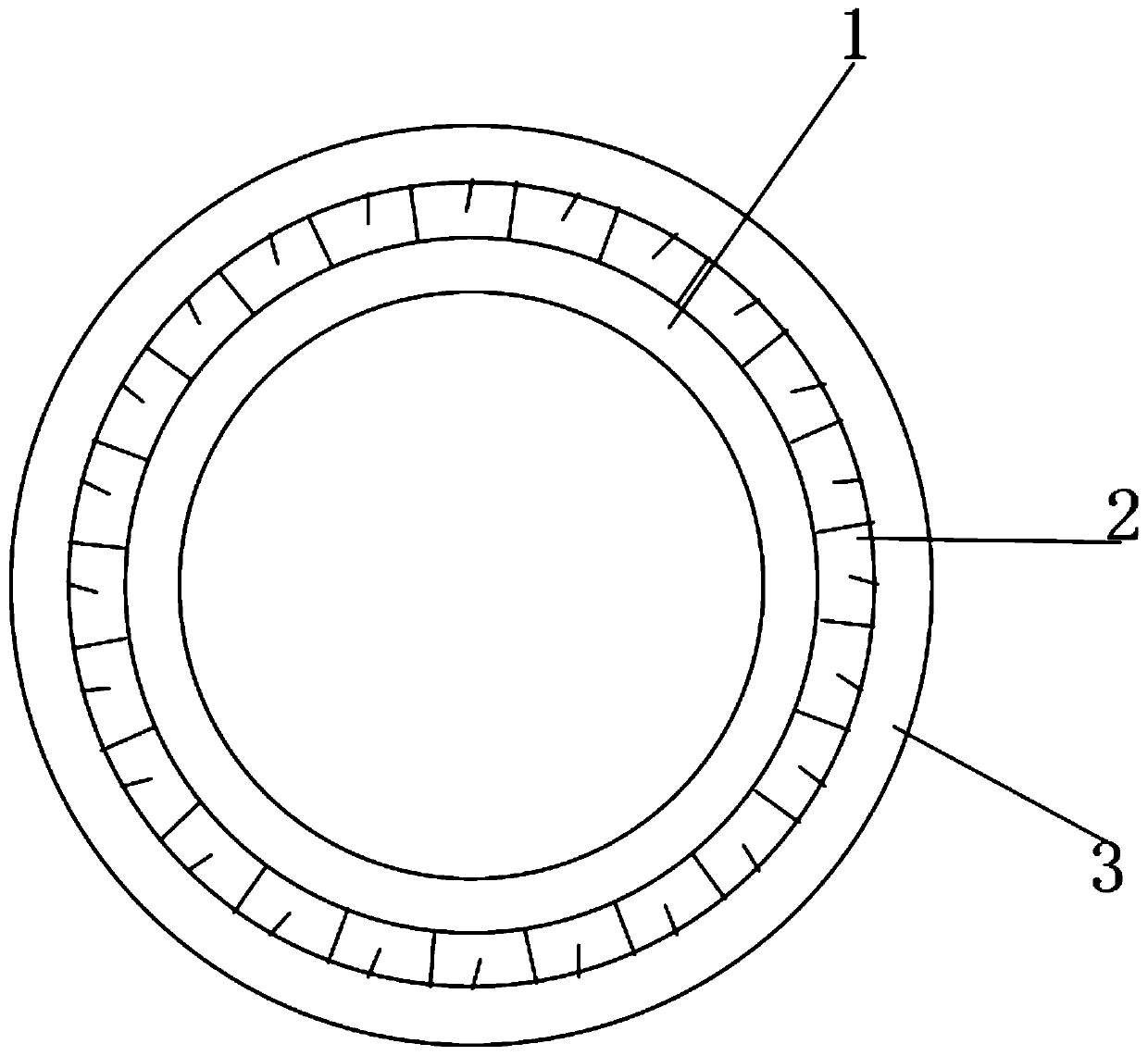

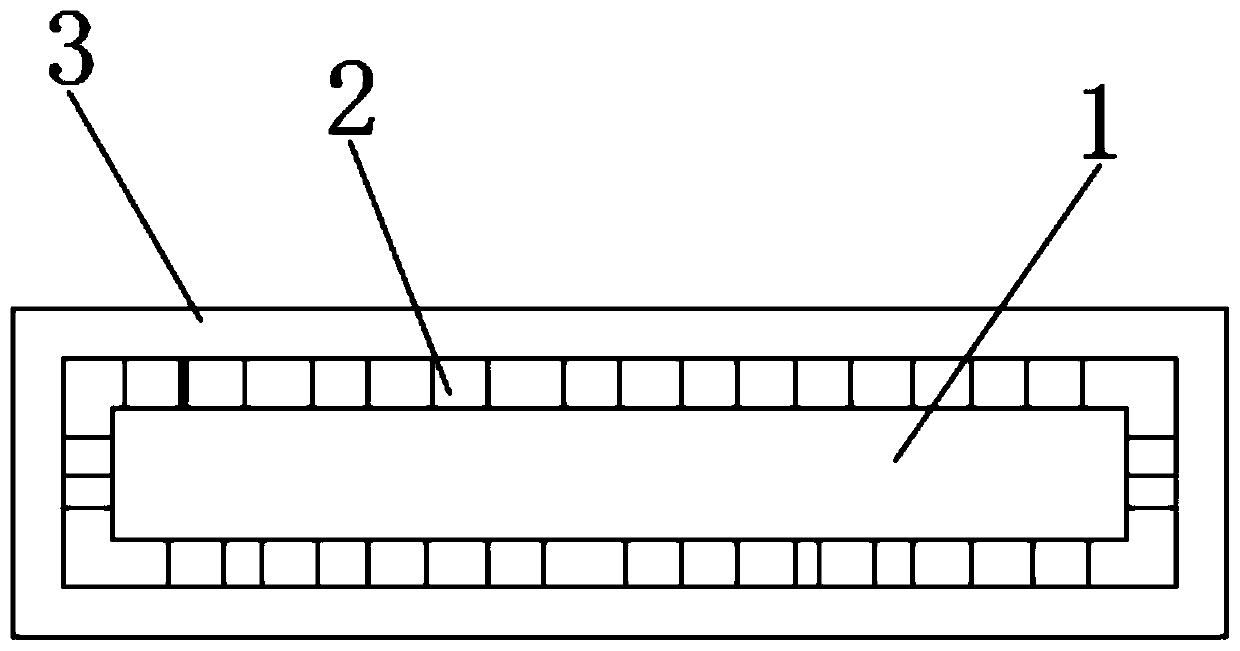

[0082] Such as Figure 1 to Figure 4 As shown, this embodiment provides a composite material structure, the surface of the matrix 1 is coated with a carbon fiber material 2 and a prepreg 3, and the prepreg 3 is impregnated into the carbon fiber material 2 to form a composite layer.

[0083] In this embodiment, the surface of the matrix is covered with carbon fiber material and prepreg, and the technical means of impregnating the prepreg into the carbon fiber material to form a composite layer is adopted. Therefore, the yield resistance is high, the strength is high, and the strength is enhanced. Tensile strength, becoming lighter and more corrosion-resistant, can greatly save steel during processing, making this material not only widely used in aerospace, aviation, automobiles, electronics, machinery, chemicals, textiles and other civil industries , sports equipment and leisure products and other fields, it can also be used in military fields such as aircraft manufacturing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com